Centrifugal compressor for heavy oil hydrogenation device

A centrifugal compressor, heavy oil hydrogenation technology, applied in the components of pumping devices for elastic fluids, mechanical equipment, machines/engines, etc., can solve problems such as no reference value and technical inspiration, and reduce axial Thrust, smooth running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

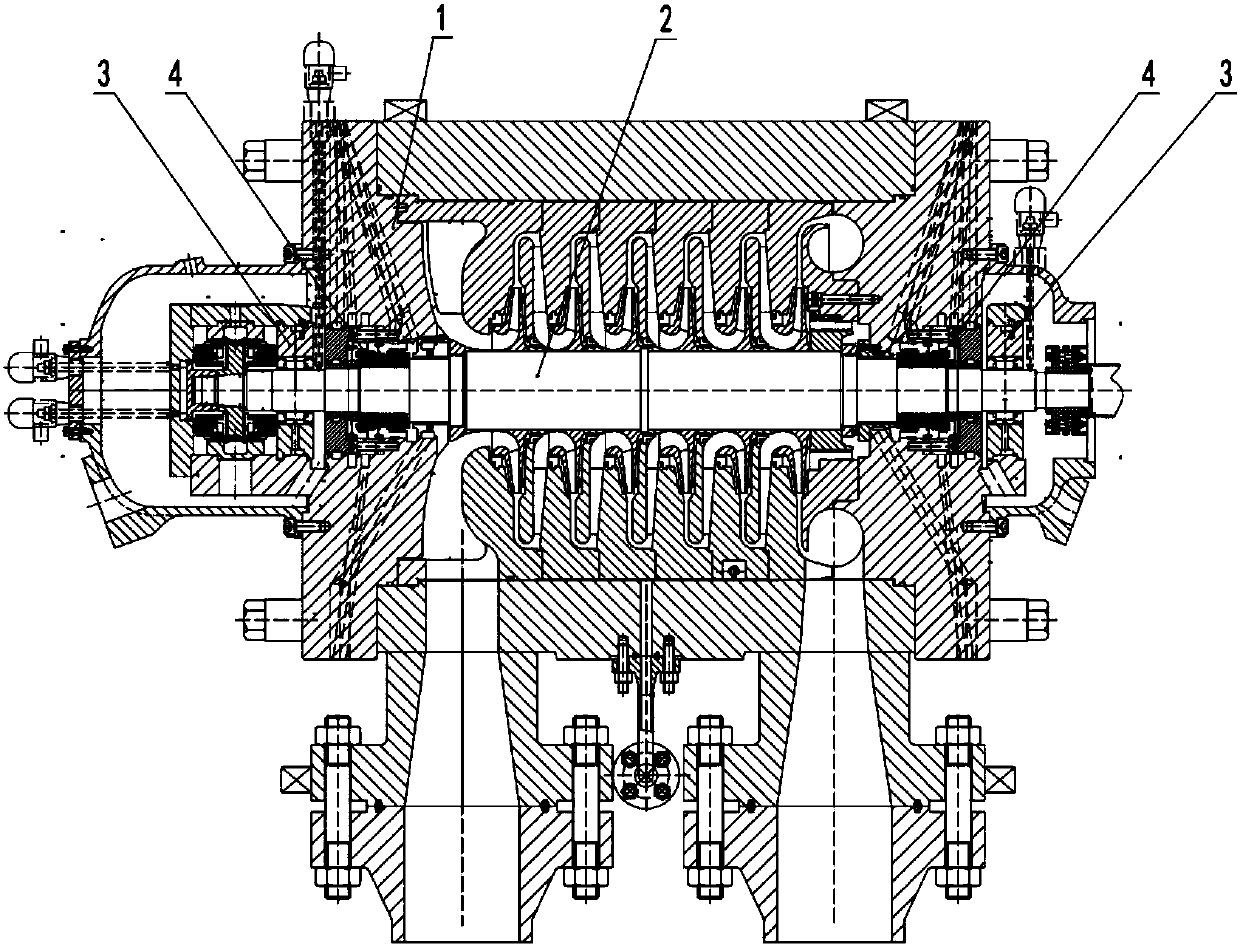

[0027] Example 1 Circulating hydrogen compressor for residual oil hydro-upgrading unit

[0028] This embodiment 1 is a circulating hydrogen compressor for a residual oil hydrogenation upgrading device, which is a kind of heavy oil hydrogenation device, and this set of devices can effectively utilize the remaining substances after purifying light oil in petrochemical plants , After hydrotreating, heavy oil can be converted into light oil and middle distillate, forming a relatively clean energy source. The structure of the circulating hydrogen compressor used in residual oil hydrogenation is a vertical split structure, and the general operating pressure can reach 15-20Mpa, and the pressure of some devices can exceed 20Mpa. Six-stage centrifugal compressor, the impeller adopts a binary closed impeller, and its blade adopts a backward curved structure; the diffuser adopts a vaneless diffuser.

Embodiment 2

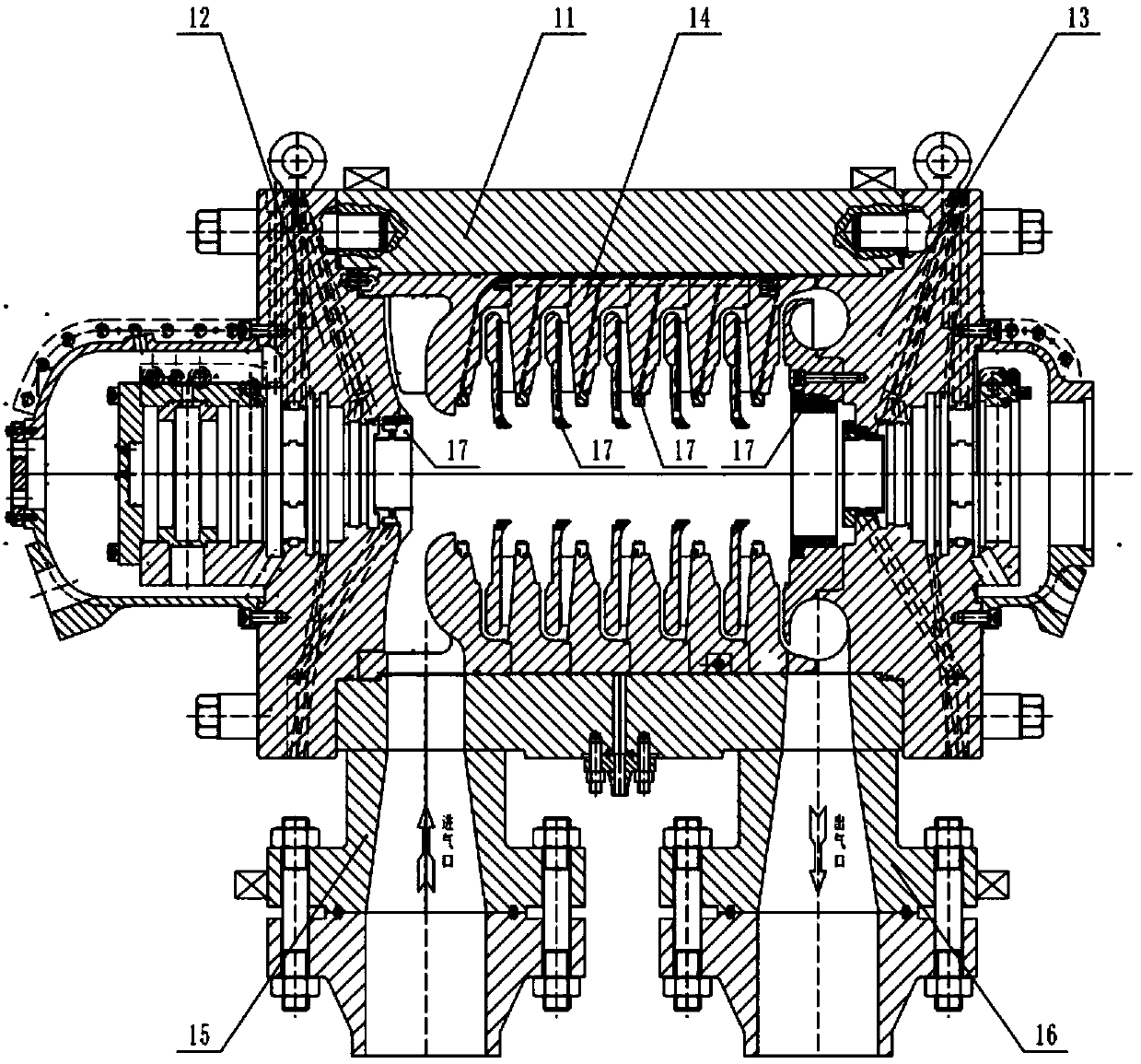

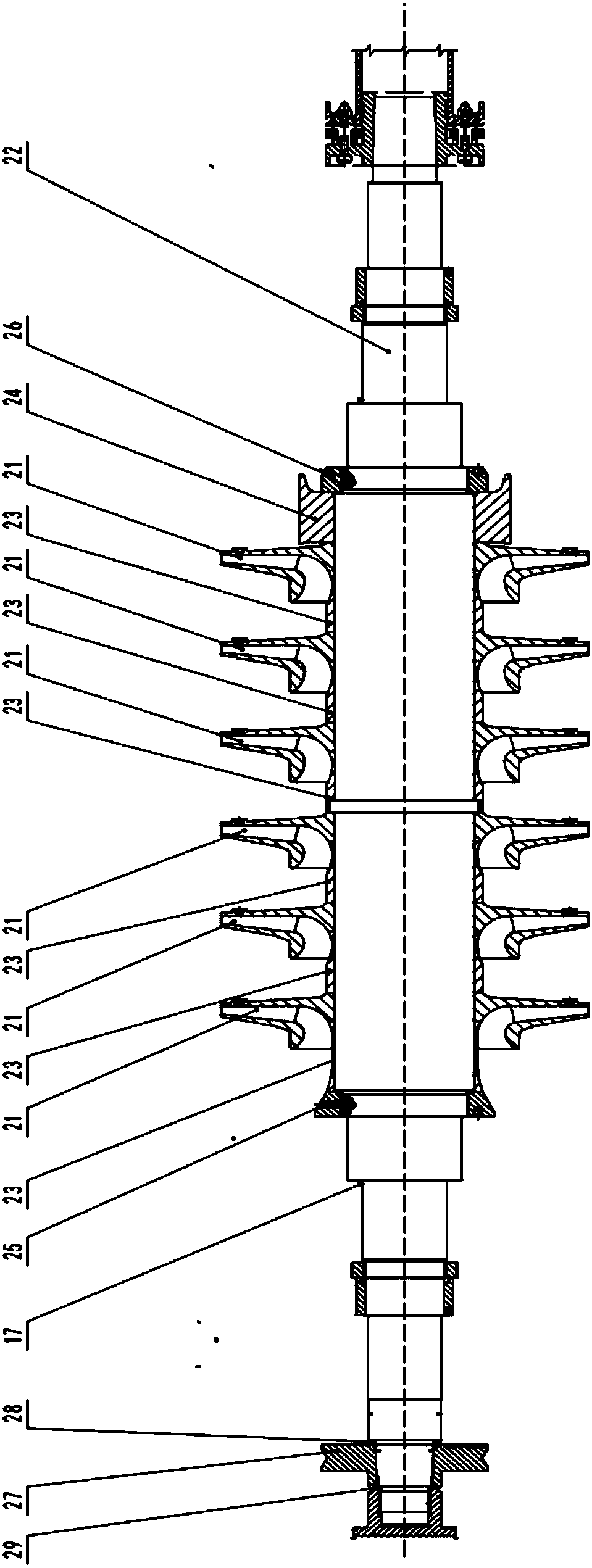

[0029] Example 2 Circulating hydrogen compressor for wax oil hydro-upgrading unit

[0030] This embodiment 2 is a circulating hydrogen compressor for a wax oil hydrotreating and upgrading unit, which is also a kind of heavy oil hydrogenation unit. This set of equipment can effectively utilize the remaining oil after purifying light oil in petrochemical plants After hydrotreating, heavy oil can be converted into light oil and middle distillate, forming a cleaner energy source. The structure of the circulating hydrogen compressor used in the hydrogenation of wax oil is a vertical split structure, and the general operating pressure can reach 15-20Mpa. Eight-stage centrifugal compressor, the impeller adopts a closed impeller, the impeller adopts a binary structure, and its blades adopt a backward curved structure, and the blades of the front and rear impellers are deflected by 15 degrees; a bladeless diffuser is used.

Embodiment 3

[0031] Embodiment 3 Circulating hydrogen compressor for naphtha hydro-upgrading unit

[0032] Example 3 is a circulating hydrogen compressor for a naphtha hydro-upgrading device, which is also a kind of heavy oil hydrogenation device. This device can effectively utilize the naphtha produced by a petrochemical plant, and undergo hydrogenation treatment It can convert naphtha into light oil and middle distillate to form a relatively clean energy source. The structure of the circulating hydrogen compressor used in naphtha hydrogenation is a vertical split structure, and the general operating pressure is less than 10Mpa, and the pressure will vary depending on the process. The corresponding parameters will also change. The number of impellers varies from 6 to 8, and the diameter of the impeller varies from 400mm to 800mm. The impeller still adopts a binary closed impeller, and its blades adopt a backward curved structure; The compressor uses a vaneless diffuser.

[0033] The abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com