TC4 titanium alloy seamless tube and production method thereof

A production method, titanium alloy technology, applied in metal rolling, temperature control, etc., can solve the problems of high strength, low yield, and low production efficiency, and achieve the effects of reasonable process flow, high yield, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

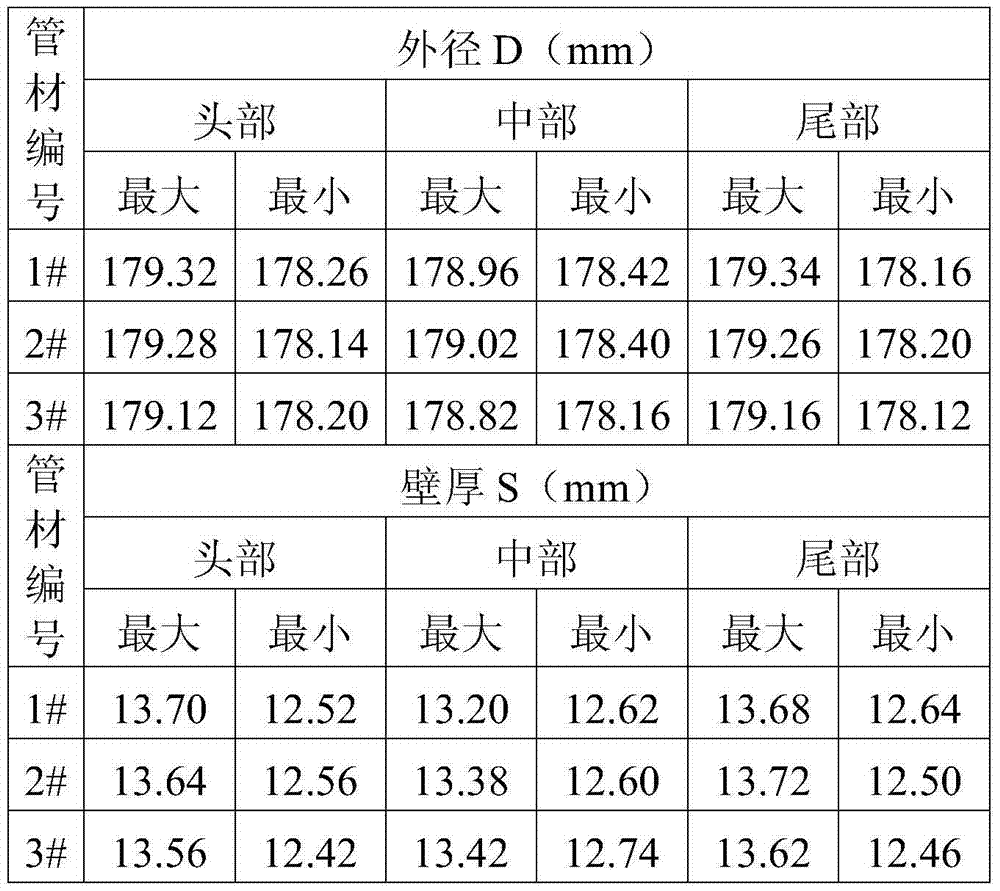

Image

Examples

Embodiment Construction

[0008] Hereinafter, the TC4 titanium alloy seamless pipe and the production method thereof of the present invention will be described in detail with reference to exemplary embodiments.

[0009] The production method of TC4 titanium alloy seamless pipe according to one aspect of the present invention comprises the following steps carried out in sequence: heating the round billet of TC4 titanium alloy to 920~980 ℃ in the annular heating furnace, wherein, the annular heating can be heated with pure natural gas Furnace, and the air-fuel ratio is controlled to be 11-13:1; the round billet is thermally centered on-line; cross-rolling and piercing are carried out, in which the total diameter reduction rate is controlled to be 9-16%, and the reduction rate before the top is controlled to be 2.5- 11%, the control ellipticity coefficient is 1.13-1.20, the control piercing speed is 0.2-0.5m / s; carry out precision cross-rolling to form blank tubes, in which the control total diameter reduc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com