Production process of hydrogen sulfide corrosion resistant forge piece

A production process and anti-hydrogen sulfide technology, applied in the field of forgings manufacturing, can solve problems such as corrosion, hydrogen sulfide easily corroded equipment, etc., achieve the effects of reducing P and S content, improving the ability of anti-hydrogen sulfide corrosion, and improving the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1: Studies have shown that H2S concentration has a significant impact on stress corrosion, and the cracking caused by wet H2S not only includes hydrogen sulfide stress corrosion (SSCC), hydrogen-induced (HIC), stress-oriented hydrogen-induced cracking (SOHIC) and hydrogen bubbling ( HB), etc., its damage sensitivity increases with the increase of H2S concentration, reaching the maximum value in saturated wet hydrogen sulfide.

[0032] The concentration of hydrogen sulfide in the liquid medium is for low carbon steel. When the concentration of H2S in the solution increases from 2PPm to 150PPm, the corrosion rate increases rapidly, but as long as it is less than 50PPm, the destruction time is longer. When the concentration of H2S increases to 1600PPm, the corrosion rate increases rapidly. When it is higher than 1600PPm - 2420PPm, the corrosion rate is basically unchanged, which shows that the corrosion of high-concentration hydrogen sulfide is not more serious than...

Embodiment example 2

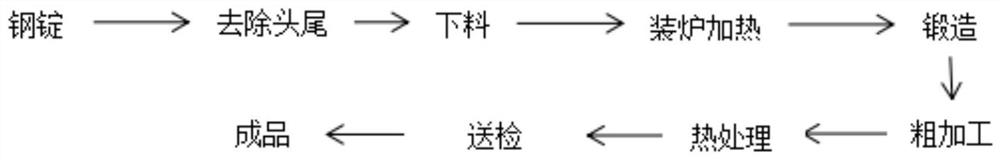

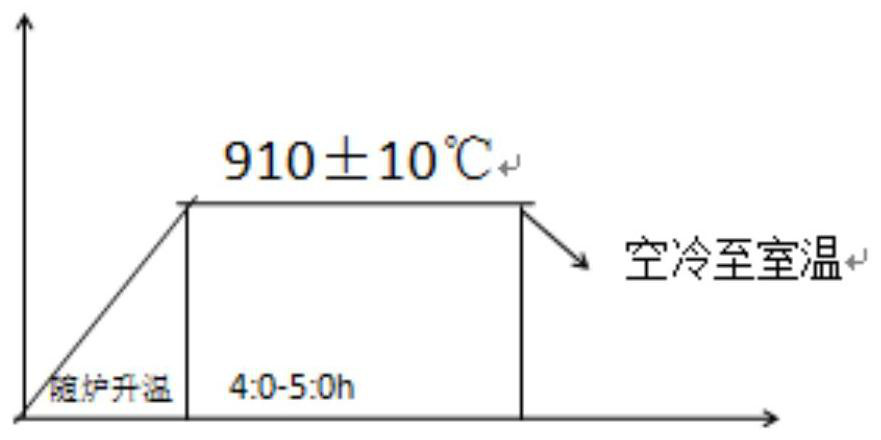

[0037] Implementation Case 2: A production process for a hydrogen sulfide corrosion-resistant forging, which includes the following steps in turn: blanking, furnace heating, forging, rough machining, heat treatment, inspection, finished product, and heat treatment. The heat treatment process includes rough The turning workpiece is heated to 910±10°C and kept warm for 240-300 minutes, and naturally cooled to room temperature in the air.

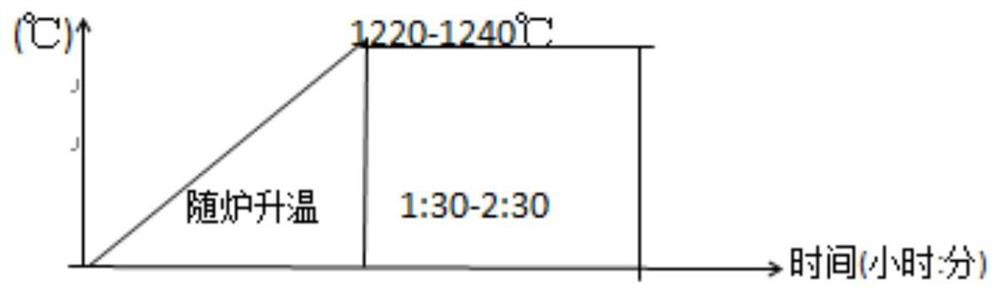

[0038] The blanking includes: removing harmful substances and inclusions from the steel ingot, blanking the material according to the weight and deviation of the bill of materials as required, and making a mark after loading to facilitate identification during furnace loading. The furnace heating includes: according to the heating process Raise the temperature to 1220-1240°C and keep it warm for 90-150 minutes. The forging includes: forging according to the size and technical requirements of the forging, repeatedly upsetting and elongating the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com