A metallurgical equipment that is convenient for transportation

A technology for metallurgical equipment and gears, applied in the field of metallurgical equipment that is easy to transport, can solve problems such as damage, equipment impact deformation, heavy weight, etc., to avoid gravity inertia impact, reduce equipment damage, and prevent jamming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

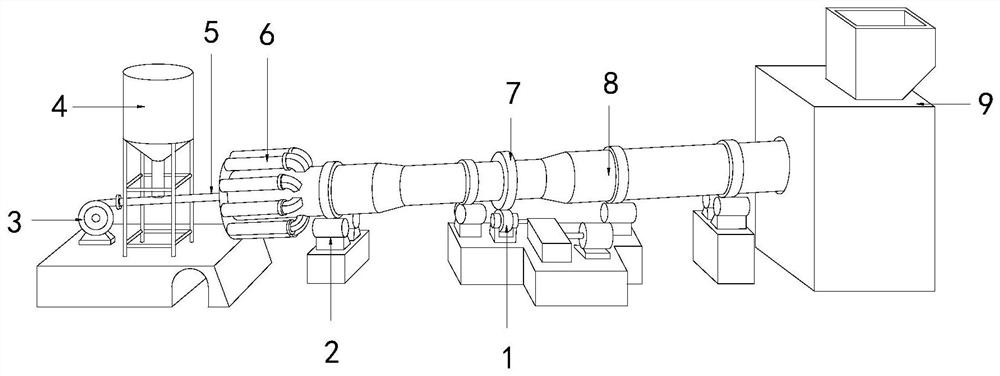

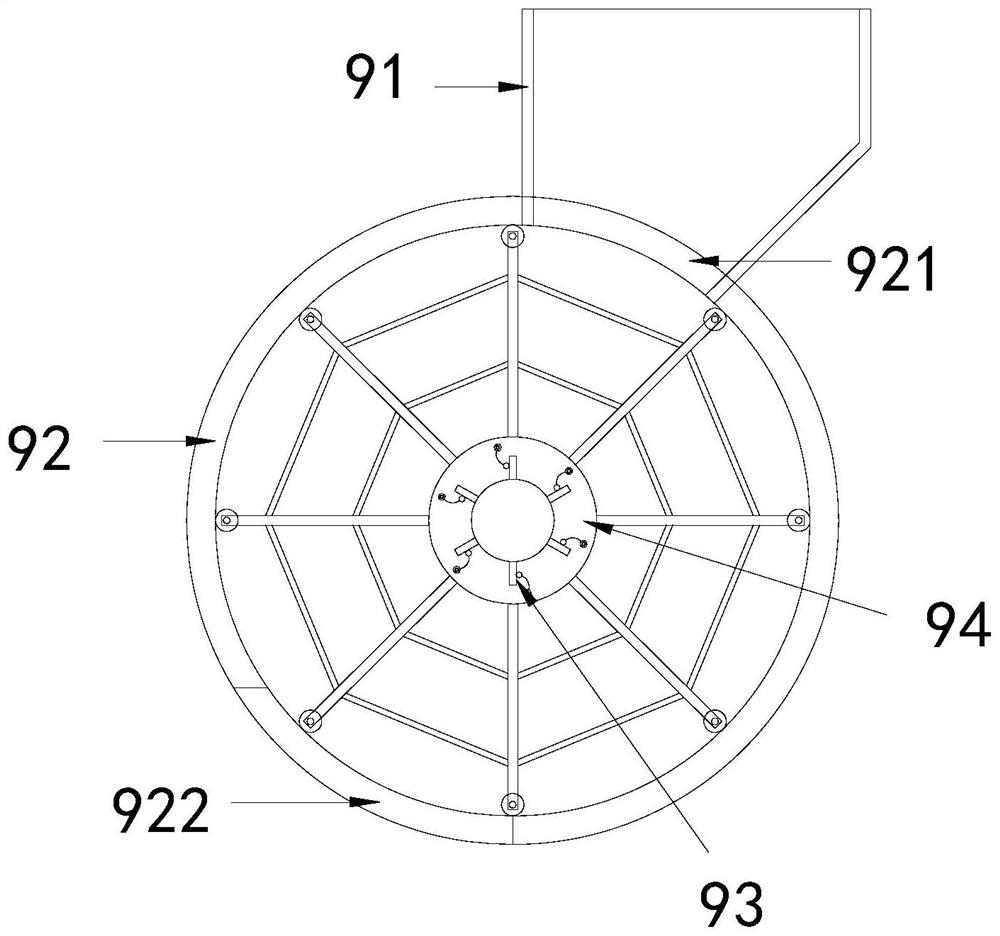

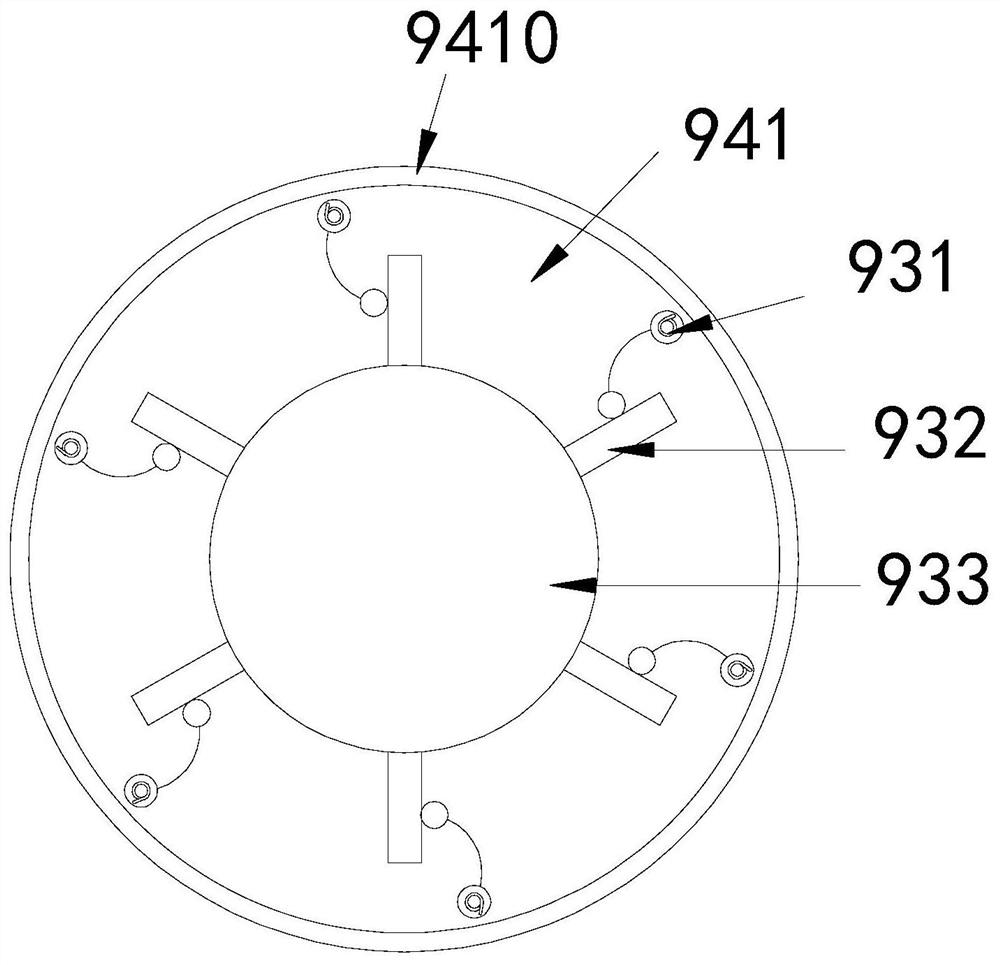

[0028] see Figure 1-5 , the present invention provides a metallurgical equipment technical solution that is convenient for transportation: its structure includes a power unit 1, a supporting wheel 2, a blower 3, a pulverized coal bin 4, a coal injection pipe 5, a cooling cylinder 6, a gear 7, a kiln body 8, a The feeder 9, the gear 7 is wrapped in the middle of the kiln body 8, the gear 7 is connected with the power device 1 at the bottom, the two ends of the kiln body 8 are respectively set on the supporting rollers 2, and the kiln body 8 is inclined, the inlet end of the kiln body 8 is connected to the feeder 9, the outlet end of the kiln body 8 is connected to the blower 3 through the coal injection pipe 5, and the middle of the coal injection pipe 5 is connected to the pulverized coal bin 4 The bottom is connected, and the outlet end of the kiln body 8 is connected with a cooling cylinder 6. The feeder 9 includes a hopper 91, a housing 92, a deceleration structure 93, and...

Embodiment 2

[0031] see Figure 1-6 , the present invention provides a metallurgical equipment technical solution that is convenient for transportation: its structure includes a power unit 1, a supporting wheel 2, a blower 3, a pulverized coal bin 4, a coal injection pipe 5, a cooling cylinder 6, a gear 7, a kiln body 8, a The feeder 9, the gear 7 is wrapped in the middle of the kiln body 8, the gear 7 is connected with the power device 1 at the bottom, the two ends of the kiln body 8 are respectively set on the supporting rollers 2, and the kiln body 8 is inclined, the inlet end of the kiln body 8 is connected to the feeder 9, the outlet end of the kiln body 8 is connected to the blower 3 through the coal injection pipe 5, and the middle of the coal injection pipe 5 is connected to the pulverized coal bin 4 The bottom is connected, and the outlet end of the kiln body 8 is connected with a cooling cylinder 6. The feeder 9 includes a hopper 91, a housing 92, a deceleration structure 93, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com