Flexible joint controlled in mixing mode

A flexible joint and hybrid control technology, applied in the field of robotics, can solve the problems of no limit device, high cost, and complicated design of flexible joints, and achieve the effect of protecting torsion springs and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

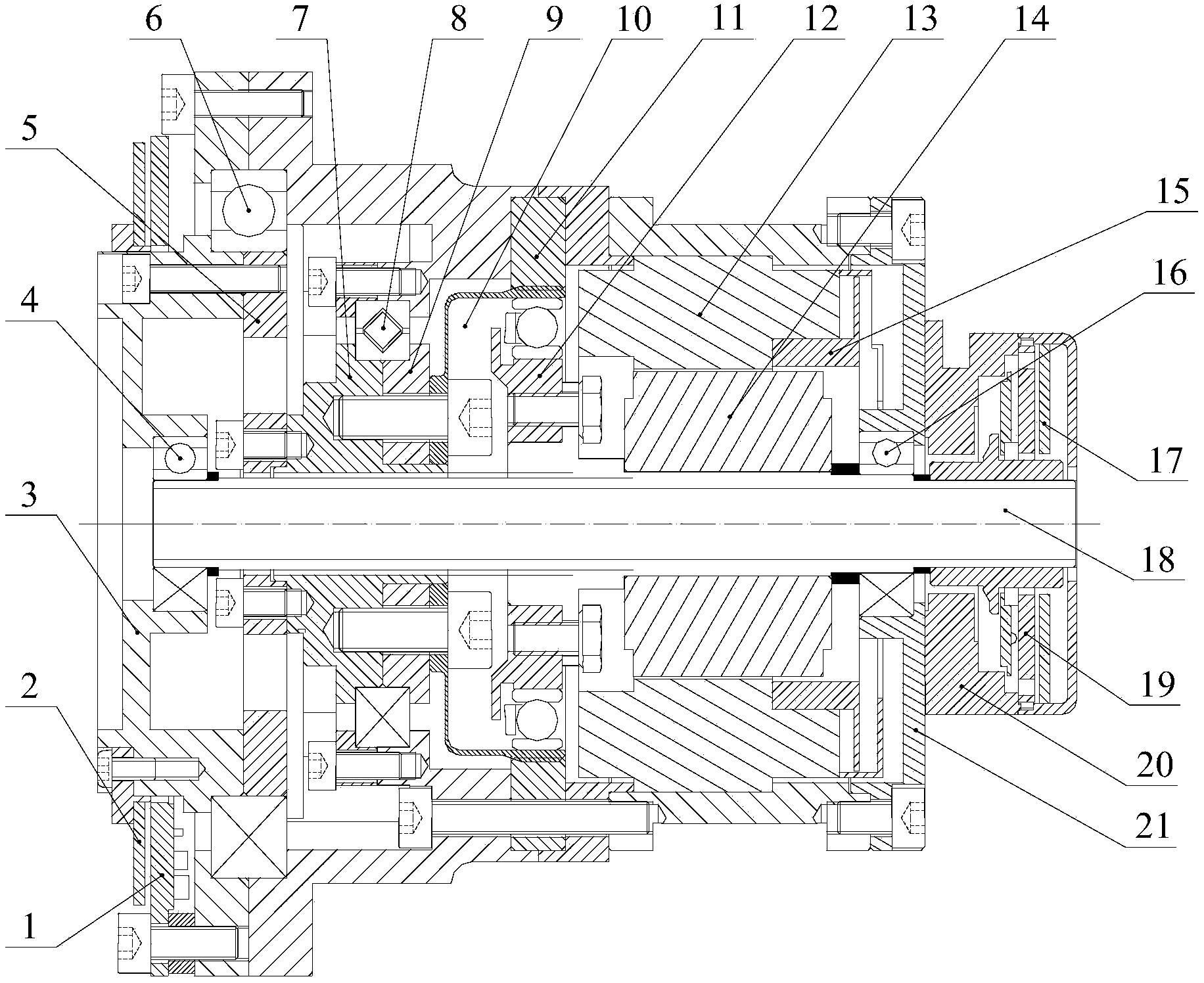

[0036] Such as figure 1 , 2 As shown, a flexible joint with hybrid control, including:

[0037] Motors with harmonic drive reducers;

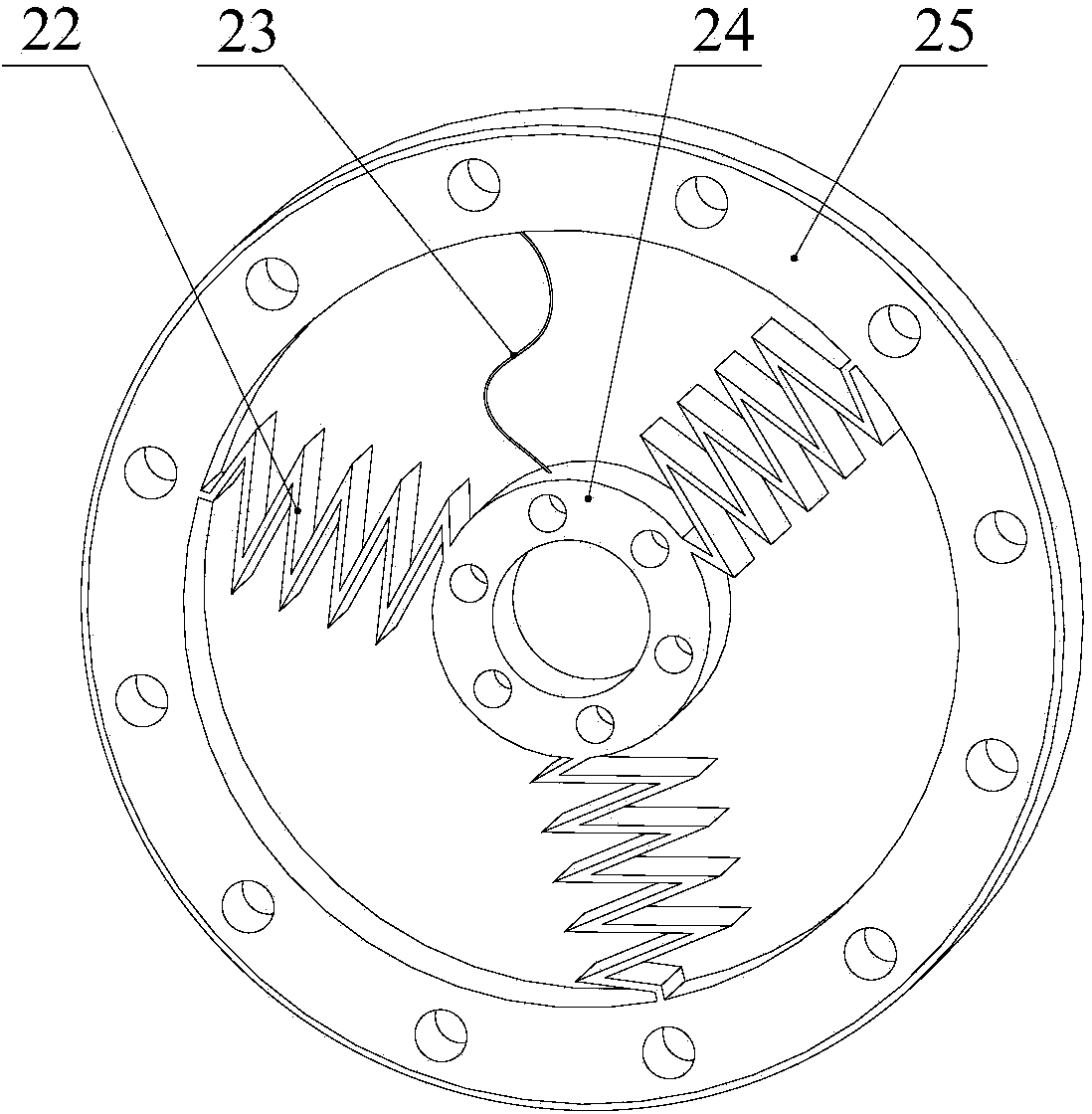

[0038] A torsion spring 5 connected to the output shaft 7 of the harmonic drive reducer;

[0039] A rotary mechanism driven by torsion spring 5;

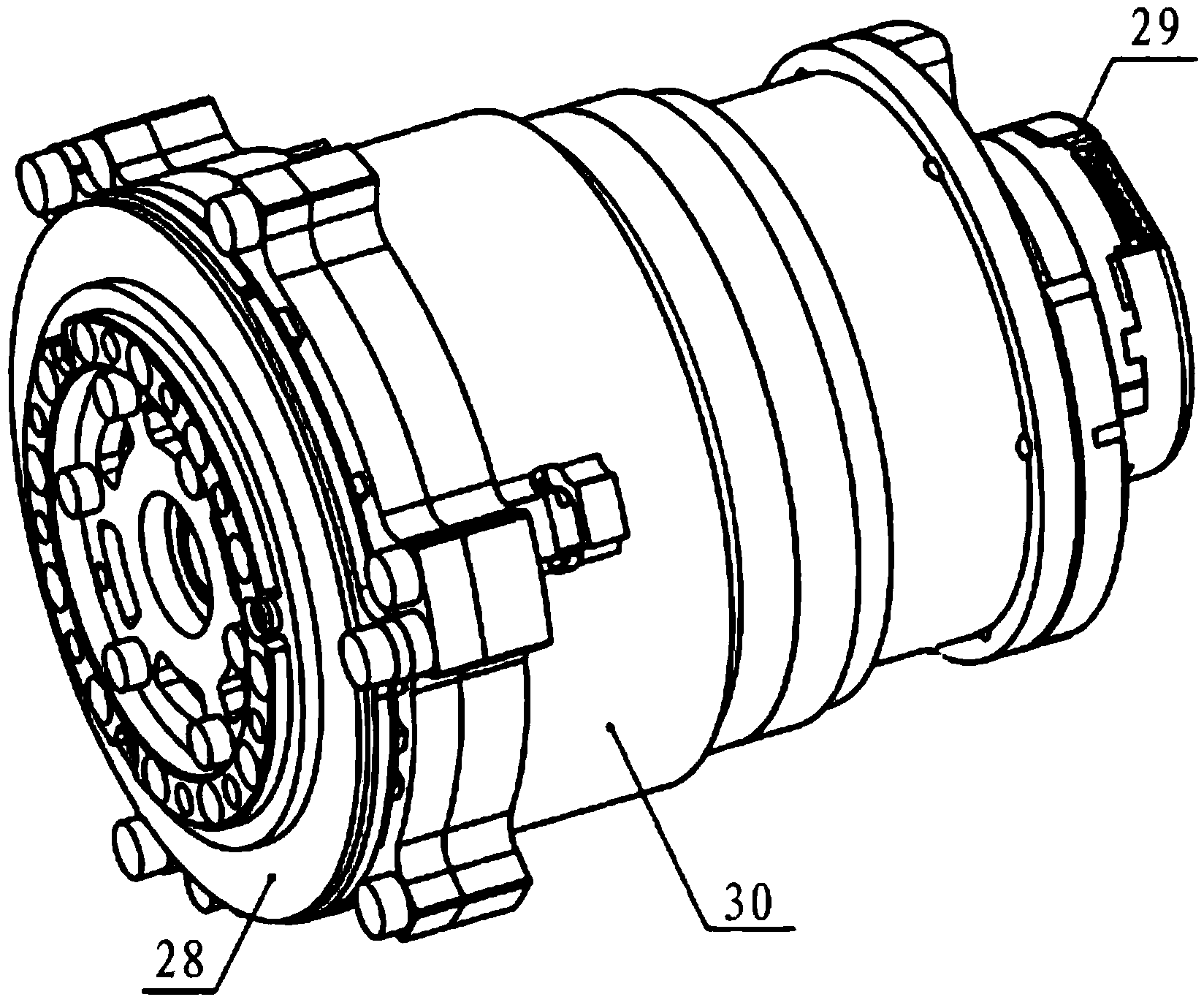

[0040] The measuring mechanism is composed of a motor encoder 29 for measuring the rotation angle of the motor shaft 18 and an absolute angle sensor 28 for measuring the rotation angle of the rotating mechanism.

[0041] The motor includes a motor shaft 18 , a motor housing 30 , a motor rotor 14 mounted on the motor shaft, and a motor stator 13 cooperating with the motor rotor, and a Hall sensor 15 is installed on the motor stator 13 . The motor shaft 18 is coaxial with the motor casing 30 through the second bearing 16 in the end cover 21 and the first bearing 4 in the transmission disc 3 .

[0042] The harmonic drive reducer includes a wave generator 12 , a rigid spline 11 fixed to the motor ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com