Production method of caramel

A production method and caramel technology, applied in chemical instruments and methods, azo dyes, organic dyes, etc., can solve the problems of high cost, loss of energy consumption in production processes, low production efficiency, etc., and achieve reduced energy consumption and production cycle. The effect of shortening and reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

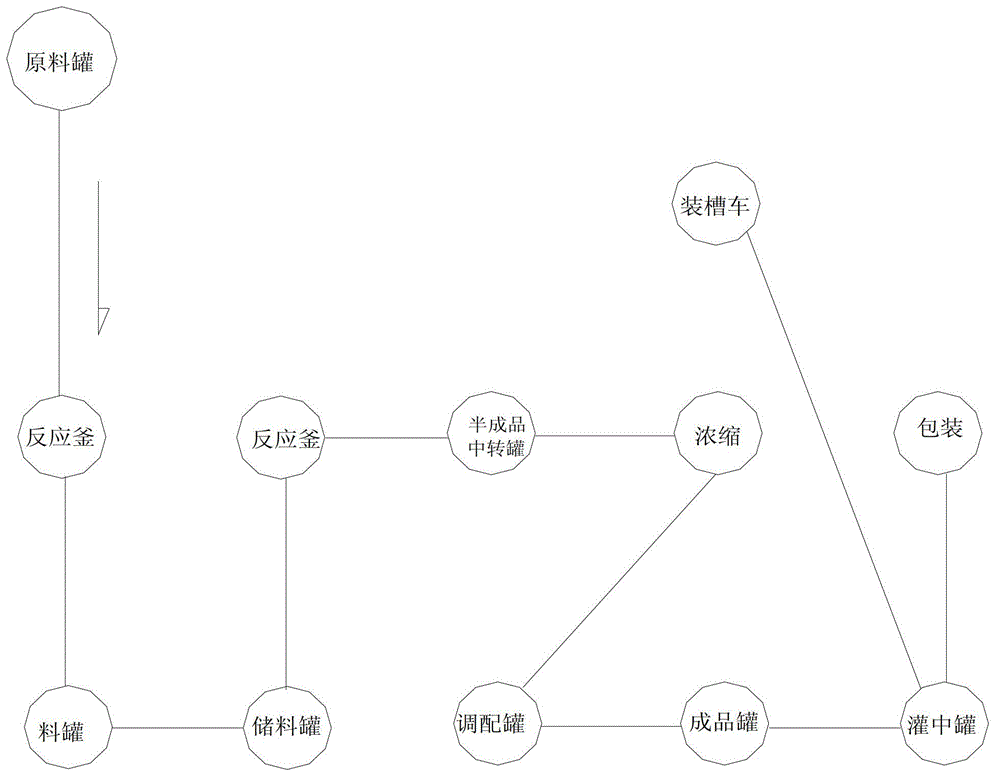

[0023] Such as figure 1 Shown, a kind of manufacture method of caramel, comprises the following steps:

[0024] In step 1, the raw material molasses stored in the raw material tank is hydrolyzed.

[0025] Step 2, the raw material molasses after the hydrolysis treatment is filtered through a plate and frame filter press.

[0026] Step 3: Clean the reactor, add water and edible alkali to the reactor, and heat the reactor to 90°C for at least 2 hours; when cleaning the reactor, preferably add 1500kg of water and 90kg of edible alkali to the reactor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com