Bearing assembly

A technology of bearing components and bearings, applied in the direction of bearings, shafts and bearings, shafts, etc., can solve problems such as uneven passage, bearing wear, etc., and achieve the effect of simplifying assembly and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

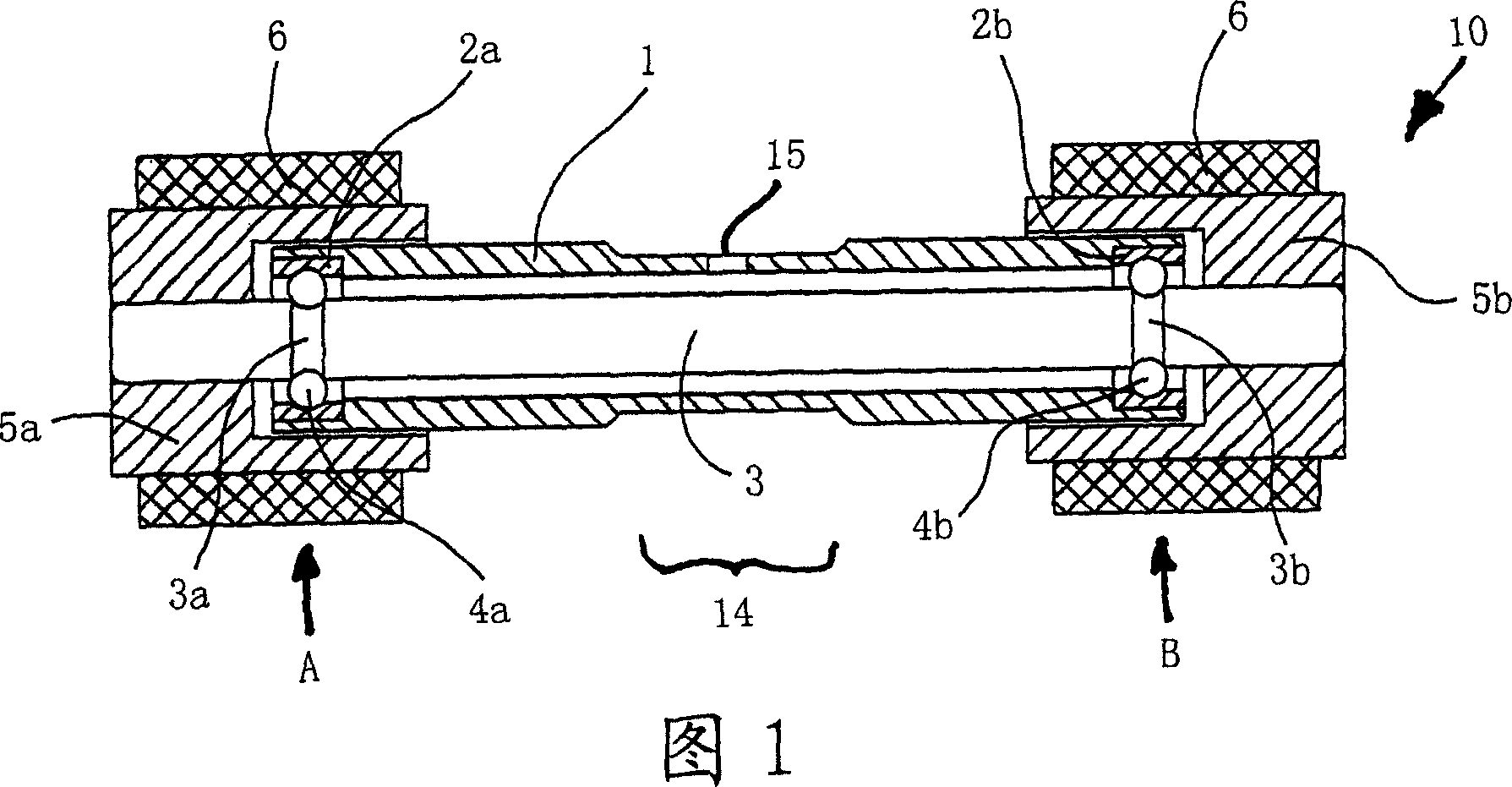

[0021] Referring now to Figures 1 and 2, there is shown a bearing assembly for a fixed roll 10 known from the prior art, Figure 1 shows a bearing assembly with a fixed intermediate piece 1 comprising a bearing outer ring 2a and 2b, bearing outer rings 2a and 2b are arranged in the ends of this intermediate piece 1 in grooves machined in the inner circumference of the intermediate piece 1 . Spindle grooves 3a and 3b are machined in the spindle 3, which form the inner rings of the bearings A and B which house the ball rows 4a and 4b and the cage. The roll bodies 5a and 5b to which the roll mantle 6 is mounted are pressed in place on the ends of the mandrel 3 protruding beyond the bearings A and B. Lubricating holes 15 are drilled in the middle of the intermediate part 1 in the region of the saddle 14 , through which the bearings A and B are lubricated.

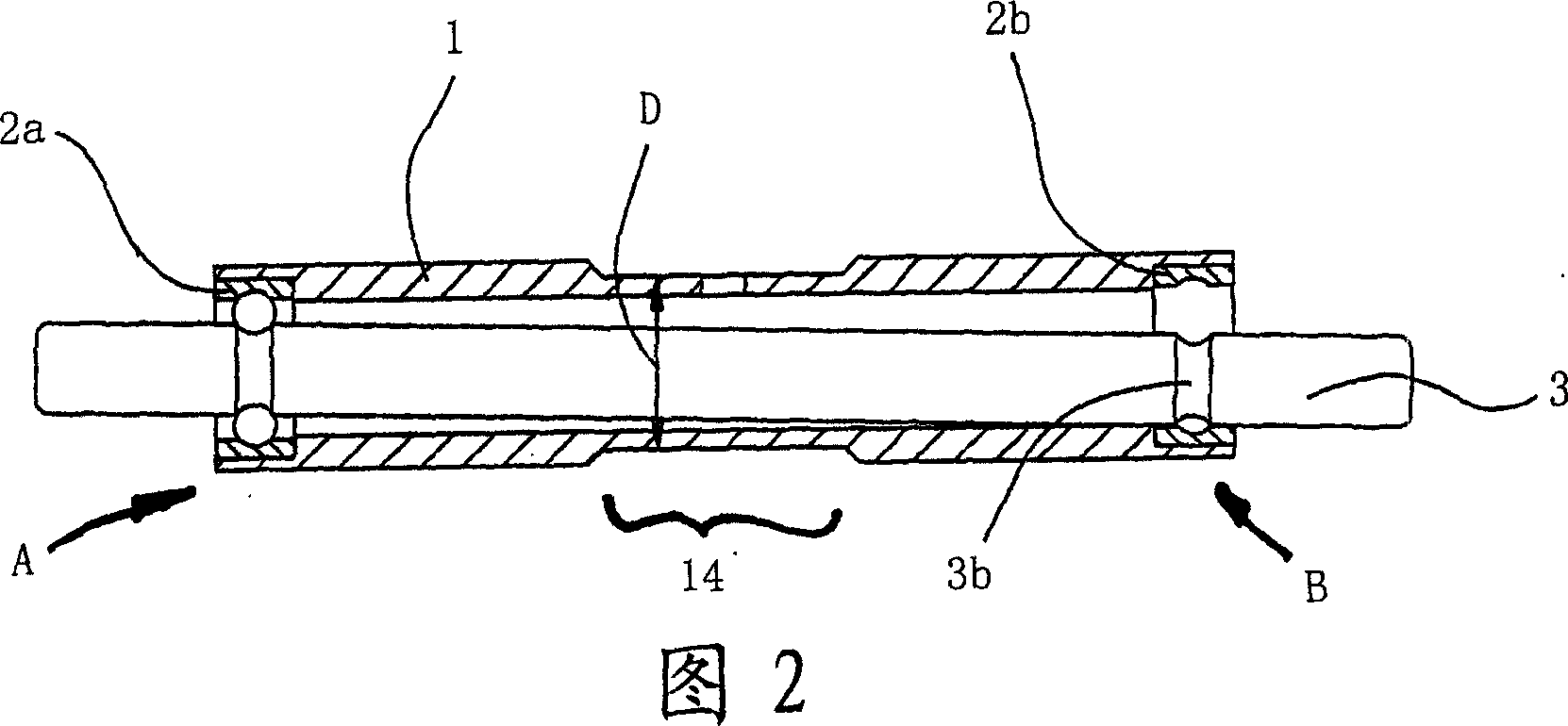

[0022] Referring now to Figure 2, in an assembly stage prior to the state shown in Figure 1 with respect to a bearing assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com