Flux-cored wire for welding low-temperature steel and preparation method thereof

A technology of flux-cored welding wire and low-temperature steel, applied in welding equipment, welding medium, welding/cutting medium/material, etc., can solve difficult problems, achieve beautiful appearance, stable performance, low-temperature impact toughness and low-temperature crack resistance and other performance-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

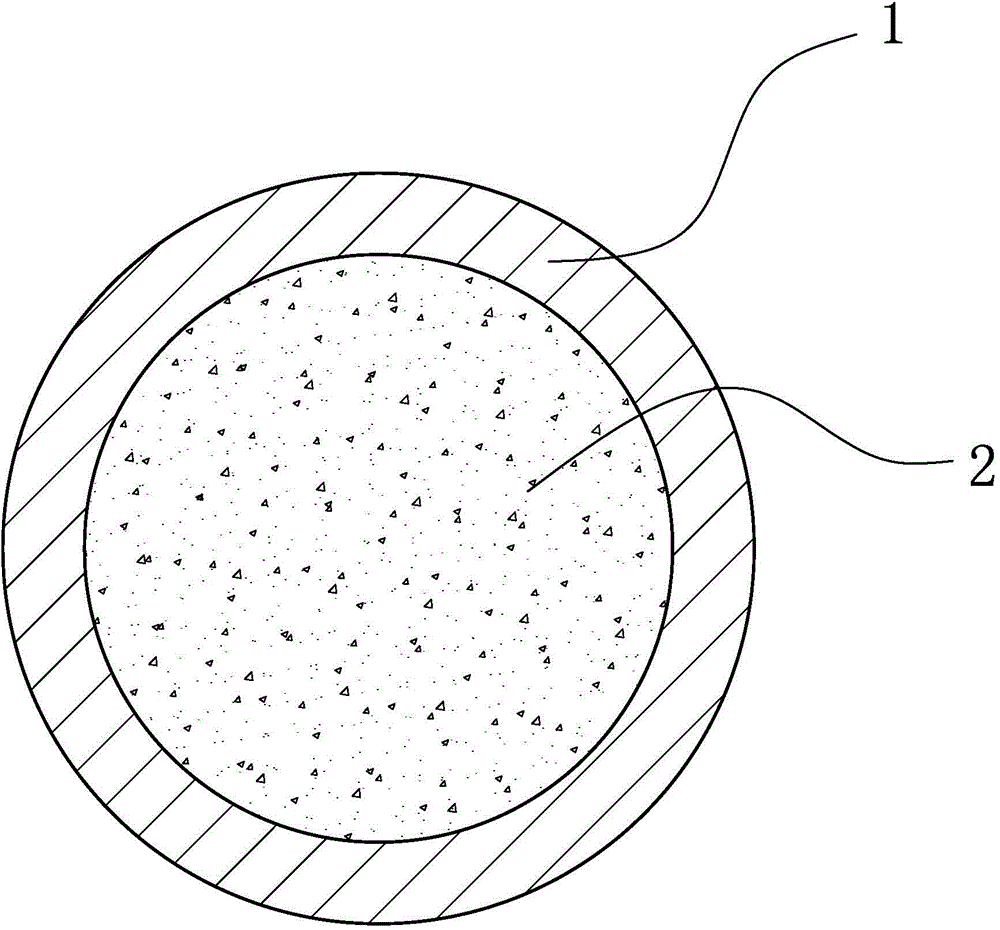

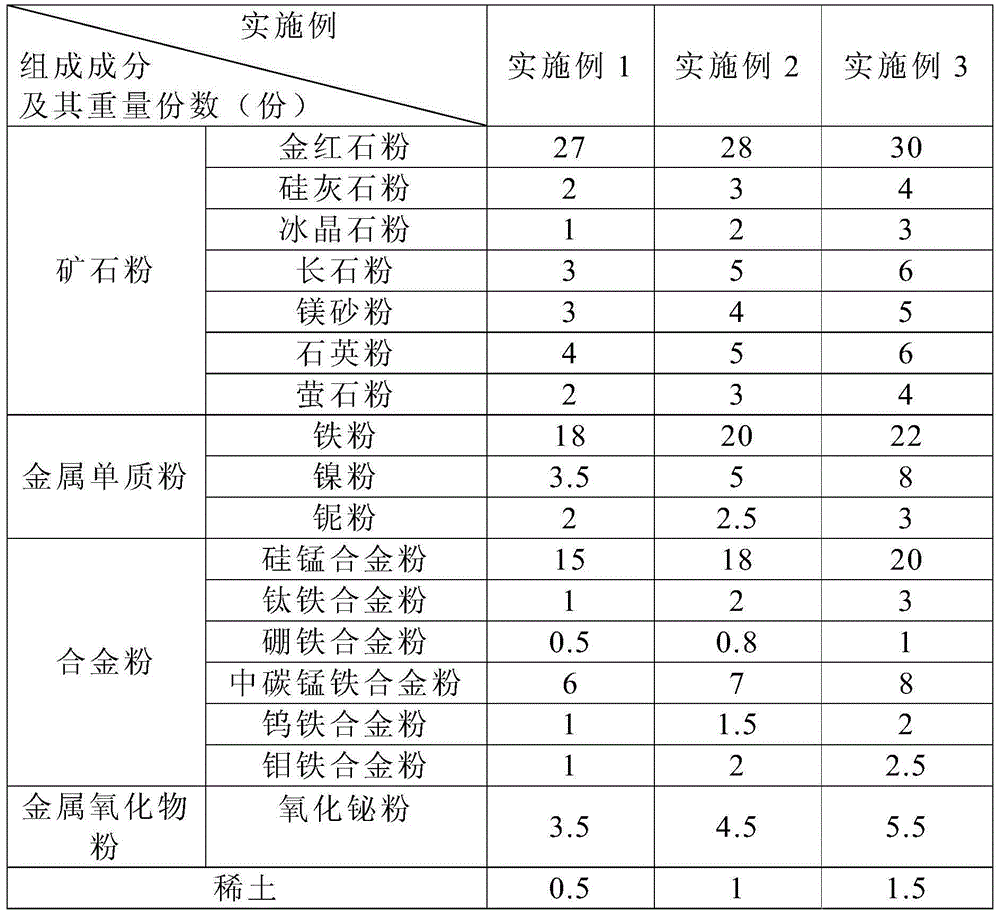

Embodiment 1

[0043] First, weigh the powder and weight parts of the flux-cored wire flux-core powder used for welding low-temperature steel in Example 1 in Table 1. The particle size of the powder is 60-160 mesh, and mix uniformly to prepare the flux-core powder. Then select the steel strip as the sheath of the flux-cored wire, draw the steel strip into a U-shaped groove structure, and add the above-mentioned prepared flux core powder accounting for 17% of the total weight of the flux-cored wire into the U-shaped groove, and then use a forming machine to After the U-shaped groove is closed, a through hole through the steel strip is formed along the axial direction of the steel strip, and the drug core powder is wrapped in the through hole. Finally, the steel strip wrapped with flux core powder is drawn and reduced in diameter through a wire drawing machine to obtain the final product flux cored wire for welding low temperature steel. The flux-cored wire used for welding low-temperature ste...

Embodiment 2

[0045] Firstly, according to the powder of the flux cored wire flux core powder used for welding low-temperature steel in Example 2 in Table 1 and its weight parts, the powder is weighed, the particle size of the powder is 60-160 mesh, and the flux core powder is prepared by mixing evenly. Then select the steel strip as the sheath of the flux-cored wire, pull the steel strip into a U-shaped groove structure, and add the above-mentioned prepared flux core powder accounting for 18% of the total weight of the flux-cored wire into the U-shaped groove, and then use a forming machine to After the U-shaped groove is closed, a through hole through the steel strip is formed along the axial direction of the steel strip, and the drug core powder is wrapped in the through hole. Finally, the steel strip wrapped with flux core powder is drawn and reduced in diameter through a wire drawing machine to obtain the final product flux cored wire for welding low temperature steel. The flux-cored w...

Embodiment 3

[0047] First, weigh the powder and weight parts of the flux-cored wire flux-core powder used for welding low-temperature steel in Example 3 in Table 1. The particle size of the powder is 60-160 mesh, and mix uniformly to prepare the flux-core powder. Then select the steel strip as the sheath of the flux-cored wire, pull the steel strip into a U-shaped groove structure, and add the above-mentioned prepared flux core powder accounting for 19% of the total weight of the flux-cored wire into the U-shaped groove, and then use a forming machine to After the U-shaped groove is closed, a through hole through the steel strip is formed along the axial direction of the steel strip, and the drug core powder is wrapped in the through hole. Finally, the steel strip wrapped with flux core powder is drawn and reduced in diameter through a wire drawing machine to obtain the final product flux cored wire for welding low temperature steel. The flux-cored wire used for welding low-temperature ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com