Tangent pump for ship

A tangential pump, marine technology, applied in the directions of pumps, pump components, and components of pumping devices for elastic fluids, etc., can solve the problems of structural defects, reliability that does not meet the matching requirements of marine pressure water tanks, etc., and achieve a simple structure. , The effect of strong impact resistance and small axial thrust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

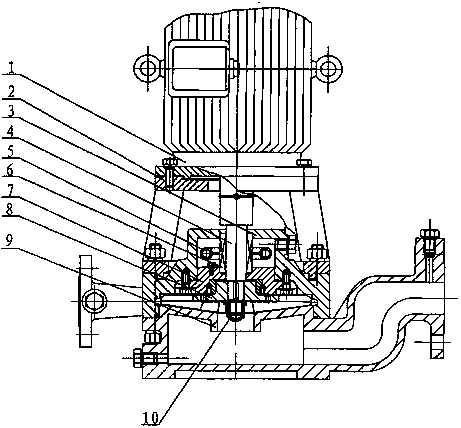

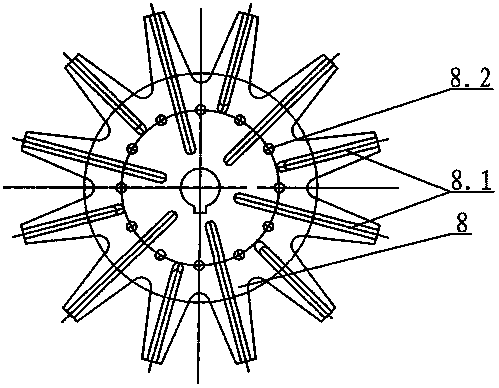

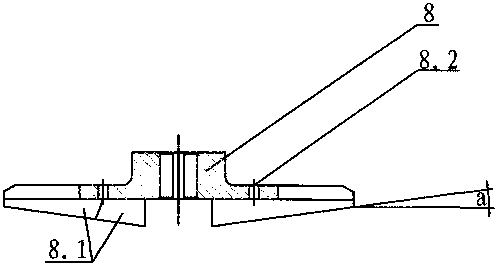

[0017] figure 1 The marine tangent pump shown is a vertical structure pump, which includes motor 1, bracket 2, pump body 3, pump shaft 4, seal expansion part 5, mechanical seal 6, gland 7, impeller 8, pump cover 9 and nut 10. The bracket 2 located in the middle section is a connecting piece of frame structure, its two ends are parallel to each other, the upper end is connected with the motor 1 , and the lower end is connected with the pump body 3 . The pump shaft 4 is fitted and connected with the output shaft end of the motor 1 , and the shaft section of the pump shaft 4 extending into the pump body 3 is fitted with a mechanical seal 6 and a seal expansion member 5 . The gland 7 cooperates with the pump body 3 to not only axially position the mechanical seal 6 but also form a sealing chamber for storing lubricating oil. The impeller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com