A roller type slide button switch

A button switch and roller type technology, which is applied in the field of roller slider button switches, can solve the problems of slider melting, difficult processing, and slider wear, and achieve the effects of not being easy to wear, improving the feel of the lever, and increasing the rated load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

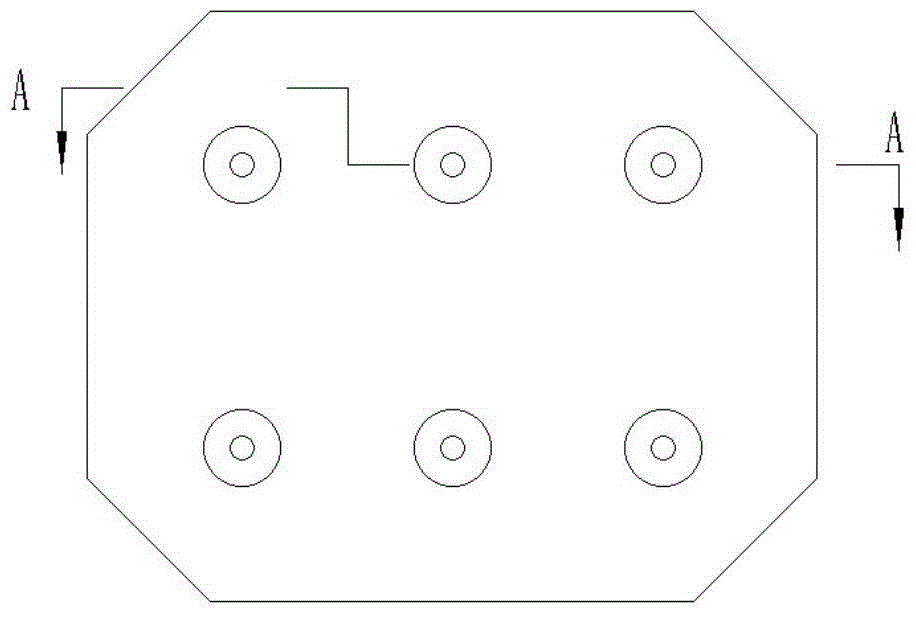

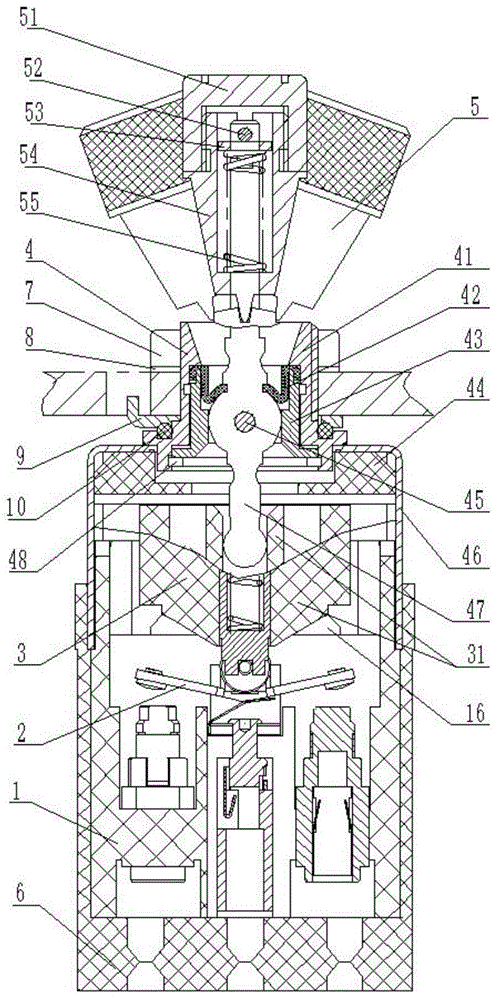

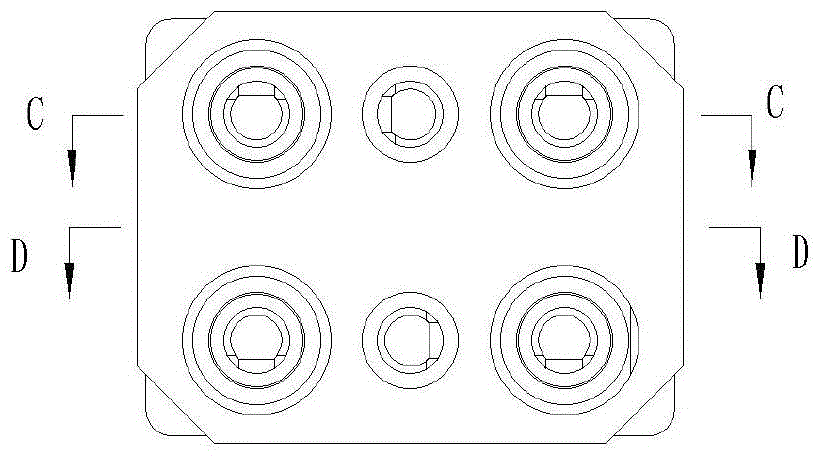

[0027] Such as Figure 1 to Figure 10 The shown roller type slider button switch includes a base assembly 1, a moving contact piece assembly 2, a shift block assembly 3, a reversing device 4 and a lock handle assembly 5; the moving contact piece assembly 2 is installed through a bracket 14 On the middle conductor assembly 11 of the base assembly 1, the shift block assembly 3 is movably installed in the metal casing 46 of the reversing device 4, and the lower end of the handle 47 of the reversing device 4 is inserted into the dial of the shift block assembly 3. In the groove 35, the upper end of the handle 47 is fixedly installed with the lock handle assembly 5; the shift block 31 of the shift block assembly 3 and the limit block 16 of the base assembly 1 are matched by sawtooth, and the roller 34 of the shift block assembly 3 Plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com