Surgical instrument comprising bearing

A surgical tool and tool technology, applied in the field of surgical tools, can solve the problems of time-consuming and cost-consuming tool users, and the inability to use the shell or handpiece as expected, so as to achieve high availability and reliability, save cost and/or time , the effect of reducing failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiments of the present disclosure will be described below based on the drawings.

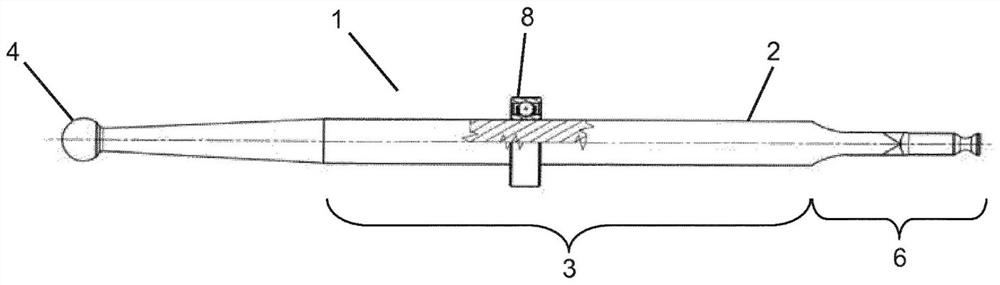

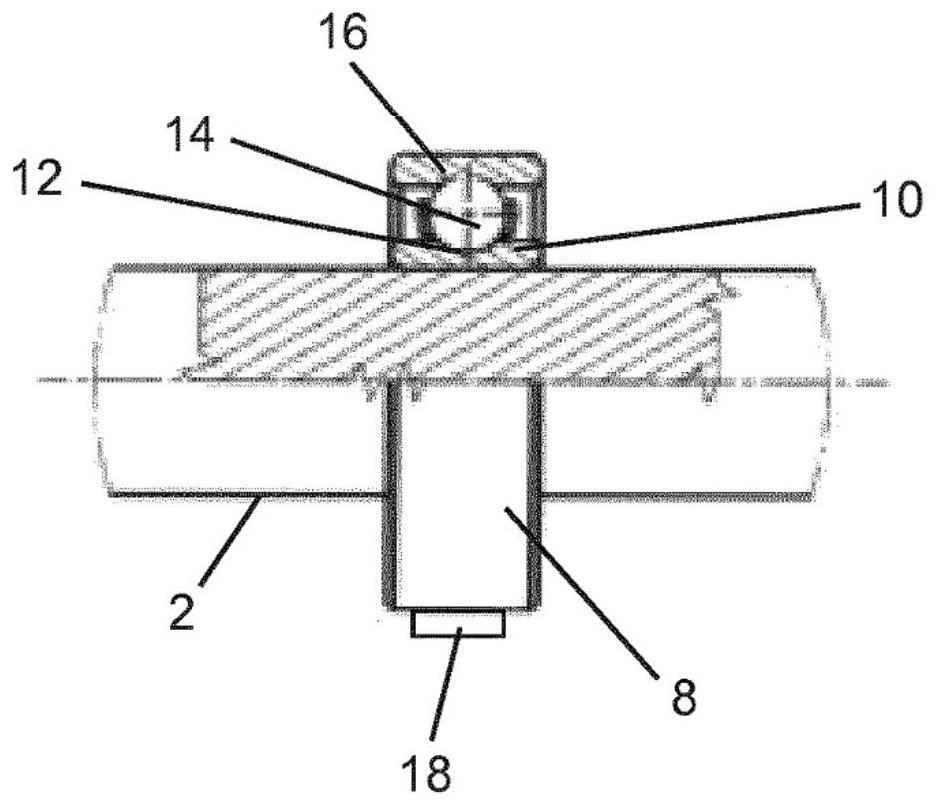

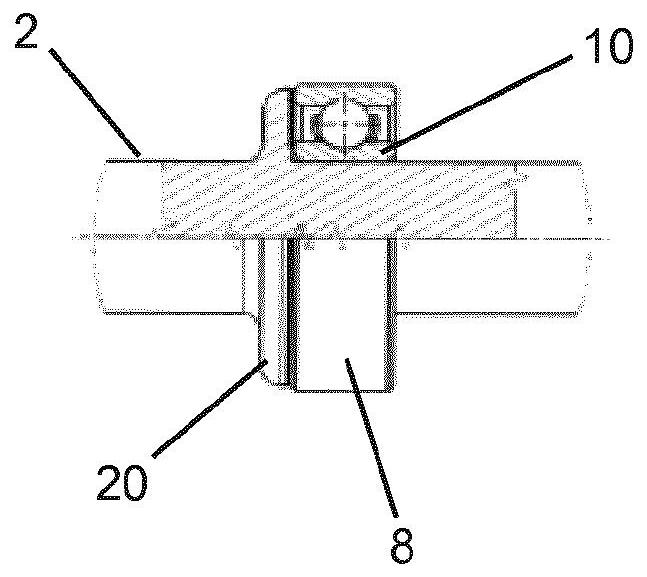

[0038] Figure 1A A surgical milling tool 1 is shown with a tool shaft 2 having a main section 3 , an actuator 4 on the distal end section and a coupling structure 6 on the proximal end section. The actuator 4 is embodied here as a milling cutter, but it could also be a drilling machine. The tool shaft 2 is tapered towards its distal end section. The radial dimension of the coupling structure 6 is narrower than that of the tool shank 2 for easy insertion into a housing or handpiece (not shown). A drive (not shown) is provided in the housing, with which the tool 1 can be coupled via the coupling structure 6 in such a way that the tool takes over the rotational movement caused by the drive. In the case of rotation of the tool 1, a bearing mechanism between the tool 1 and the housing is required. According to the invention, therefore, a pivot bearing 8 is provided on the tool shaft 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com