Rope movement training equipment

A technology for sports training and equipment, applied in the field of sports training equipment, can solve problems such as changing the mode of resistance output, difficulty in realizing personalized, diversified and digital training programs, and human strains.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

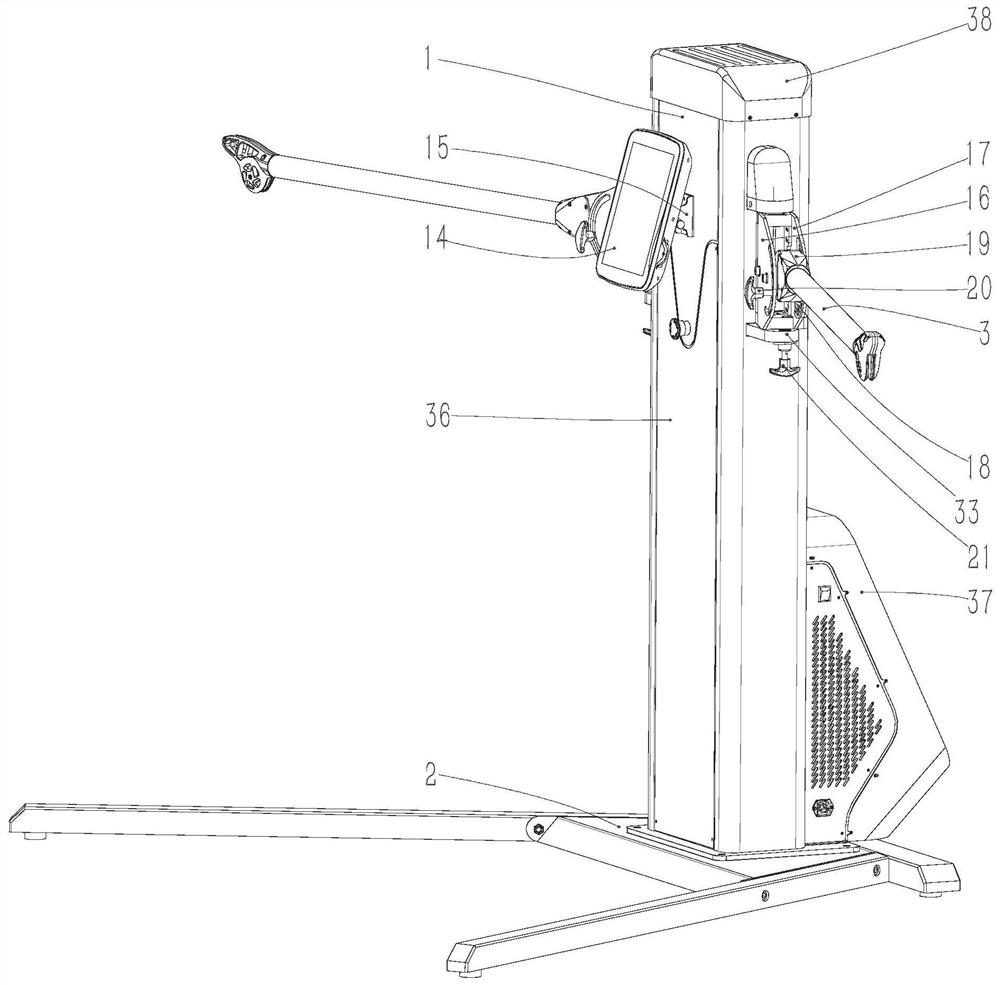

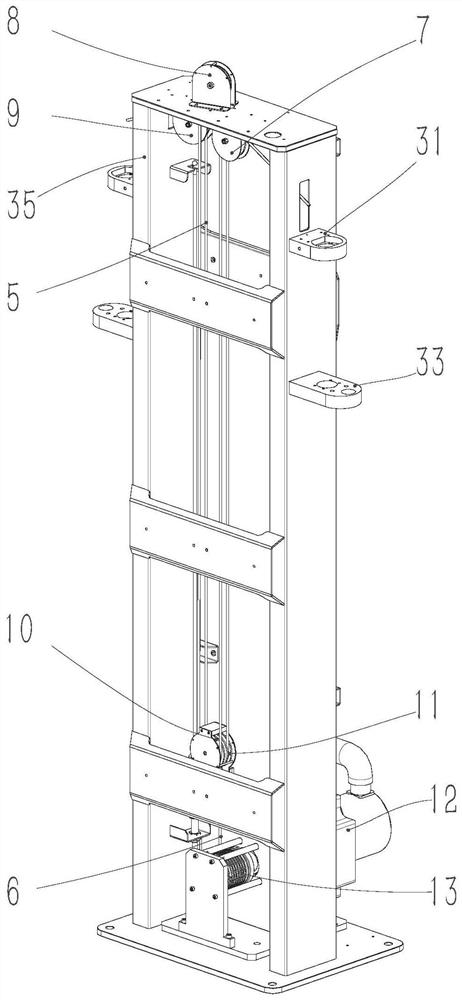

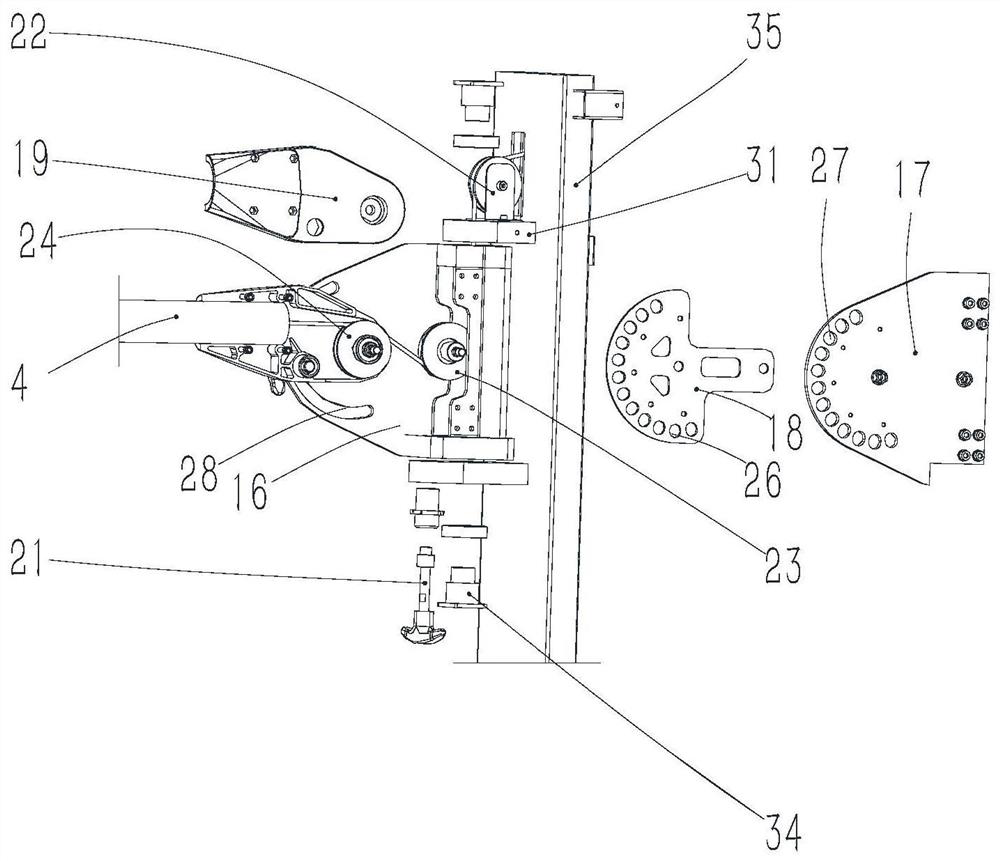

[0015] Embodiment: As shown in the figure, a rope movement training equipment includes a main body assembly 1, a base 2, a left arm 3, a right arm 4, a pulley block, a pull rope 5 and a power source assembly, and the main body assembly 1 is installed on the base 2, the left arm 3 and the right arm 4 are symmetrically installed on the left and right side walls of the main body assembly 1, the pulley block is installed inside the main body assembly 1, and the stay rope 5 is drawn from the end of the right arm 4 and passes through the right After the side arm 4 enters the main body assembly 1, and reaches the left arm 3 after going around the pulley block, it is finally fixed on the end of the left arm 3. The pulley block includes a fixed pulley block and a movable pulley block, and the movable pulley block and the power source assembly are connected by a wire rope 6. The fixed pulley block is located above the movable pulley block. The fixed pulley block includes the first fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com