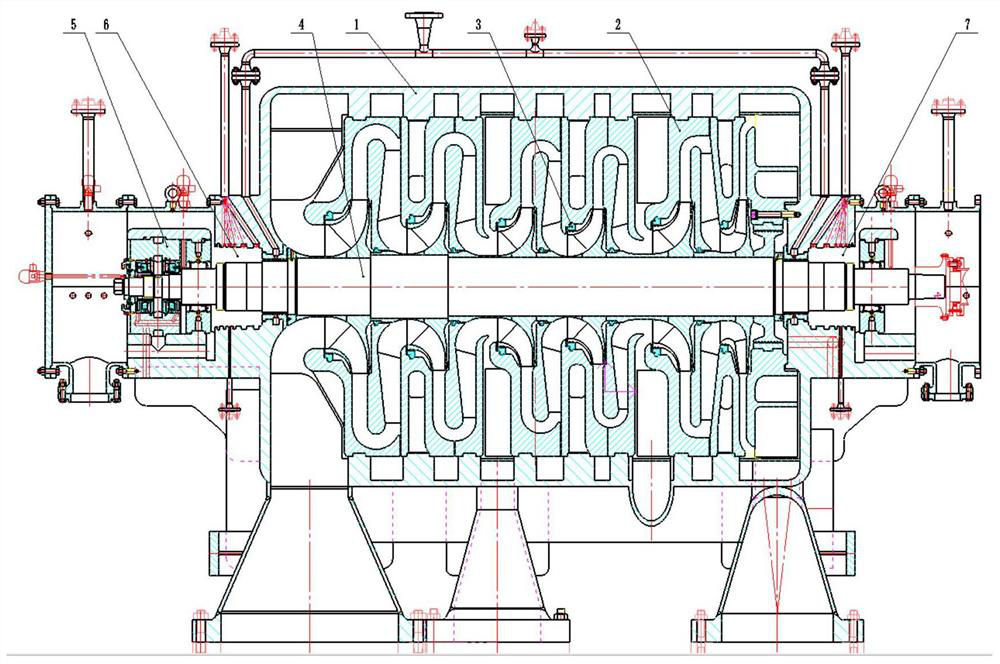

Propylene compressor

A compressor and propylene technology, applied in the field of compressors, can solve the problem that the material cannot be cooled down, and achieve the effect of stable operation and reduced axial thrust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

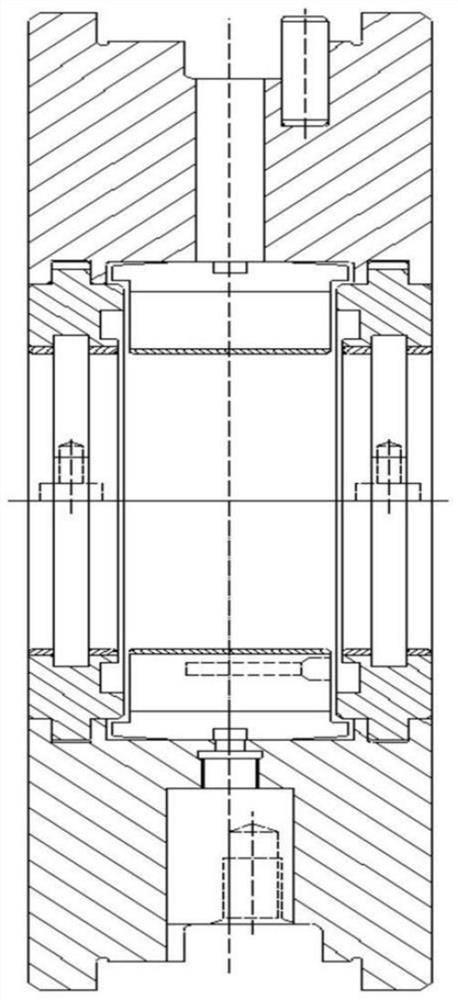

[0023] This embodiment 1 is a six-stage centrifugal compressor. The impeller adopts a three-element plus two-element closed-type forging and milling welded impeller. The number of impellers is 6, and the diameter of the impeller is 800mm. The compressor and the steam turbine have separate bases. The compressor and the steam turbine are composed of Diaphragm coupling connection.

Embodiment 2

[0025] This embodiment 2 is a six-stage centrifugal compressor. The impeller adopts three-element plus two-element closed-type forged milling welded impeller. The number of impellers is 6, and the diameter of the impeller is 800mm. The base of the compressor is independent, and the motor is connected with the gearbox. machine form.

Embodiment 3

[0027] Example 3 is a propylene compressor for a 1,000,000-ton / year olefin aromatics joint project. The impeller adopts a three-element plus two-element closed-type forging and milling welded impeller. The number of impellers is 6, and the diameter of the impeller is 800mm. The inlet flow rate is 91571Nm3 / h, inlet pressure 0.136Mpa(A), inlet temperature -40℃ process requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com