GaN-based light-emitting diode (LED) epitaxial wafer capable of improving luminous efficiency, and preparation method and application thereof

A technology of LED epitaxial wafers and luminous efficiency, applied in the field of optoelectronics, can solve the problems of lower product yield, complicated process, quantum well damage, etc., and achieve the effects of cost reduction, simple process, and improved luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

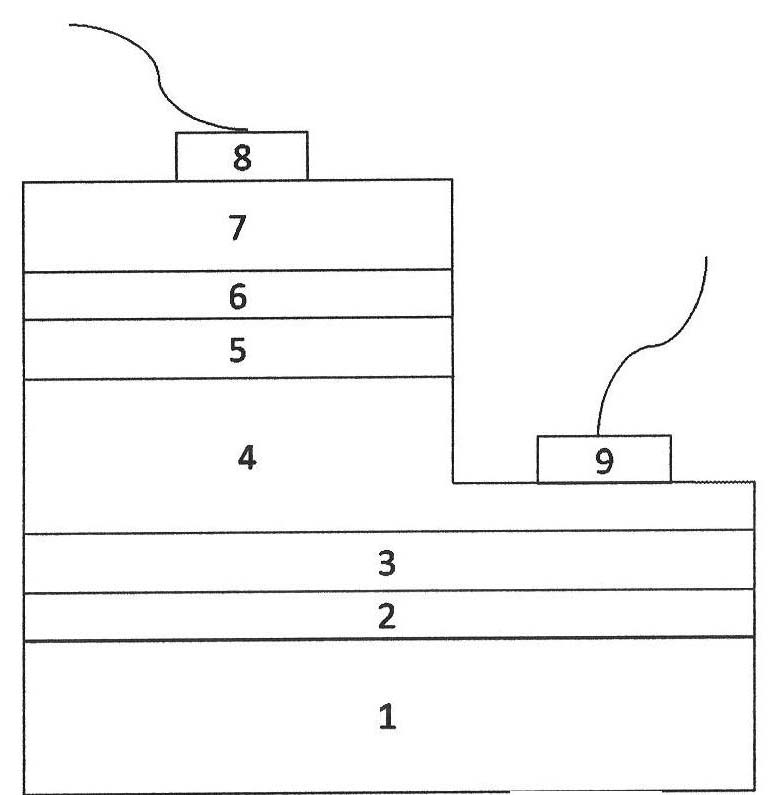

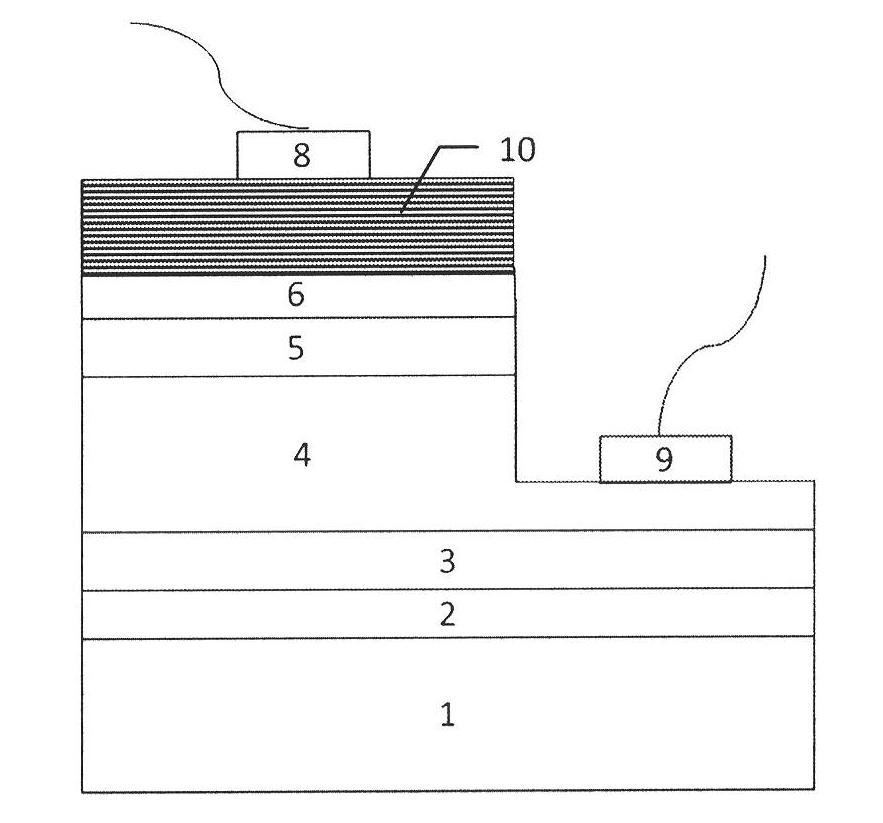

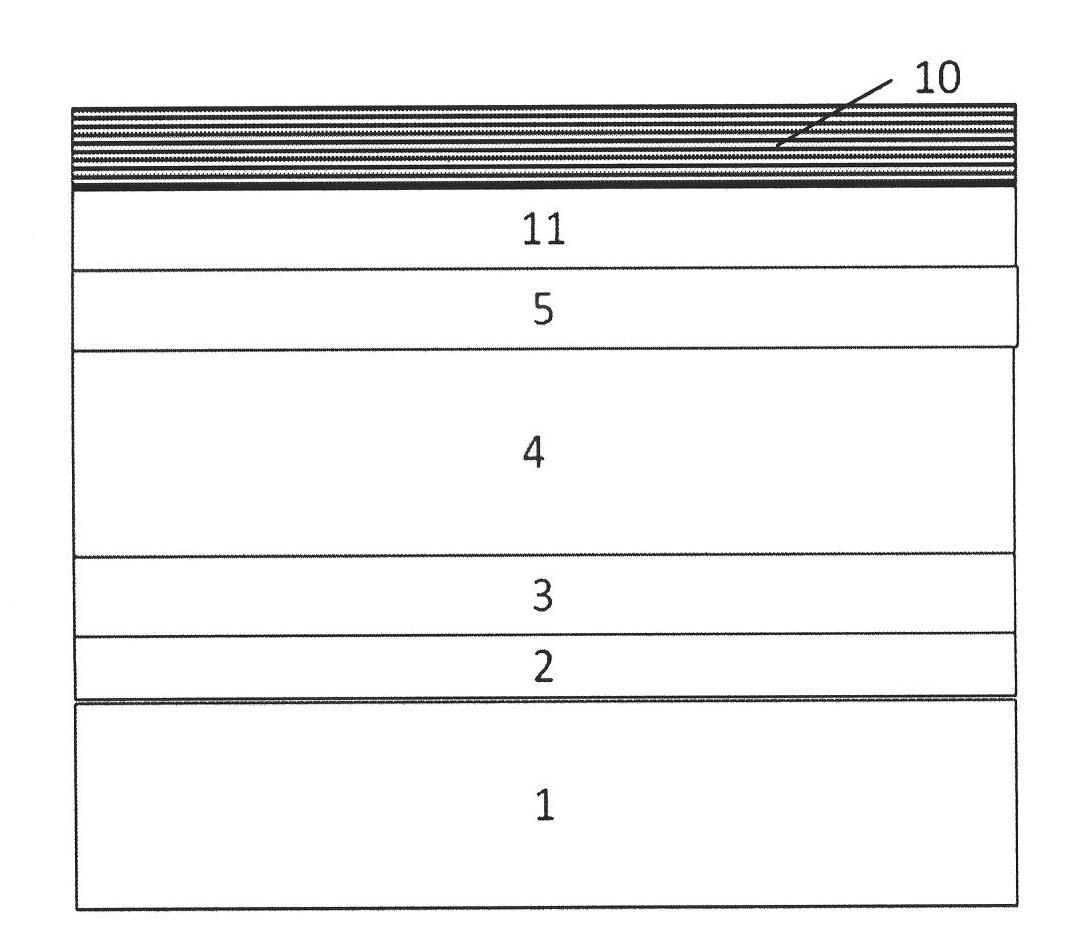

[0042] Embodiment 1: A GaN-based LED epitaxial wafer on a sapphire substrate is grown according to the following steps:

[0043] (1) Put the sapphire substrate 1 into the reaction chamber of the MOCVD equipment, heat it to 1150° C. under the hydrogen atmosphere, and process it for 15 minutes.

[0044] (2) growing a gallium nitride buffer layer 2 on the substrate at a growth temperature of 550° C. and a thickness of 30 nm;

[0045] (3) Non-doped GaN 3 and N-type GaN 4 are grown on the buffer layer 2 at a growth temperature of 1100° C., and the growth thicknesses are respectively 2 μm for non-doped GaN and 3 μm for N-type GaN. The silicon doping concentration of N-type GaN 4 is 1×10 19 / cm -3 .

[0046] (4) The multi-quantum well structure 5 is grown on the N-type gallium nitride 4, wherein the well layer is made of indium gallium nitride material, the barrier layer is made of gallium nitride material, the growth temperature is 750° C., and the multi-quantum well growth perio...

Embodiment 2

[0052] Follow the steps below to grow LED epiwafers:

[0053] (1) Put the silicon carbide substrate 1 into the reaction chamber of the MOCVD equipment, heat it to 1120° C. under a hydrogen atmosphere, and process it for 8 minutes.

[0054] (2) An aluminum nitride buffer layer 2 is grown on the aforementioned silicon carbide substrate 1 at a growth temperature of 1000° C. and a thickness of 200 nm.

[0055] (3) growing non-doped gallium nitride 3 and N-type gallium nitride 4 on the buffer layer 2, the growth temperature is 1050°C, and the growth thicknesses are respectively 2 μm for non-doped gallium nitride and 3 μm for N-type gallium nitride; N The silicon doping concentration of type GaN is 2×10 18 / cm -3 .

[0056] (4) The multi-quantum well structure 5 is grown on the N-type gallium nitride 4, the well layer is made of indium gallium nitride material, the barrier layer is made of gallium nitride material, the growth temperature is 750° C., and the repeated growth period...

Embodiment 3

[0060] Embodiment 3: grow LED epitaxial wafer according to the following steps:

[0061] (1) Put the sapphire substrate 1 into the reaction chamber of the MOCVD equipment, heat it to 1140° C. under a hydrogen atmosphere, and process it for 11 minutes.

[0062] (2) An AlGaN buffer layer 2 is grown on the above-mentioned sapphire substrate 1 at a growth temperature of 1000° C. and a thickness of 200 nm.

[0063] (3) Non-doped GaN 3 and N-type GaN 4 are grown on the buffer layer 2 at a growth temperature of 1100° C. and a growth thickness of 2 μm and 3 μm respectively. The silicon doping concentration of N-type GaN is 1×10 19 / cm -3 .

[0064] (4) The multi-quantum well structure 5 is grown on the N-type gallium nitride 4, the well layer is made of indium gallium nitride material, the barrier layer is made of gallium nitride material, the growth temperature is 750° C., and the repeated growth period of the multi-quantum well is 20.

[0065] (5) On the multi-quantum well struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com