Center knife rear type shield machine cutter head

A center knife and rear-mounted technology, which is applied in mining equipment, earthwork drilling, tunnels, etc., can solve the problems of limited excavation speed, large axial thrust, and reduced water content, so as to reduce axial thrust consumption and reduce axial thrust. thrust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The structure of the present invention will be further described below in conjunction with the accompanying drawings and through specific embodiments. It should be noted that this embodiment is descriptive and does not limit the protection content of the present invention.

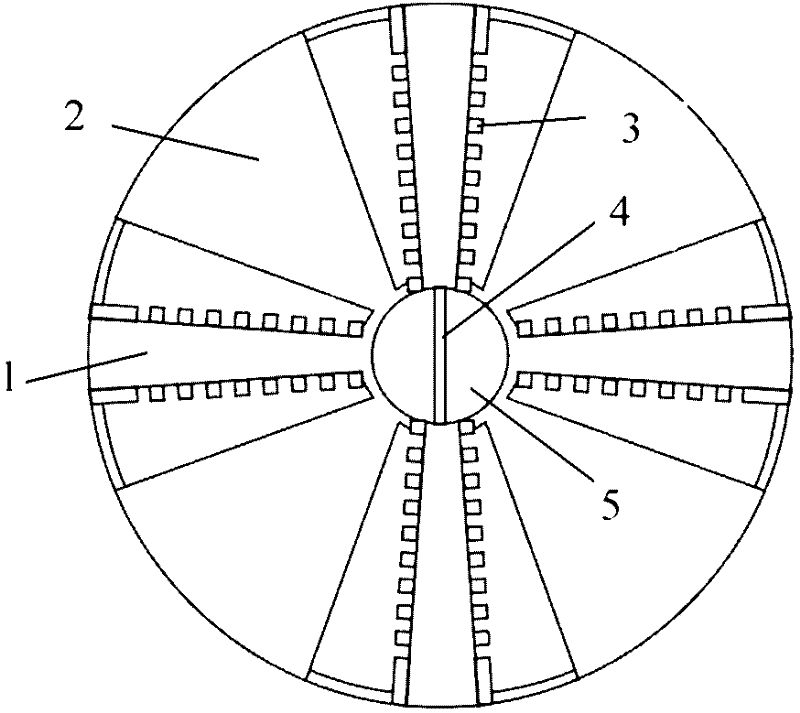

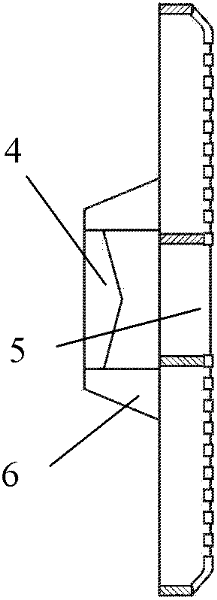

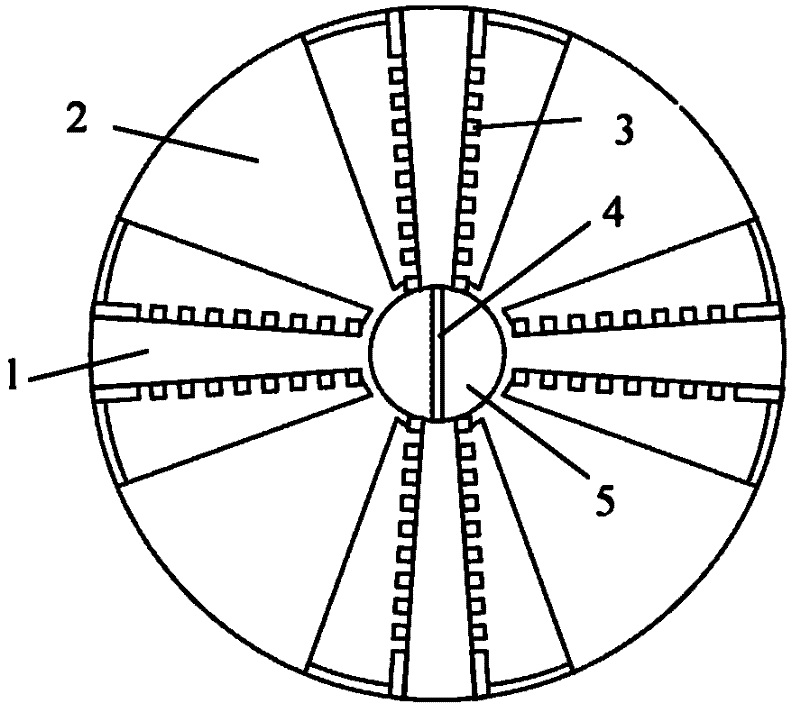

[0010] The cutter head of the shield machine with the center knife behind, including the knife beam 1, the width plate 2, the common excavation knife 3 and the center knife 4, etc., its structure is that there is a round hole 5 penetrating the cutter head in the center of the cutter head, and the center knife 4 is fixed behind the round hole of the cutterhead by the knife rest 6. The minimum distance between the cutting edge of the center knife 4 and the rear end face of the circular hole 5 is not less than half of the radius of the circular hole 5 . This kind of cutter head changes the stress state when the center cutter corresponds to the soil body being excavated, thereby greatly reducing the ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com