System for treating ship ballast water

A technology for ship ballast water and ballast water, which is applied in water treatment devices, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., and can solve the problems of long operation time and high energy consumption of replacement methods. To achieve the effect of reducing the survival rate, preventing adverse effects, and reducing the degree of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below with reference to the accompanying drawings and examples.

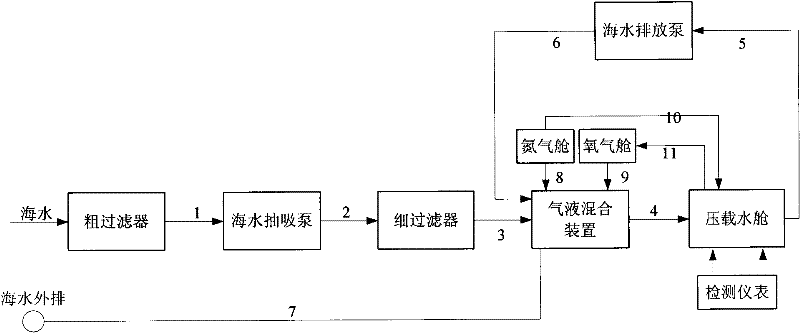

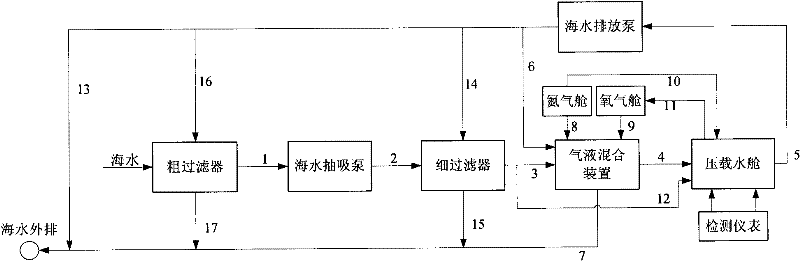

[0030] figure 1 It is a structural schematic diagram of the system for processing ship's ballast water according to the present invention. Such as figure 1 As shown, the system includes coarse filter, seawater suction pump, seawater discharge pump, fine filter, gas-liquid mixing device, ballast water tank, nitrogen tank, oxygen tank, sensor and control system. Wherein, the control system is not shown in the figure. The filter pore size of the coarse filter is 50-200μm, which is used to intercept large-sized debris; the filter pore size of the fine filter is 10-50μm. The coarse filter can be a stainless steel wire screen or a cyclone separator, and the fine filter can be a precision filter.

[0031]The inlet of the seawater suction pump is connected to the seawater suction port of the ship through pipeline 1, and the coarse filter is arranged on pipelin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com