Manually operated miller for notched screw surface inside hole

A milling device and helical surface technology, applied in milling machines, milling machine equipment, milling machine equipment details, etc., can solve the problems of difficult milling cutter design, difficult and high-precision machining, damage to the helical surface, etc., to ensure processing quality and accurate positioning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

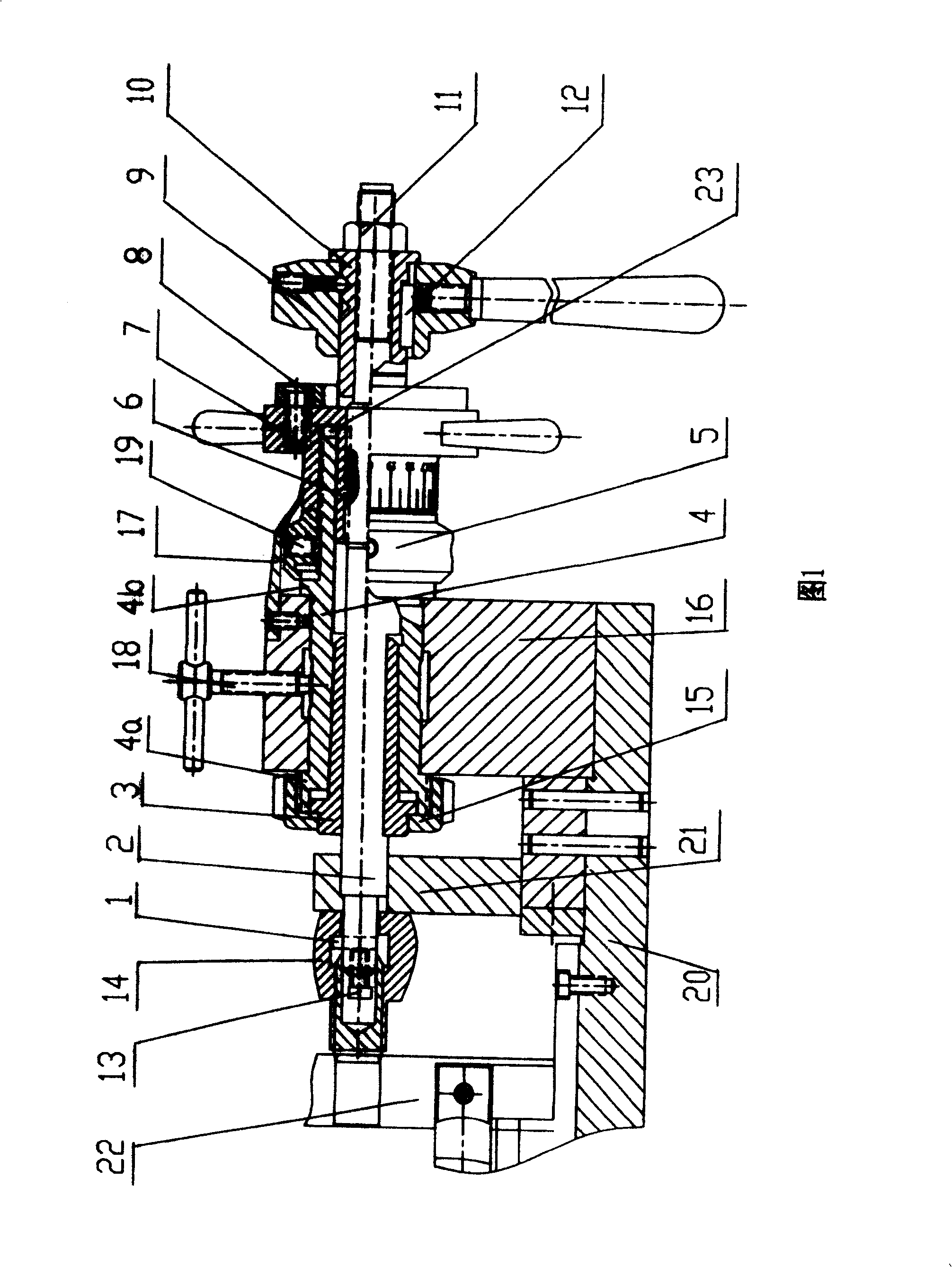

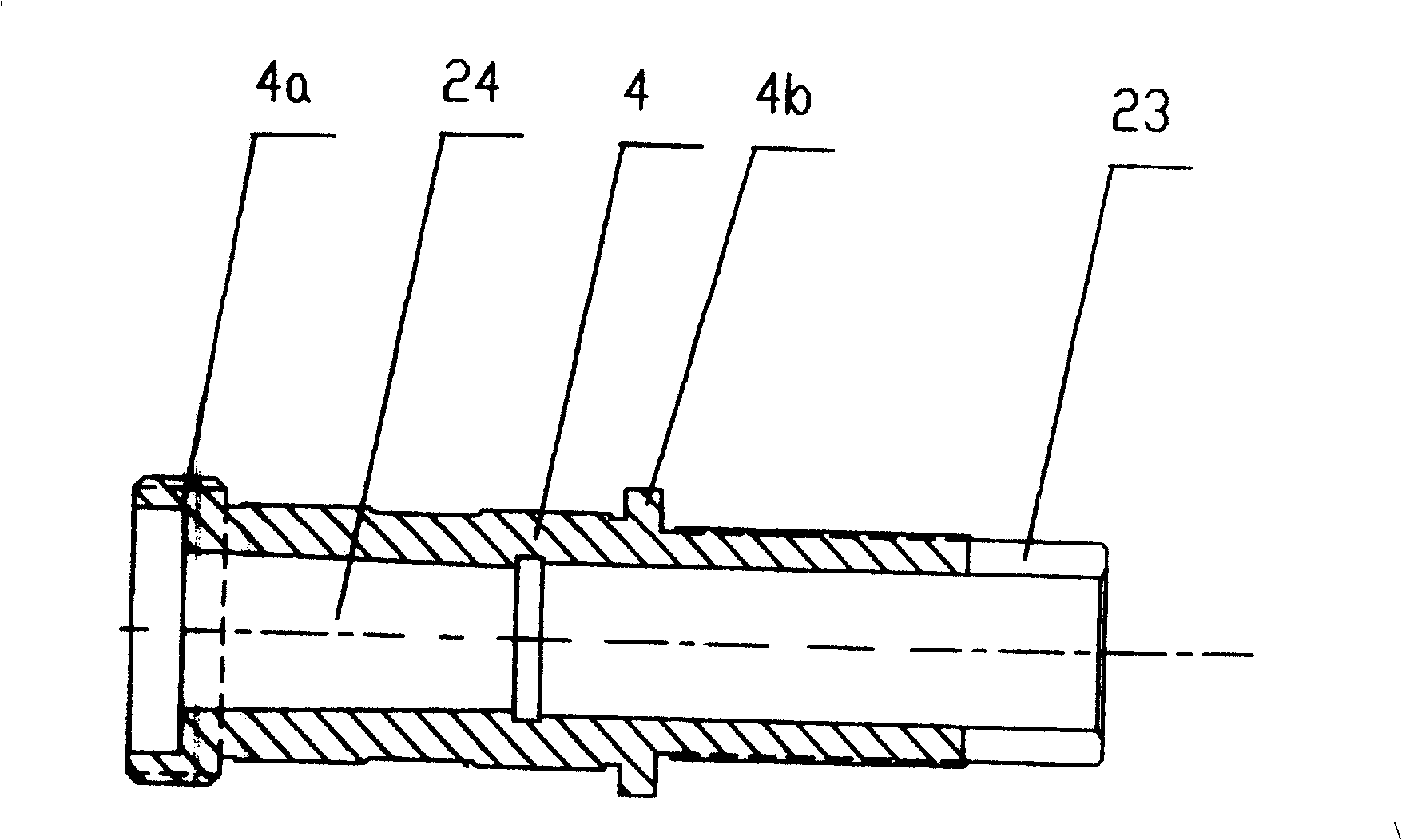

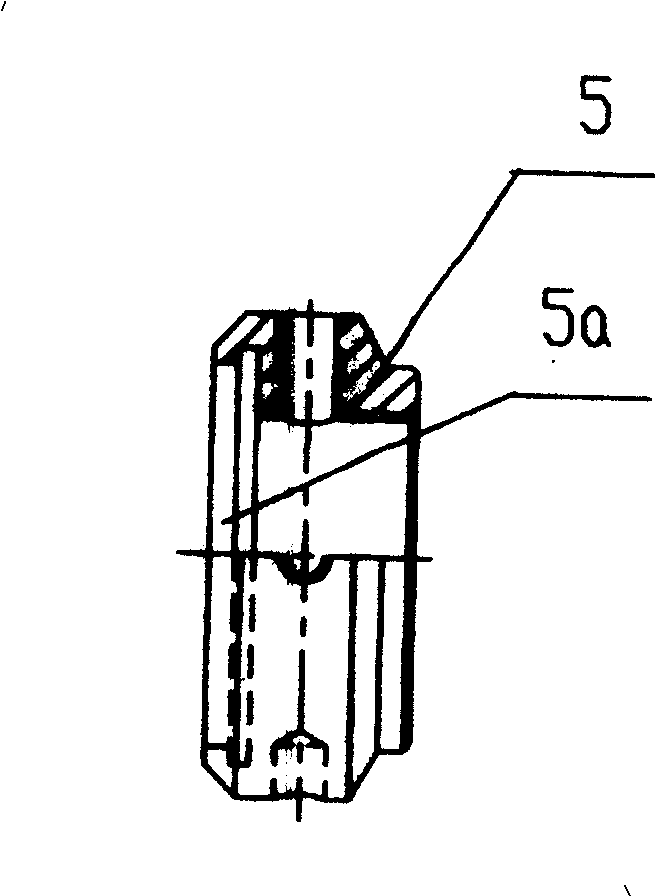

[0017] See Figure 1 to Figure 6 , the outer circumference of the sleeve 4 of the manual milling device for the concave cavity helical surface in this hole is provided with a limit step, and its limit step is two, wherein the first limit step 4a is located at the front end of the sleeve 4, and the step is set There is an external thread to connect the end cap 15, the second limiting step 4b is located in the middle of the sleeve, a groove clamped by the clamping bracket 16 is formed between the two limiting steps, and a circumferentially positioned pit is arranged in the groove, The locking screw 18 threaded with the clamping bracket 16 is tightened and pressed in the pit to form the circumferential positioning of the sleeve 4 during clamping, preventing the manual milling device of the concave cavity helicoid in the hole from producing circumferential displacement during work. The rear section of the sleeve 4 is provided with an external thread section, and the wall of the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com