Linear ball guide sleeve

A technology of balls and guide bushes, applied in the direction of belts/chains/gears, mechanical equipment, transmission devices, etc., can solve the problems of increasing production costs, reducing production efficiency, shortening service life, etc., to prolong service life, increase rated load, Effect of improving lubricating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

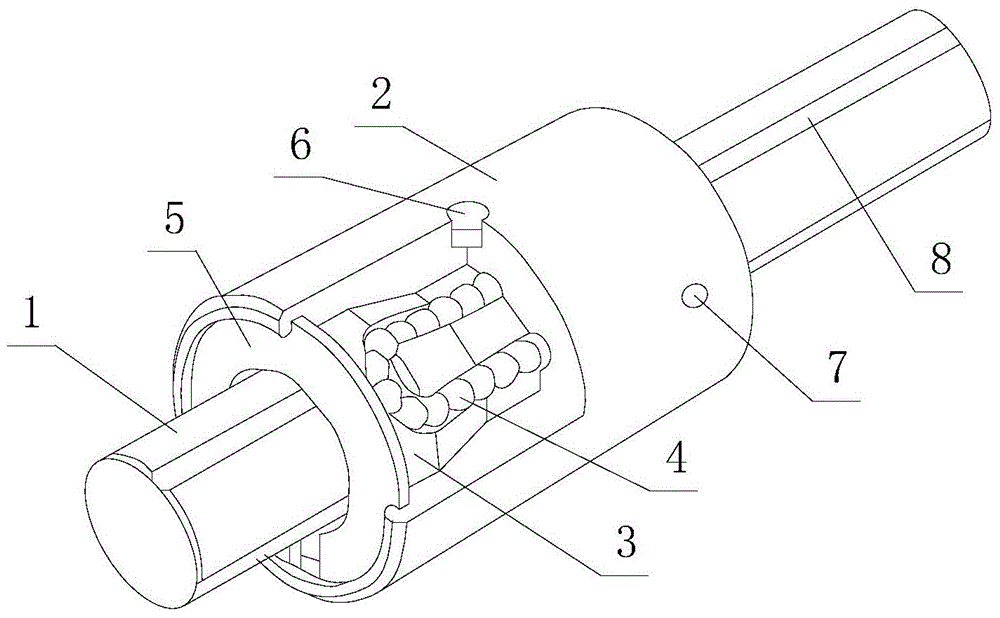

[0013] The present invention will now be further described in conjunction with the accompanying drawings and preferred embodiments. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0014] like figure 1 The shown linear ball guide bushing includes a rotating shaft 1 and a bearing sleeve set outside the rotating shaft 1. The bearing sleeve includes a cage 3 and a bearing sleeve shell 2, and balls are arranged between the cage 3 and the bearing sleeve shell 2. 4. There are stop rings 5 at both ends of the bearing sleeve, pin holes 6 are provided outside the bearing sleeve shell 2, and pins are inserted into the pin holes 6 to connect the cage 3 and the bearing sleeve shell 2; Arc rolling channel 8.

[0015] The bearing housing shell 2 is provided with an oil filling hole 7 for injecting lubricating oil; the cag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com