Ultrafine grinder

A technology of ultra-fine grinder and crushing chamber, which is applied in the direction of grain processing, etc., can solve problems such as the limitation of hammer knife speed, achieve the effects of reducing volume, prolonging service life, reducing mechanical vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

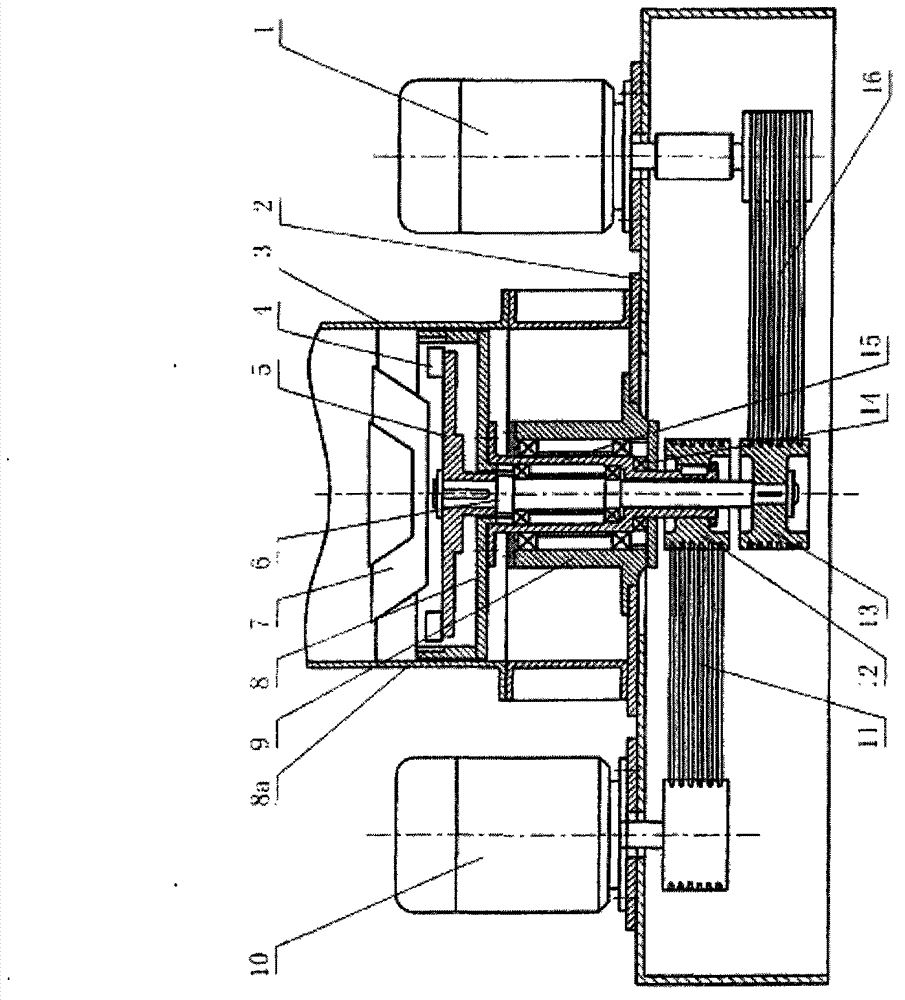

[0009] Such as figure 1 The shown ultrafine pulverizer comprises a frame 2, and a bearing seat 9 is provided on the frame 2, and an outer shaft 15 and a vertical shaft 6 that are set together and are rotatably connected to each other are arranged in the bearing seat 9. A crushing chamber 3 is provided, and a cylindrical ring gear 8 is arranged in the crushing chamber 3. The bottom of the ring gear 8 is closed, and the inner circumference of the ring gear 8 is provided with many raised tines 8a. The shape of the raised tines 83 is as follows: As shown in the figure, the vertical shaft 6 extends into the ring gear 8 from the center of the bottom of the ring gear 8, the upper end of the vertical shaft 6 is equipped with a hammer cutter disc 5, and a number of hammer cutters are installed on the periphery of the hammer cutter disc 5 corresponding to the protruding tines 4. The hammer cutter 4 is evenly spaced around the hammer cutter disc 5, and the crushing chamber 3 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com