Electronic pump

An electronic pump and rotor technology, applied in the field of centrifugal pumps, can solve the problems of reducing component life, energy loss, large friction, etc., and achieve the effect of reducing friction loss and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

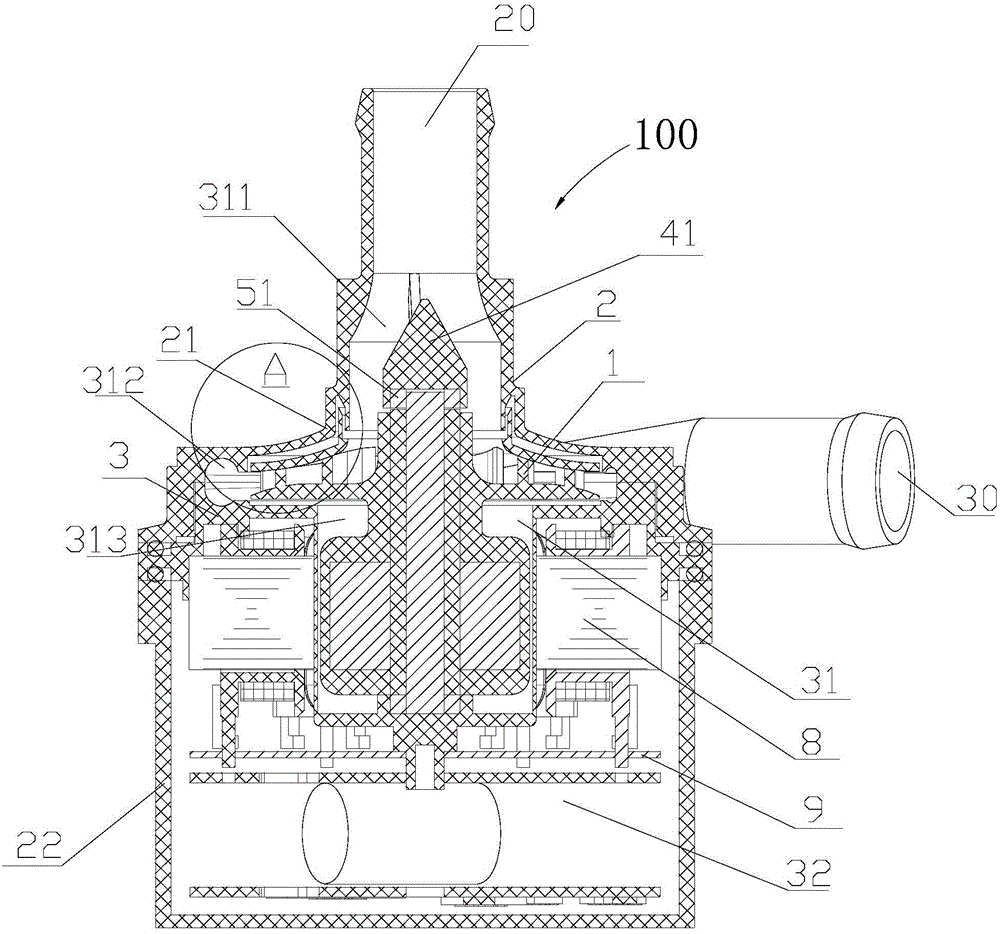

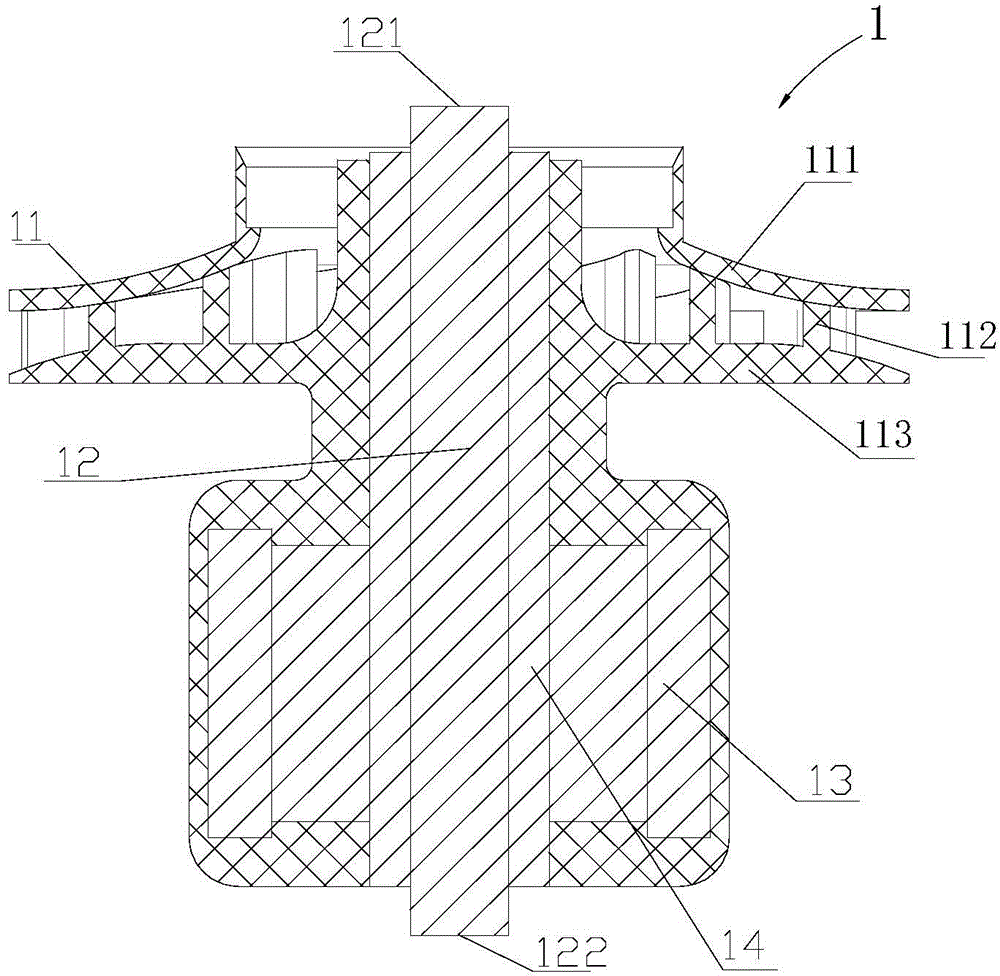

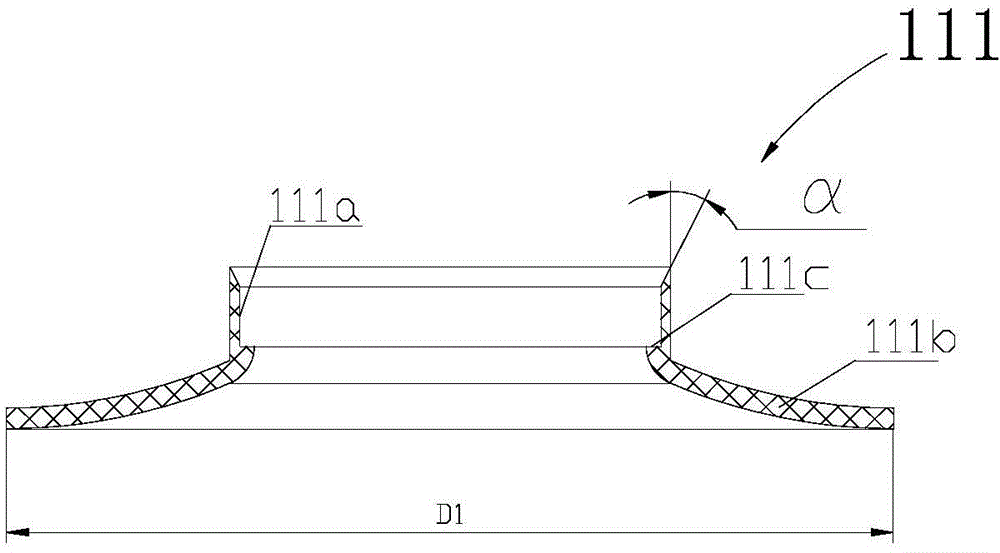

[0030] Such as Figure 1 to Figure 12 As shown, the electronic pump 100, 200, 300, 400 includes a rotor part 1, an outer casing 2, a separation sleeve 3, a stator part 8, and a circuit board 9; the outer casing 2 includes a first casing 21 and a second casing 22, and the rotor The component 1 includes a pump shaft 12, an impeller 11 and a rotor 13; the first housing 21 and the second housing 22 form the inner cavity of the electronic pump 100, and the separation sleeve 3 divides the inner cavity of the electronic pump 100 into two independent cavities, The two independent chambers are respectively: a wet chamber 31 for the circulation of the working medium and a dry chamber 32 where the working medium does not enter; the wet chamber 31 is formed by sealing between the first housing 21 and the separation sleeve 3, and the second housing 22 The dry ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com