Adjusting system for axial thrust of steam turbine under variable working conditions and using method of adjusting system

A technology of axial thrust and adjustment system, which is applied in the direction of mechanical equipment, engine components, machines/engines, etc., can solve problems such as complex variable working conditions, complex axial thrust changes of units, and excess force on thrust bearings, etc., to achieve Avoid the effect of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

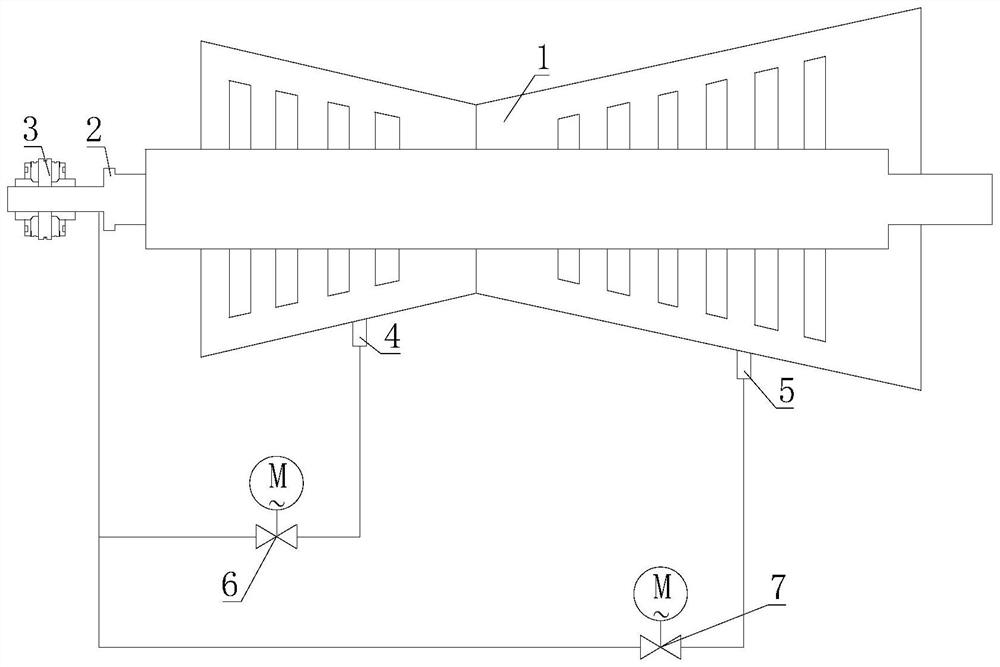

[0024] Such as figure 1 As shown, the axial thrust adjustment system of the steam turbine under variable working conditions in this embodiment includes a steam turbine 1, a balance disc 2 is installed on the rotor of the steam turbine 1, and a thrust bearing 3 is connected to the stator of the steam turbine 1; The first steam extraction port 4 and the second steam extraction port 5 are provided, the first steam extraction port 4 and the second steam extraction port 5 are respectively connected to the balance plate 2 through pipelines, the first steam extraction port 4 is connected to the steam inlet of the steam turbine 1 The distance between the ports is smaller than the distance between the second steam extraction port 5 and the steam inlet port of the steam turbine 1, and the first regulating valve 6 is connected to the pipeline between the first steam extraction port 4 and the balance plate 2, and the second steam extraction port 5 and the The pipeline between the balance ...

Embodiment 2

[0032] A method for using an axial thrust adjustment system under variable operating conditions of a steam turbine, comprising the following steps:

[0033] S1: Adjust the steam turbine 1 from the design working condition to the transitional working condition; wherein, the transitional working condition is 40% to 60% of the rated pure condensing or pure back working condition;

[0034] S2: Close the first regulating valve 6 and open the second regulating valve 7; wherein, the first regulating valve 6 is located on the pipeline between the first steam extraction port 4 and the balance plate 2, and the second regulating valve 7 is located on the second steam extraction port On the pipeline between the port 5 and the balance plate 2, the first steam extraction port 4 and the second steam extraction port 5 are respectively arranged on the steam turbine 1, and the distance between the first steam extraction port 4 and the steam inlet port of the steam turbine 1 is smaller than that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com