Two-stage cantilever type axial-flow expander

An expander, cantilever type technology, applied in the field of expanders, can solve the problems of complex system, high unit speed, large axial thrust of the expander, etc., and achieve the effect of simple control system, high mechanical efficiency and low working speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

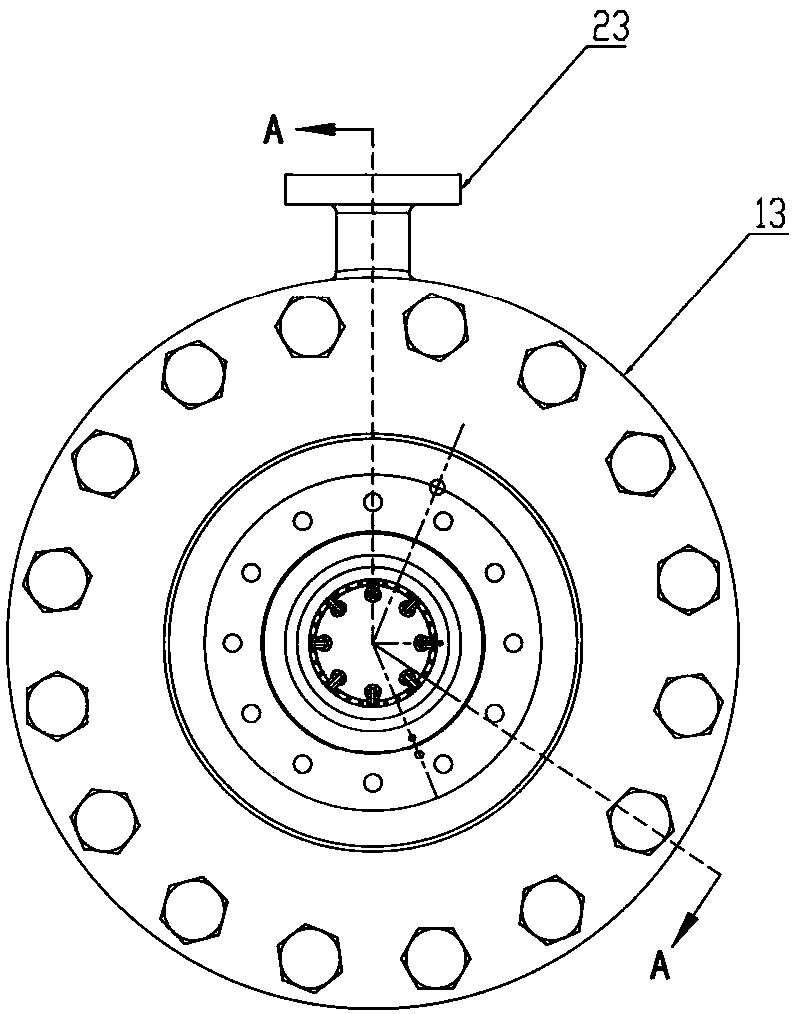

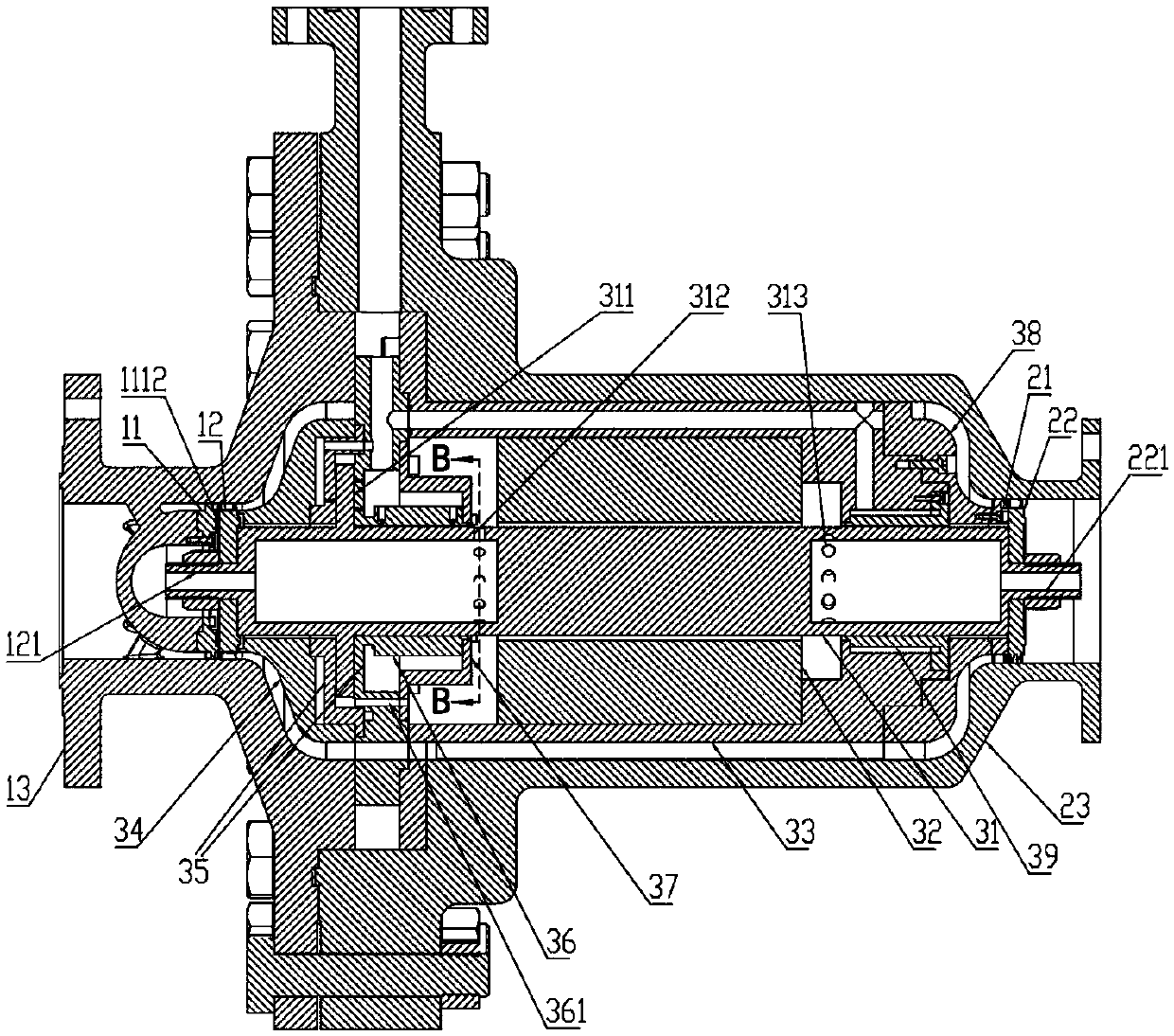

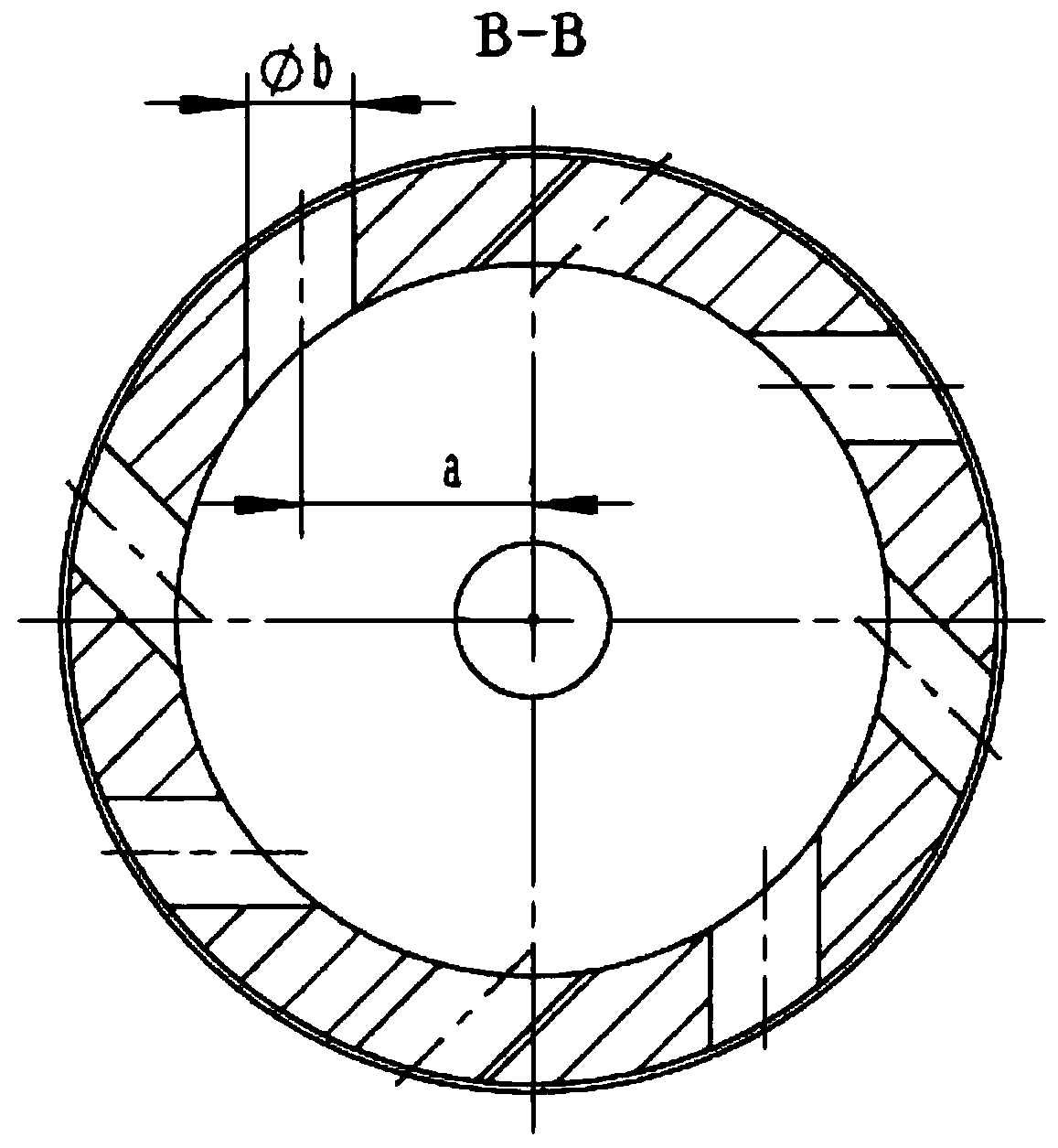

[0053] Such as figure 1 , figure 2 As shown, a two-stage cantilever type axial flow expander includes a first-stage expander, a second-stage expander, and a motor; the first-stage expander includes an intake housing 13, a first-stage nozzle ring 11 and The first-stage rotor impeller 12; the second expander includes the unit outer shell 23, the second-stage nozzle ring 21 and the second-stage rotor impeller 22; the motor includes a motor rotor 31 and a stator winding 32; the air intake casing The body 13 is arranged opposite to the unit outer shell 23 to form a cavity, and the motor rotor 31 is arranged in the cavity along the axis of the cavity, and the outer direction of the motor rotor 31 is along the direction from the intake shell 13 to the unit outer shell 23. An auxiliary thrust bearing housing 34, a motor housing 33 and a second-stage guide housing 38 are provided. The end face of the motor rotor 31 close to the intake housing 13 is coaxially provided with a first-sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com