Centrifugal compressor for gasoline and diesel oil hydrogenating and upgrading device

A centrifugal compressor and hydrogenation upgrading technology, which is applied to components, mechanical equipment, machines/engines, etc. of pumping devices for elastic fluids, can solve problems such as no reference value and technical inspiration, and achieve reduction in shaft The effect of thrust and smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

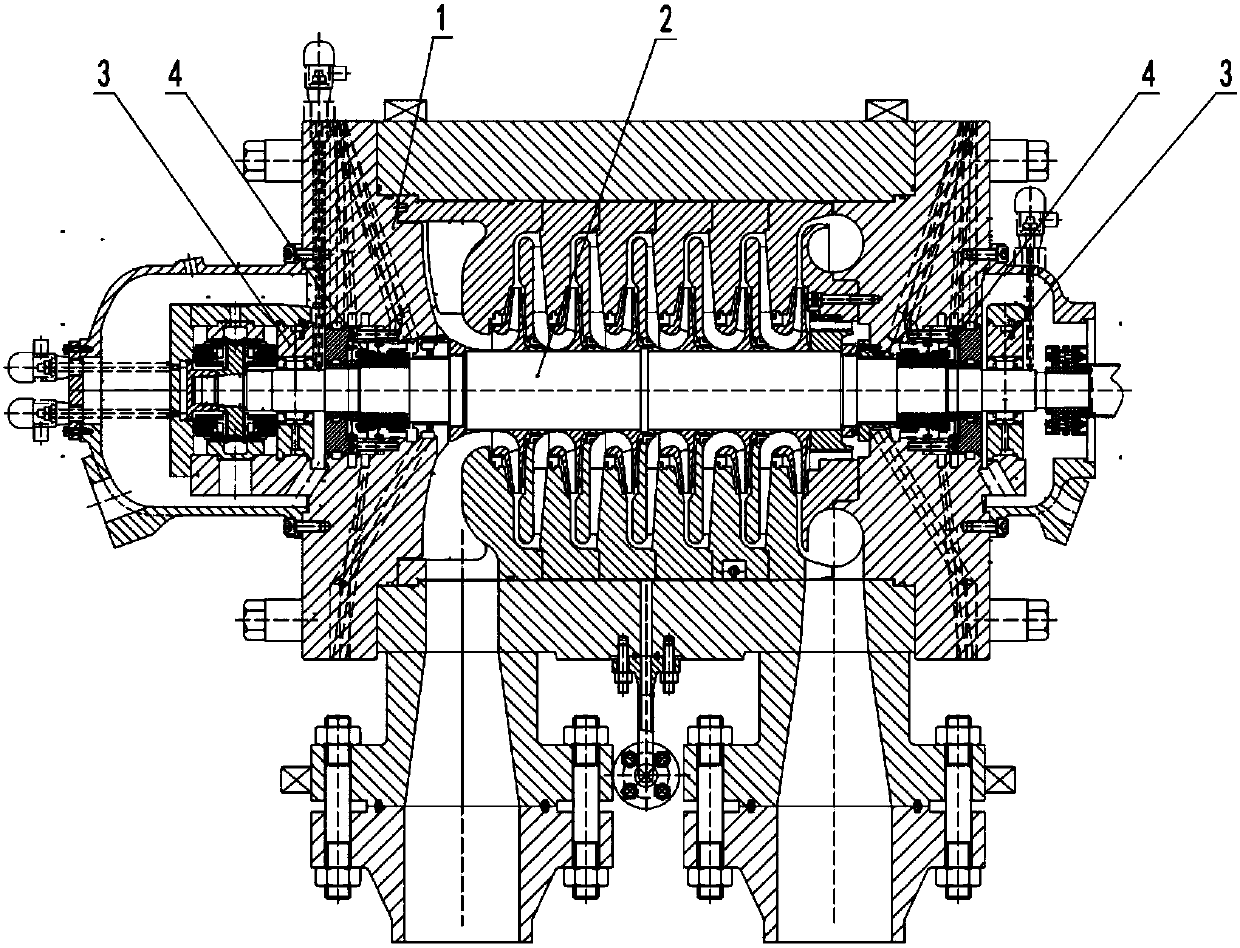

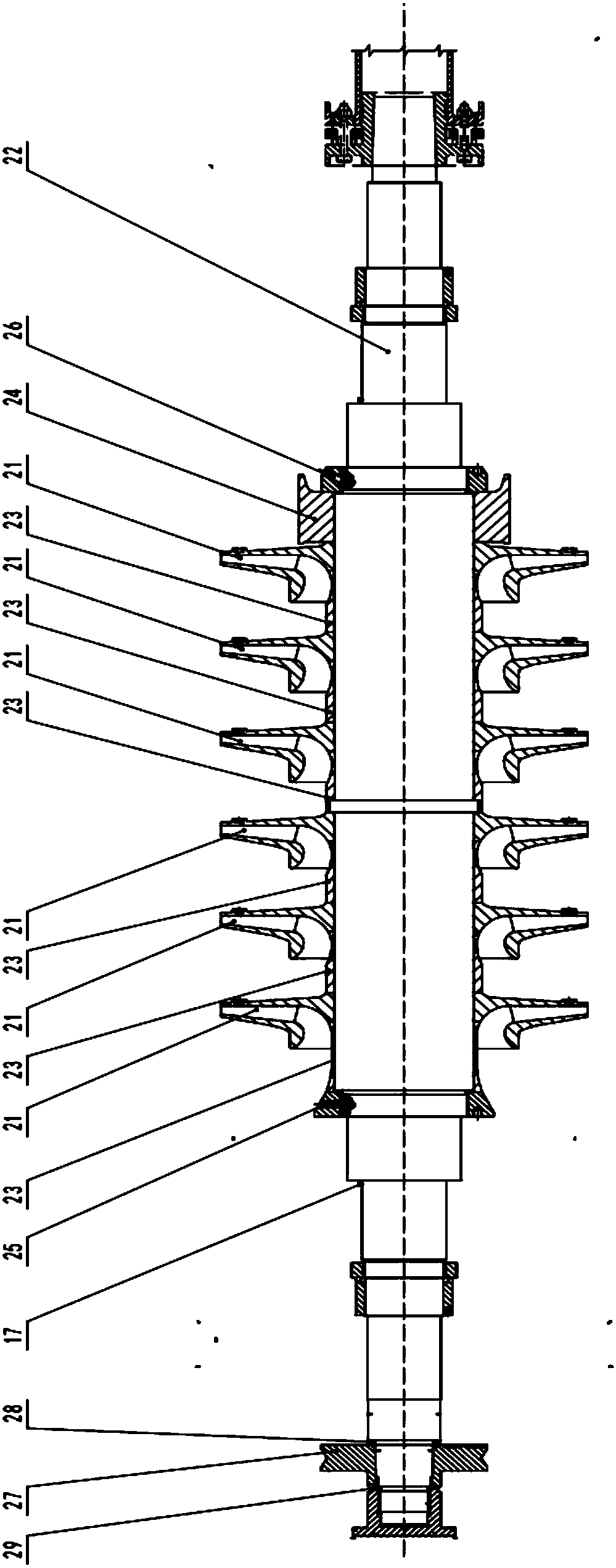

[0028] Example 1 Centrifugal compressor for gasoline hydrogenation upgrading device

[0029] This embodiment 1 is a six-stage centrifugal compressor with six impellers arranged in line. The impeller adopts a binary closed impeller with a diameter of 400 mm. Its blades adopt a backward curved structure; the diffuser adopts a vaneless diffuser. Steam conditions are available according to user site conditions, so this embodiment adopts steam turbine drive.

Embodiment 2

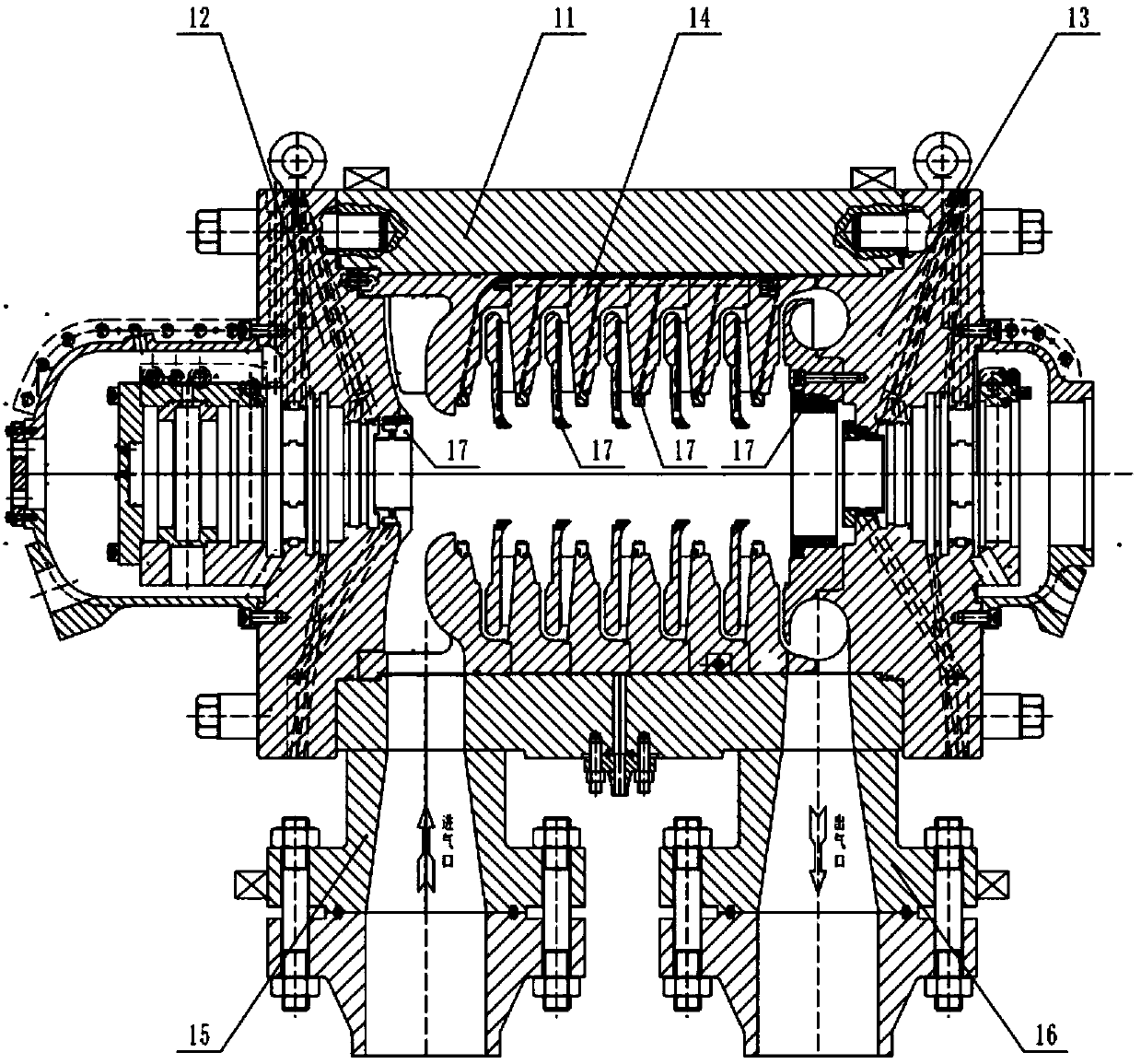

[0030] Example 2 Centrifugal compressor for gasoline hydrogenation upgrading device

[0031] This embodiment 2 is an eight-stage centrifugal compressor with eight impellers in line. The impeller adopts a binary closed impeller with a diameter of 400 mm. Its blades adopt a backward curved structure. The blades of the front and rear impellers deflect 15 degrees; adopt no blades Diffuser. In this embodiment, the user site does not have steam conditions, so the reforming device adopts the form of a motor, a gear box, and a compressor.

Embodiment 3

[0032] Example 3 Centrifugal compressor for diesel hydro-upgrading device

[0033] This embodiment 3 is a seven-stage centrifugal compressor with seven impellers arranged in line. The impeller adopts a binary closed impeller with a diameter of 400 mm. Its blades adopt a backward curved structure; the diffuser adopts a vaneless diffuser. Steam conditions are available according to user site conditions, so this embodiment adopts steam turbine drive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com