Spliced variable-load hoisting mechanism

A hoisting mechanism and splicing technology, which is used in elevators, elevators in buildings, and lifting equipment in mines, etc., can solve the problems of low work efficiency and high energy consumption, and achieve compact structure, reduce energy consumption, and reduce motors. load effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

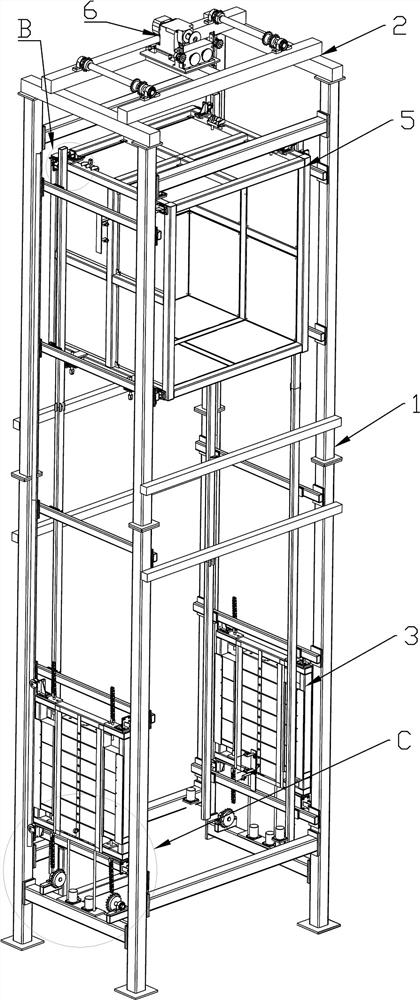

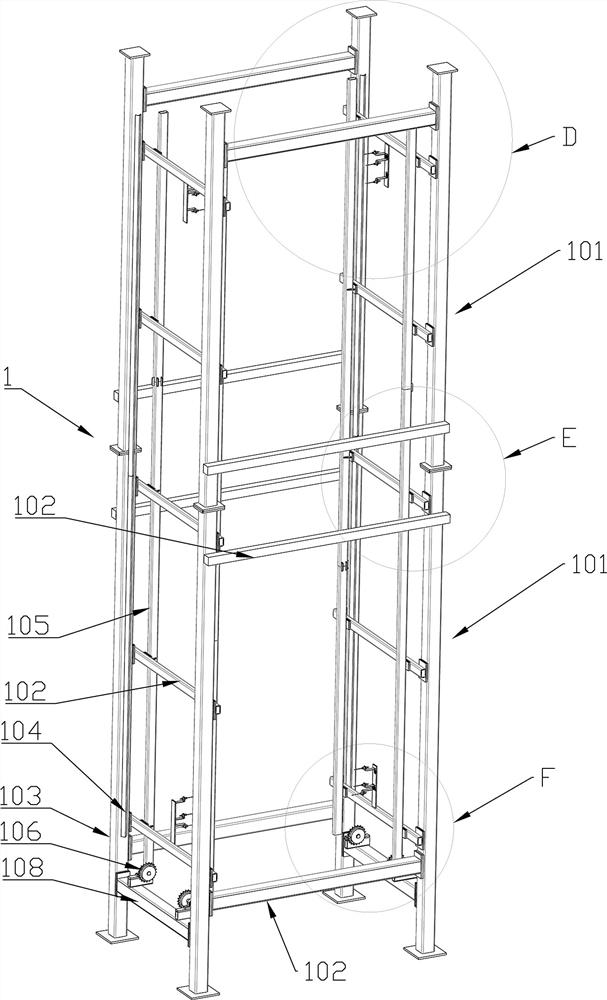

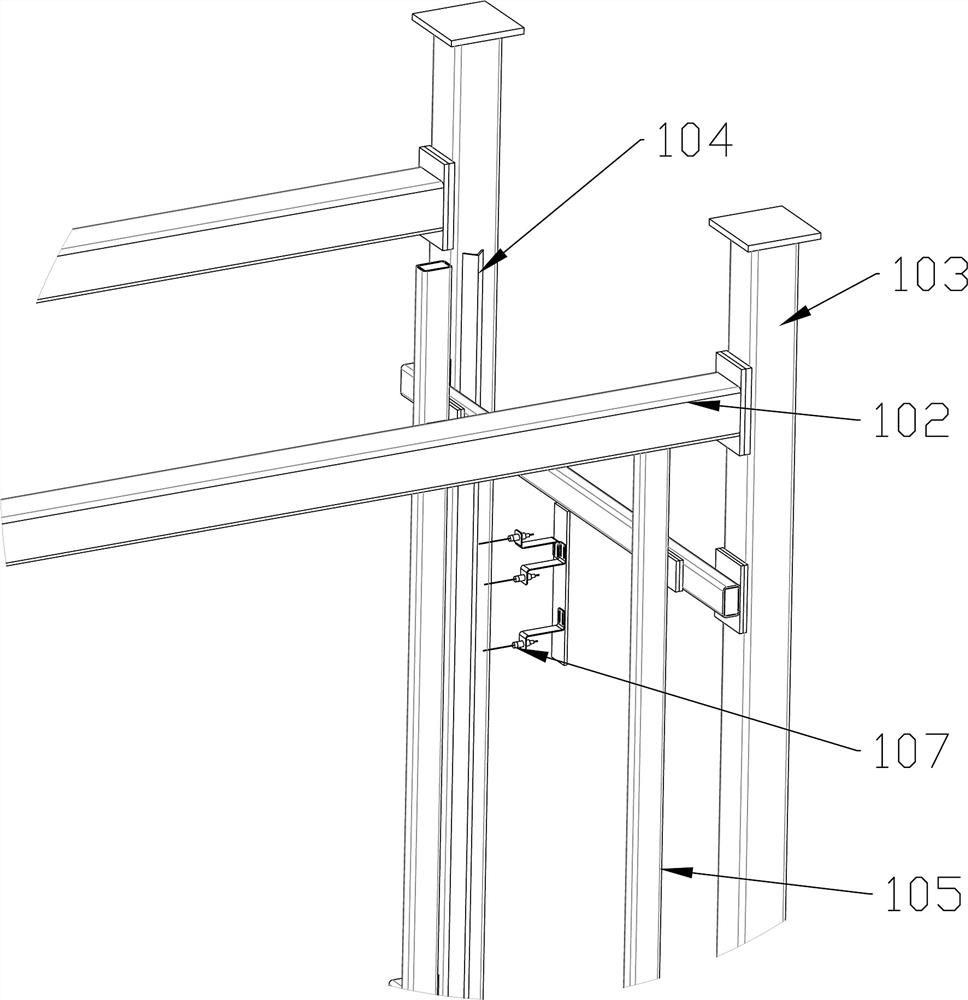

[0038] Such as Figure 1-16 , a splicing type variable load lifting mechanism, including a vertical outer frame 1, the vertical outer frame 1 includes a plurality of meta-frames 101 spliced up and down, and the meta-frames 101 are connected by flanges, and can be stacked in multiple layers to adapt to different buildings Height, the top of the vertical outer frame 1 is provided with a driving assembly 2, and the inside of the vertical outer frame 1 is provided with a car assembly 5, the car assembly 5 is slidingly connected with the vertical outer frame 1, and the driving assembly 2 drives the car assembly 5 to move up and down , the two sides of the vertical outer frame 1 are provided with a counterweight mechanism 3, the counterweight mechanism 3 is slidingly connected with the vertical outer frame 1, the counterweight mechanism 3 is connected with the car assembly 5, and the sliding direction of the counterweight mechanism 3 and the car assembly 5 is On the contrary, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com