Sealing in hydraulic turbine unit

A technology for turbines and sealing rings, which is applied to the sealing of engines, mechanical equipment, engine components, etc., and can solve problems such as inability to center

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

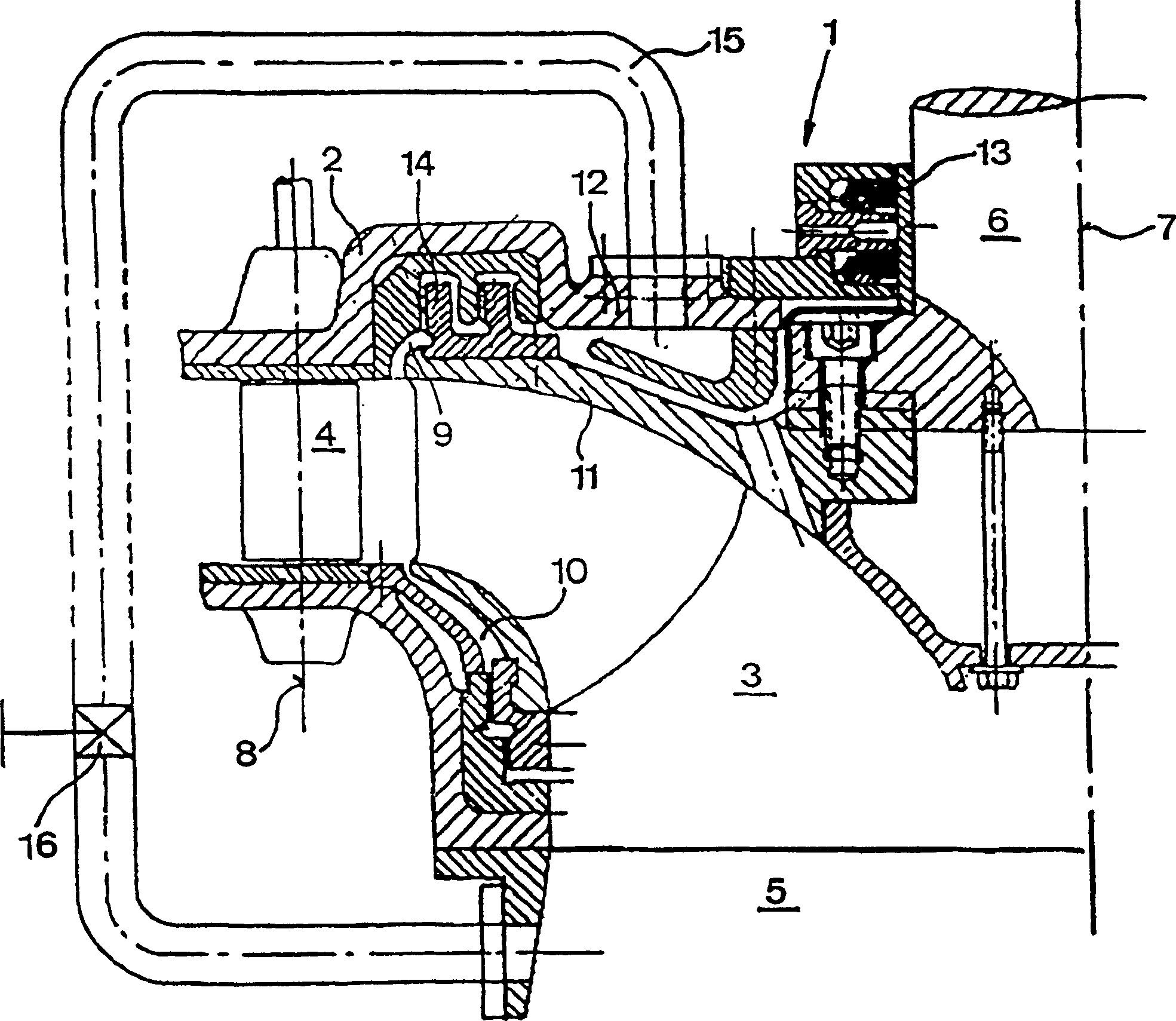

[0028] figure 1 A Francis turbine 1 according to the prior art as known from the book "Rabe, Hydraulische Maschinen und Anlagen" is shown schematically.

[0029] An impeller 3 rotates in a housing 2 through which water flows in via a guide wheel 4 or its separate blades which are rotatable but mounted in the housing 2 with a fixed shaft 8 . The impeller 3 comprises delivery channels extending in the circumferential direction and running curved relative to the turbine shaft 7 , so that the water leaves the impeller 3 approximately axially downwards into the suction pipe 5 .

[0030] Of course, there is an upper gap or gap 9 and a lower gap or gap 10 between the fixed housing 2 and the impeller 3 . The underseam leads to a loss of interstitial water, which flows into the area of the suction pipe without the energy it contains being able to do work, but other than this loss, there are no other problems.

[0031]This is in contrast to water flowing into the upper gap 9 between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com