Hydraulic machine comprising a radial flow runner

一种水力机械、转轮的技术,应用在机械设备、水力发电、用于弹性流体的泵送装置的部件等方向,能够解决减小推力效果差等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

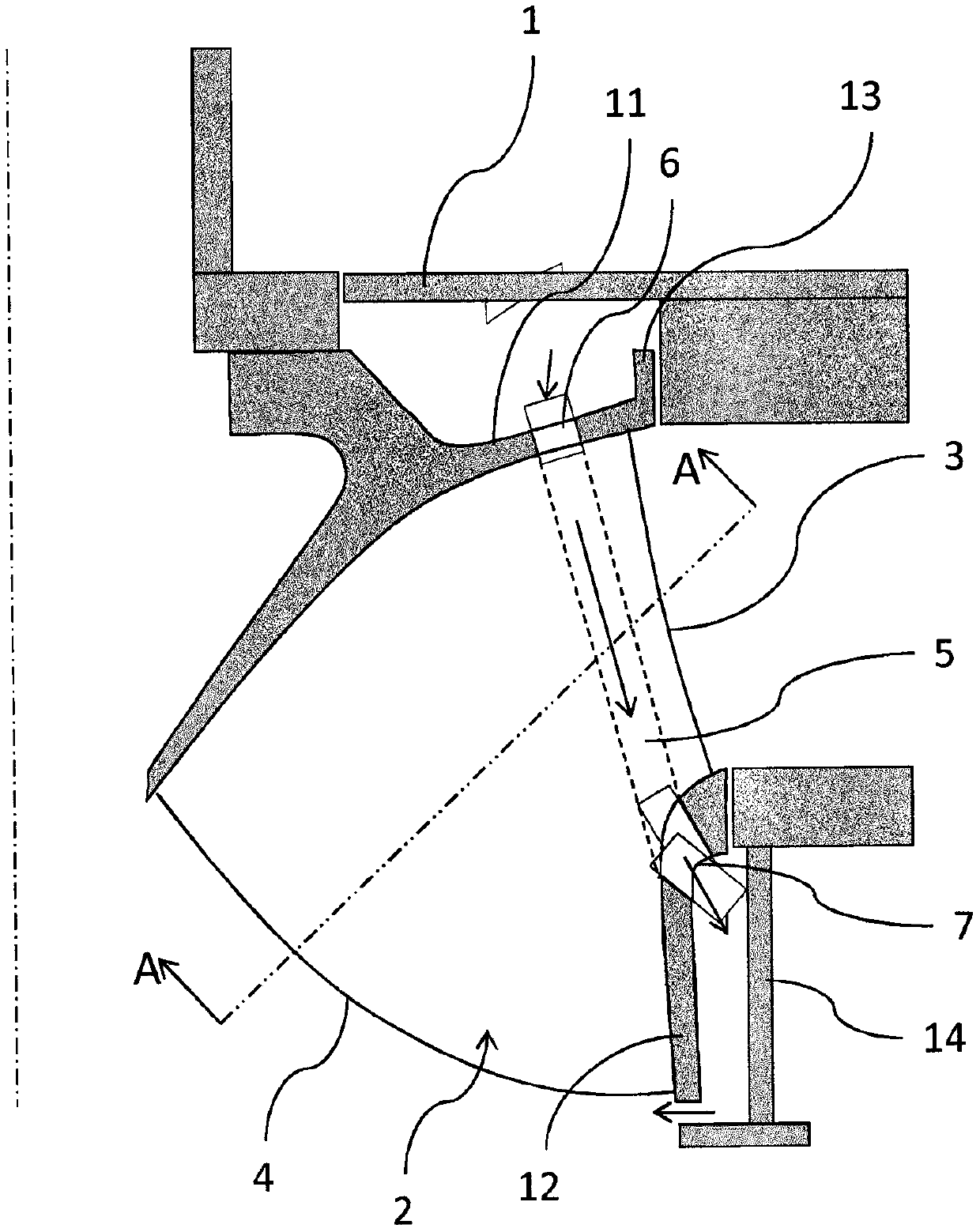

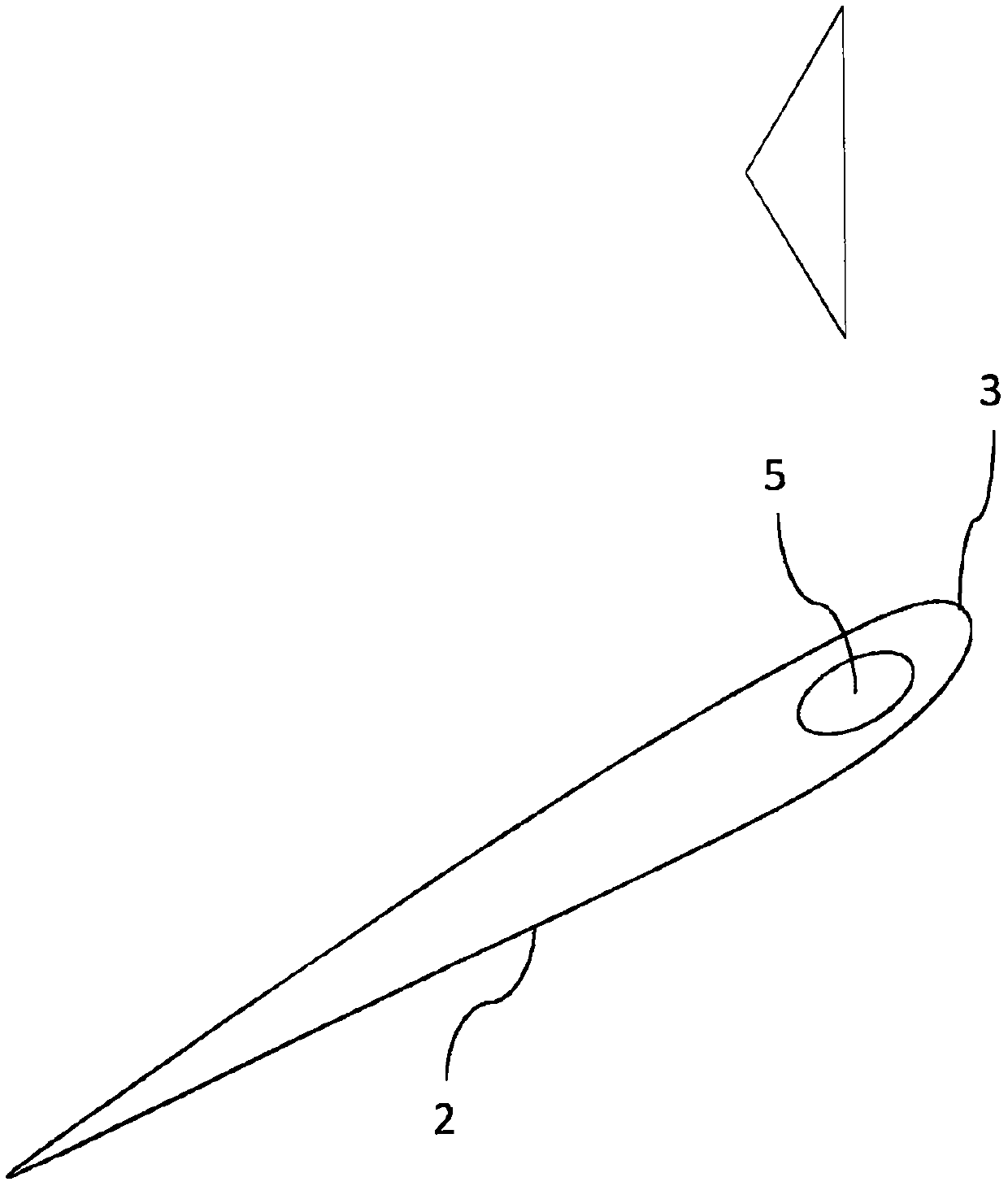

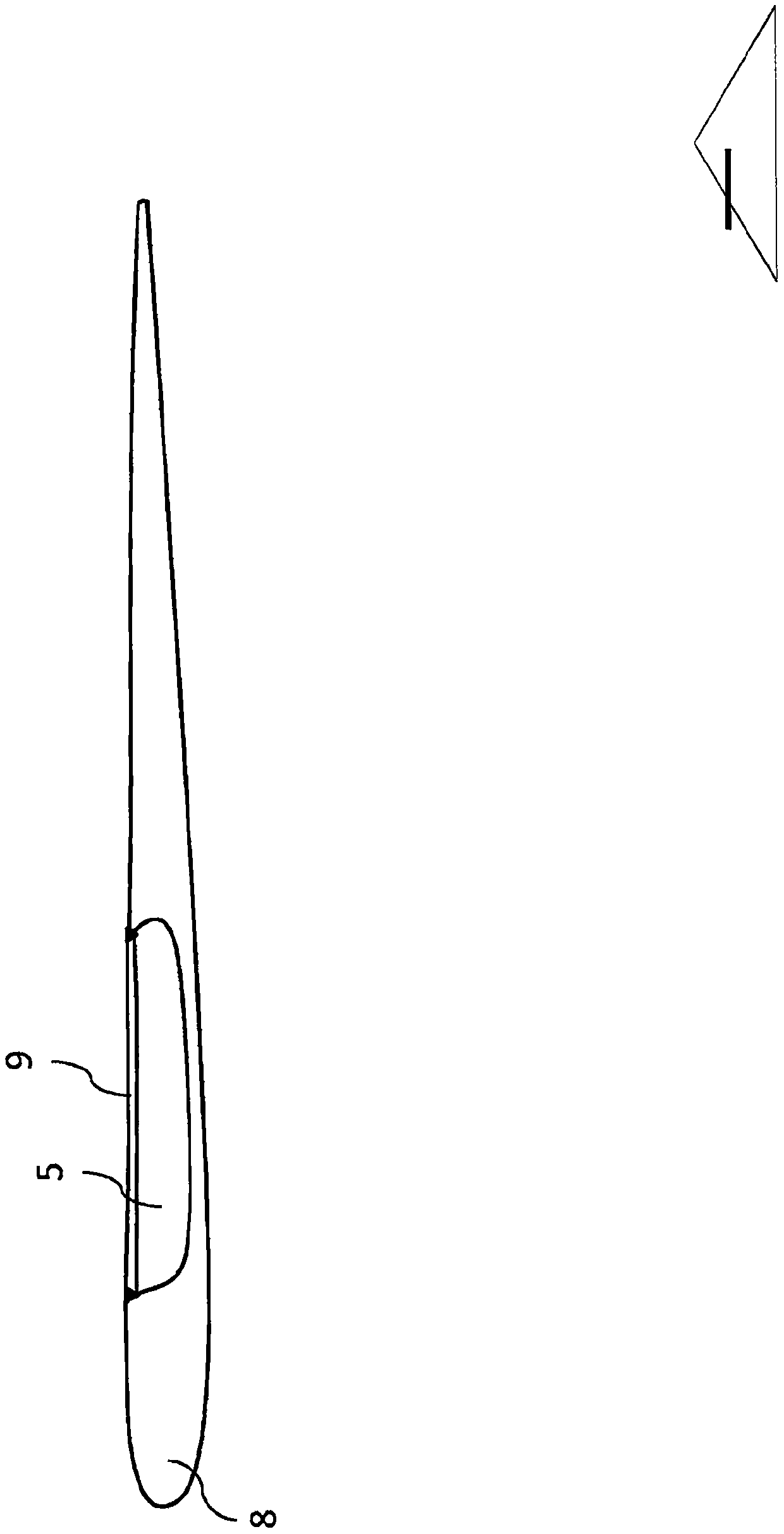

[0010] figure 1 A cross-sectional view of a hydraulic machine comprising a Francis-type runner according to the invention is schematically shown. The top cover is marked 1 and the bottom cover is marked 14 . The reel includes a reel crown, referenced 11 . The runner blades 2 extend between an upper crown 11 and a lower ring marked 12 . Blade 2 has two edges marked by 3 and 4 . Fluid entering the runner flows from edge 3 to edge 4 with the high pressure side adjoining edge 3 and the low pressure side adjoining edge 4 . Obviously, in pumping mode, the direction of fluid flow is reversed. The runner crown 11 comprises circumferentially positioned sealing means, referenced 13 . The sealing device 13 is explained as sealing the space between the top cover 1 and the upper crown 11 to prevent high-pressure water from entering. However, due to the imperfection of the seal, there will be a small amount of high-pressure water in the space above the upper crown 11 of the runner, re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com