Bidirectional conjugate tooth profile design method for harmonic gear drive

A technology of conjugate tooth shape and design method, which is applied in the direction of components with teeth, belts/chains/gears, mechanical equipment, etc. Long time and other problems, to achieve the effect of increasing the conjugate contact area, increasing the range of the meshing area, and increasing the number of tooth pairs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

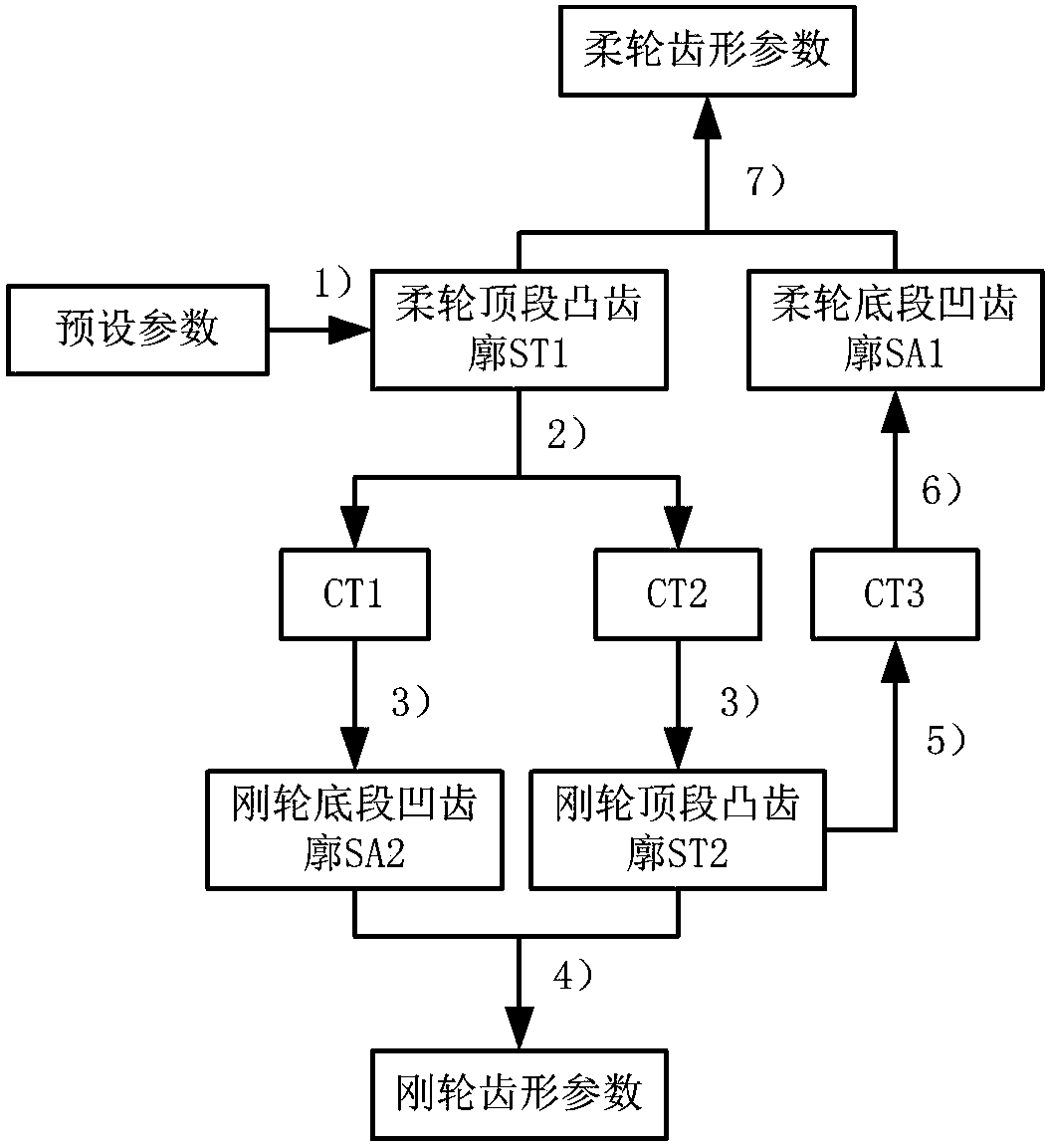

[0023] Taking the double-arc tooth shape design of harmonic gear transmission as an example, refer to figure 1 , a bidirectional conjugate tooth profile design method for harmonic gear transmission, comprising the following steps:

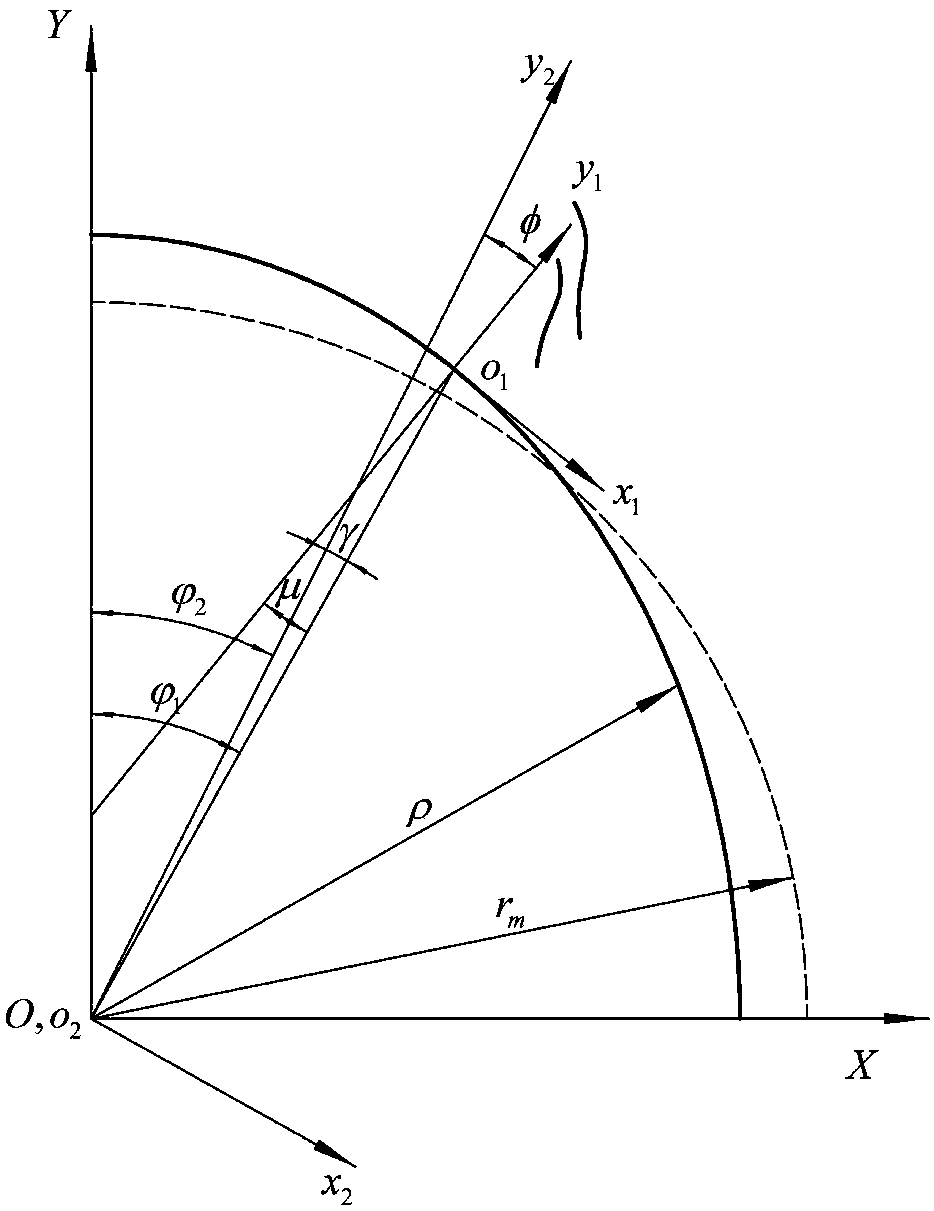

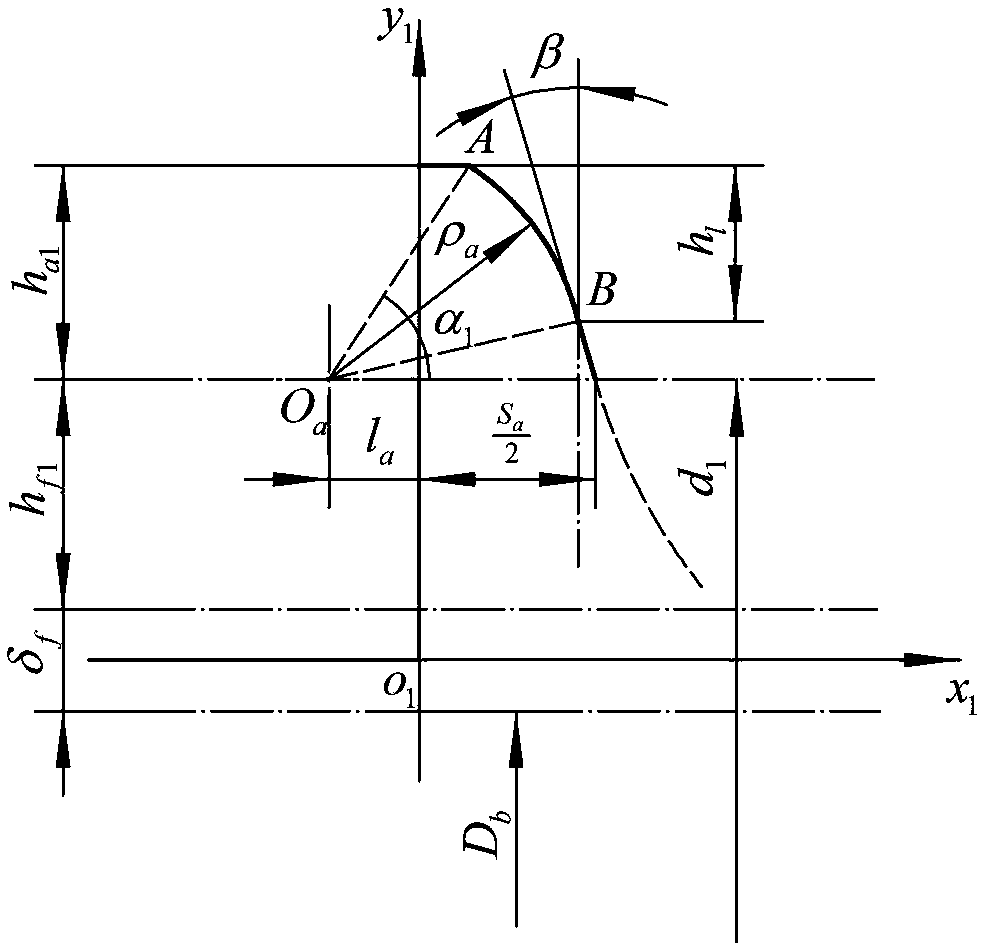

[0024] 1) First complete the design of the structural parameters according to the load and other requirements, and then determine the meshing parameters of the tooth shape to be designed; figure 2 As shown, first establish each coordinate system, establish the coordinate system {OXY} of the wave generator, the origin is located at the rotation center of the wave generator, the Y axis coincides with the long axis of the wave generator, and the X axis coincides with the short axis of the wave generator; establish the flexspline Gear tooth coordinate system {o 1 x 1 the y 1}, its y 1 The axis coincides with the center l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com