Electromechanical rotor

A rotor and electromechanical technology, applied in the manufacture of stator/rotor body, magnetic circuit rotating parts, shape/style/structure of winding insulation, etc., can solve the problem of poor sealing between end plates and insulating shafts, greater influence of environmental factors, Increase the work process and other issues to achieve the effect of reducing procedures, reducing costs and improving friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

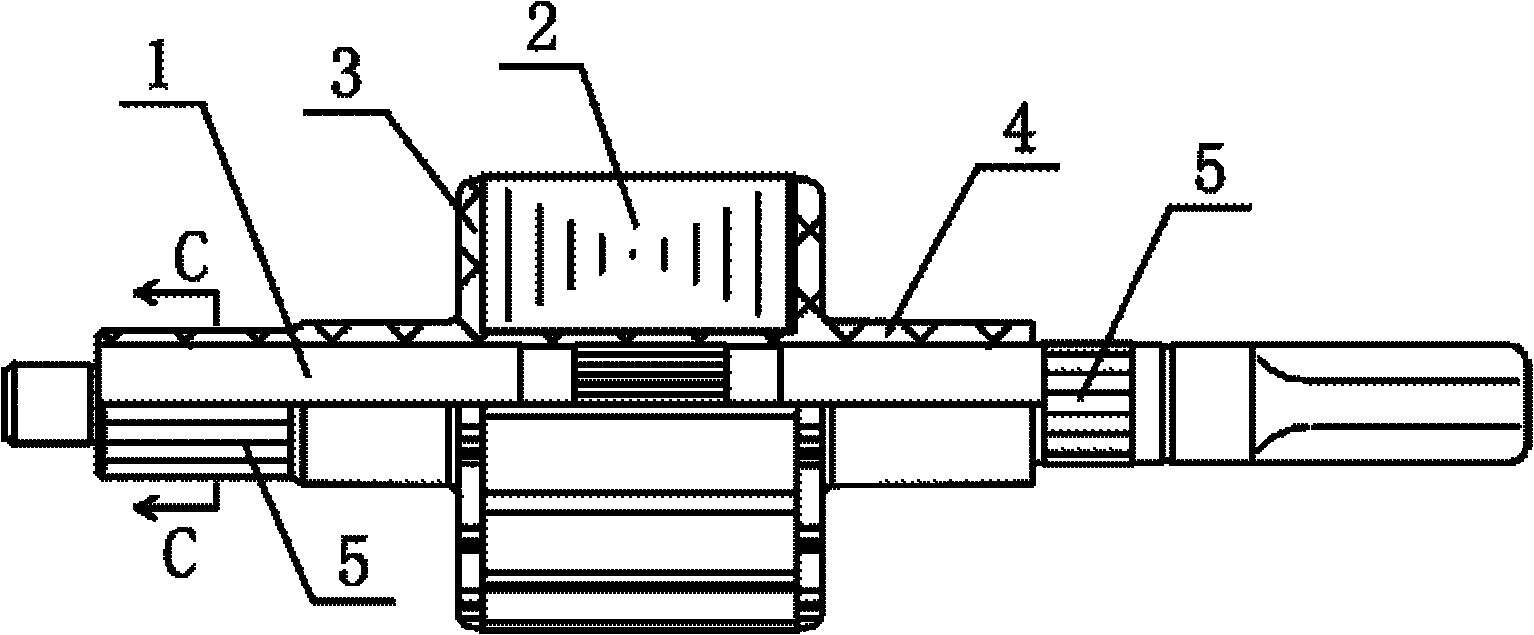

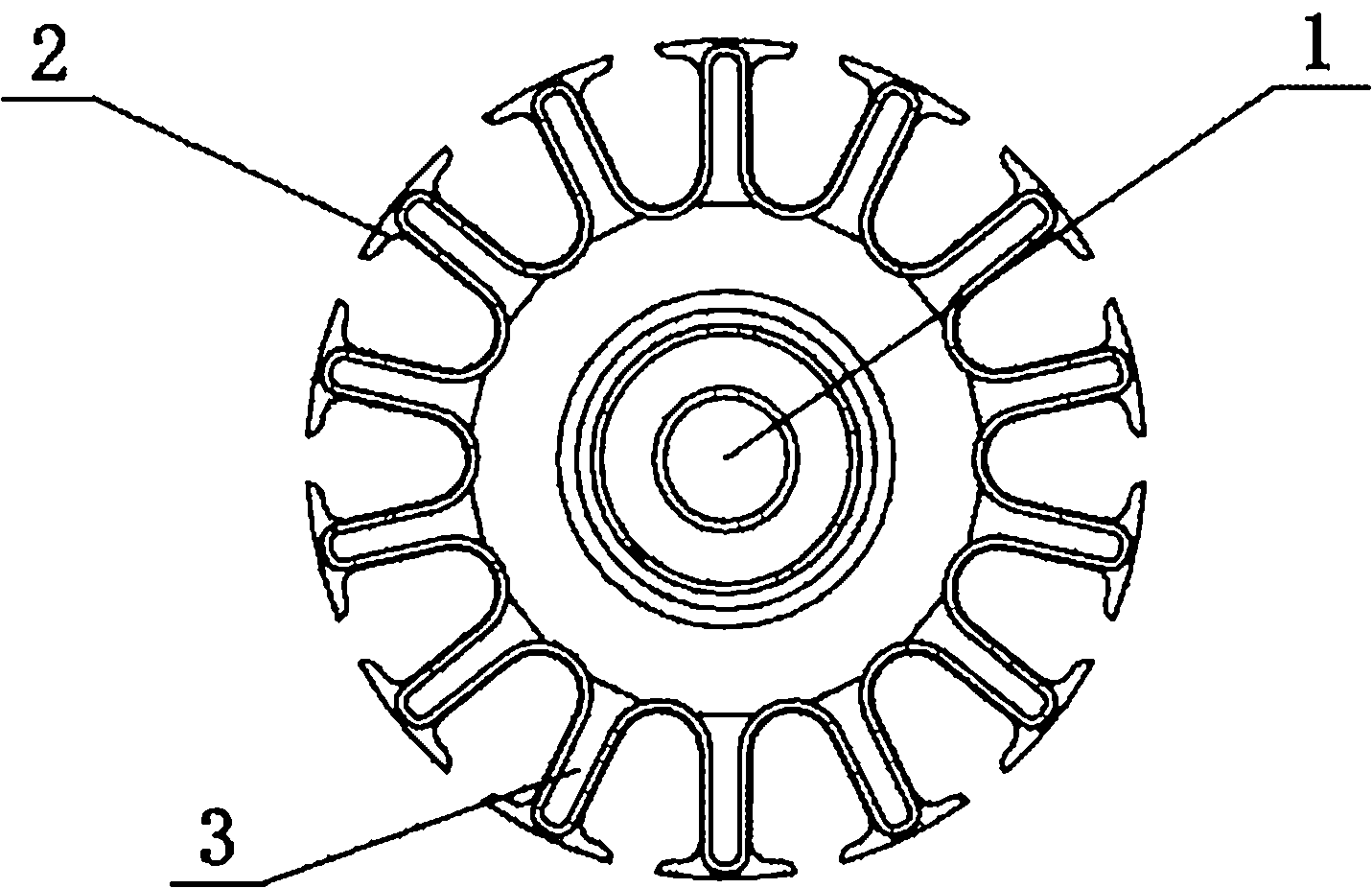

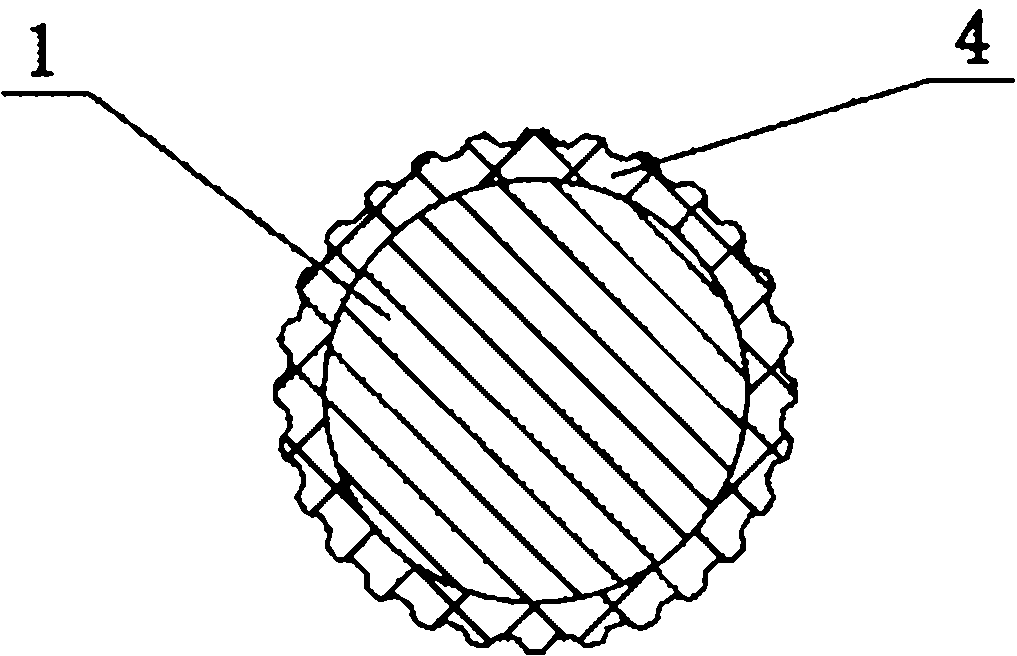

[0017] Such as figure 1 , figure 2 and image 3 As shown, an electromechanical rotor includes a rotating shaft 1, a rotor core 2, an end plate 3 made of BMC material and an insulating bushing 4 made of BMC material, and the insulating bushing 4 made of BMC material is attached to the rotating shaft 1 , the rotor core 2 is set on the rotating shaft 1 and connected to the rotating shaft 1 through the insulating sleeve 4 attached to the rotating shaft 1, and the insulating sleeves 4 on the left and right sides of the rotor core 2 are evenly provided with protrusions 5, the protrusions 5 It can improve the friction force and enhance the torque of the electronic rotor; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com