Aluminum oxide ceramics copper-clad plate and preparation method thereof

A technology of alumina ceramics and ceramic copper clad laminates, which is applied in the field of ceramic metallization, can solve the problems of high equipment requirements, difficult control of process conditions, complex process of alumina ceramic copper clad laminates, etc., and achieve the effect of low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

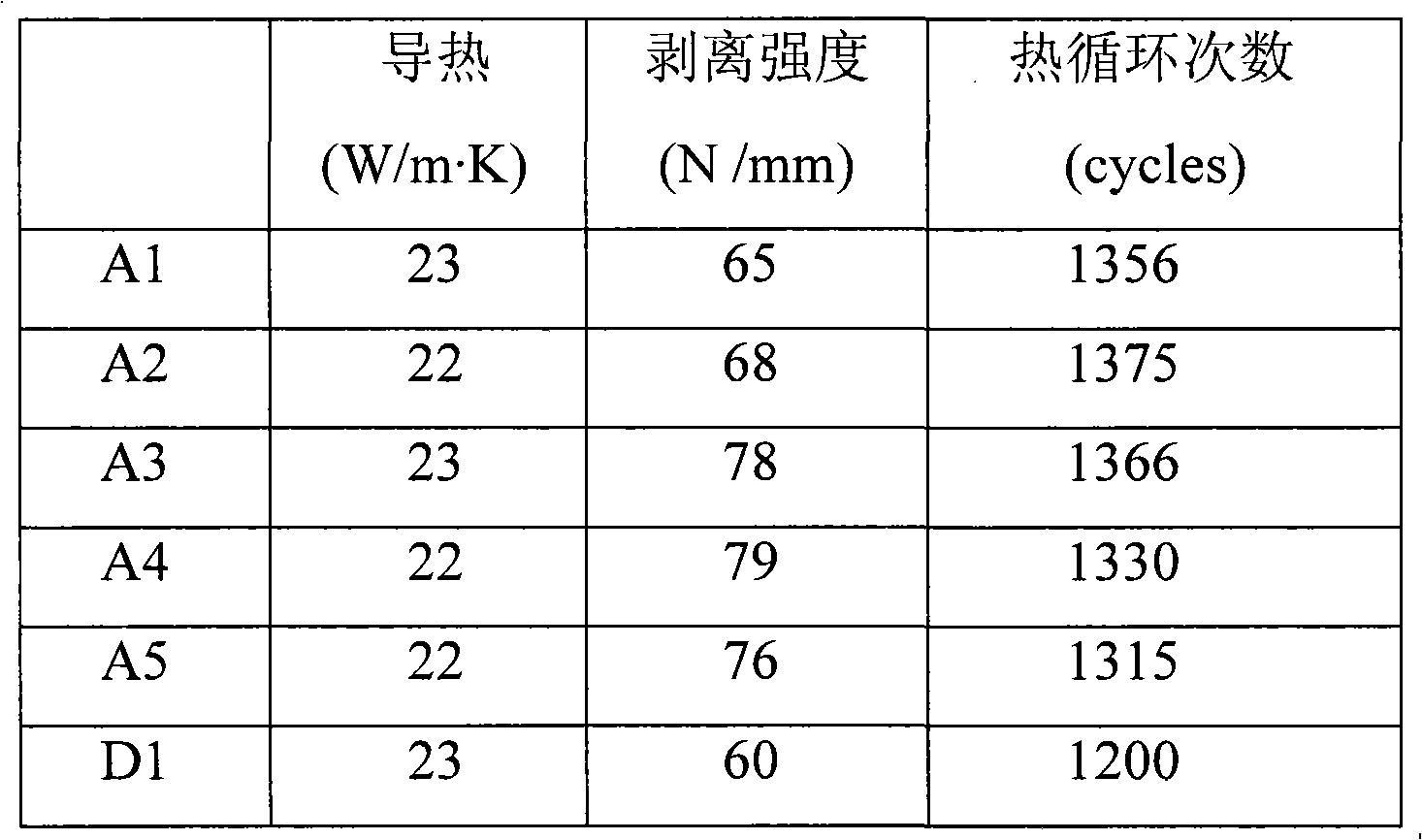

Examples

preparation example Construction

[0012] According to the preparation method provided by the present invention, the method for forming the copper oxide layer on the surface of the copper plate is to heat the copper plate to 200°C-300°C in the air for oxidation; the oxidation time is not particularly limited, as long as it can It is enough to form a dense copper oxide film layer. In order to make the copper plate well bonded to the ceramic, preferably, the oxidation time is 5-120min. This method is a method for preparing copper oxide known to those skilled in the art. This method is simple and requires low temperature. There is no special limitation on the content of oxygen, and it can be completed in an air environment.

[0013] According to the preparation method provided by the present invention, in order to form a copper oxide layer on only one surface of the copper sheet, before the copper sheet is put into the furnace, a flat glass plate or ceramic plate is placed under it to ensure that the back side is b...

Embodiment 1

[0024] (1) Cut the 0.3mm oxygen-free copper strip into 100*100mm size, after degreasing, pickling, water washing and drying, put a flat glass plate under it and put it into the room which has been heated to 280℃ In the oven, take it out after oxidizing for 5 minutes. The surface not in contact with the glass plate was provided with a 1 micron layer of copper oxide.

[0025] (2) One side of the copper oxide layer and Al with a thickness of 300 μm 2 o 3 The ceramic plates are contacted and stacked to form a composite body;

[0026] (3) Put the stacked body in the atmosphere furnace, raise the temperature to 1050 ° C, and keep it for 10 minutes to completely convert CuO into Cu 2 O, nitrogen with a purity of not less than 99.99% is introduced throughout the process;

[0027] (4) On the basis of step (3), raise the temperature to 1073° C. for sintering, keep the temperature for 10 minutes, and then lower the temperature to room temperature to produce alumina copper-clad lamina...

Embodiment 2

[0029] (1) Cut the 0.3mm oxygen-free copper strip into 100*100mm size, after degreasing, pickling, water washing and drying, put a flat glass plate under it and put it into the room which has been heated to 200℃ In the oven, take it out after oxidation for 120min. The surface not in contact with the glass plate was provided with a 30 micron copper oxide layer.

[0030] (2) One side of the copper oxide layer and Al with a thickness of 1000 μm 2 o 3 The ceramic plates are contacted and stacked to form a composite body;

[0031] (3) Put the stacked body in the atmosphere furnace, raise the temperature to 1000°C, and keep it for 60 minutes to completely convert CuO into Cu 2 O, nitrogen with a purity of not less than 99.99% is introduced throughout the process;

[0032] (4) On the basis of step (3), raise the temperature to 1065° C. for sintering, keep the temperature for 20 minutes, and then cool down to room temperature to produce alumina copper-clad laminate A12. Nitrogen g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com