Corrosion resistant enamel hot pipe

A corrosion-resistant and enamel technology, which is applied in the field of corrosion-resistant enamel heat pipes, can solve problems such as decarburization, single-sided porcelain tube interior, oxidation, etc., achieve low strength loss, increase resistance to cold and heat shocks, and reduce processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

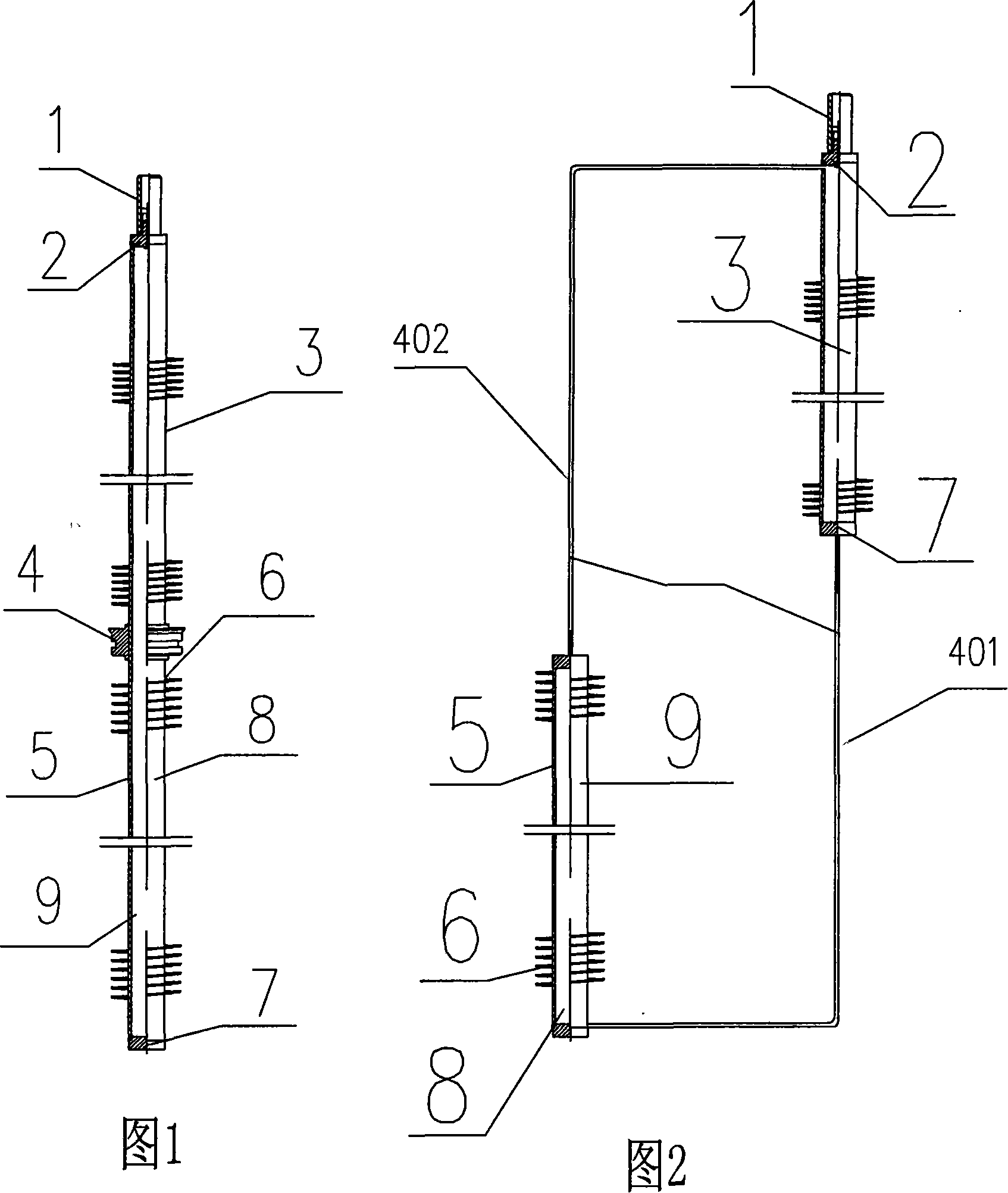

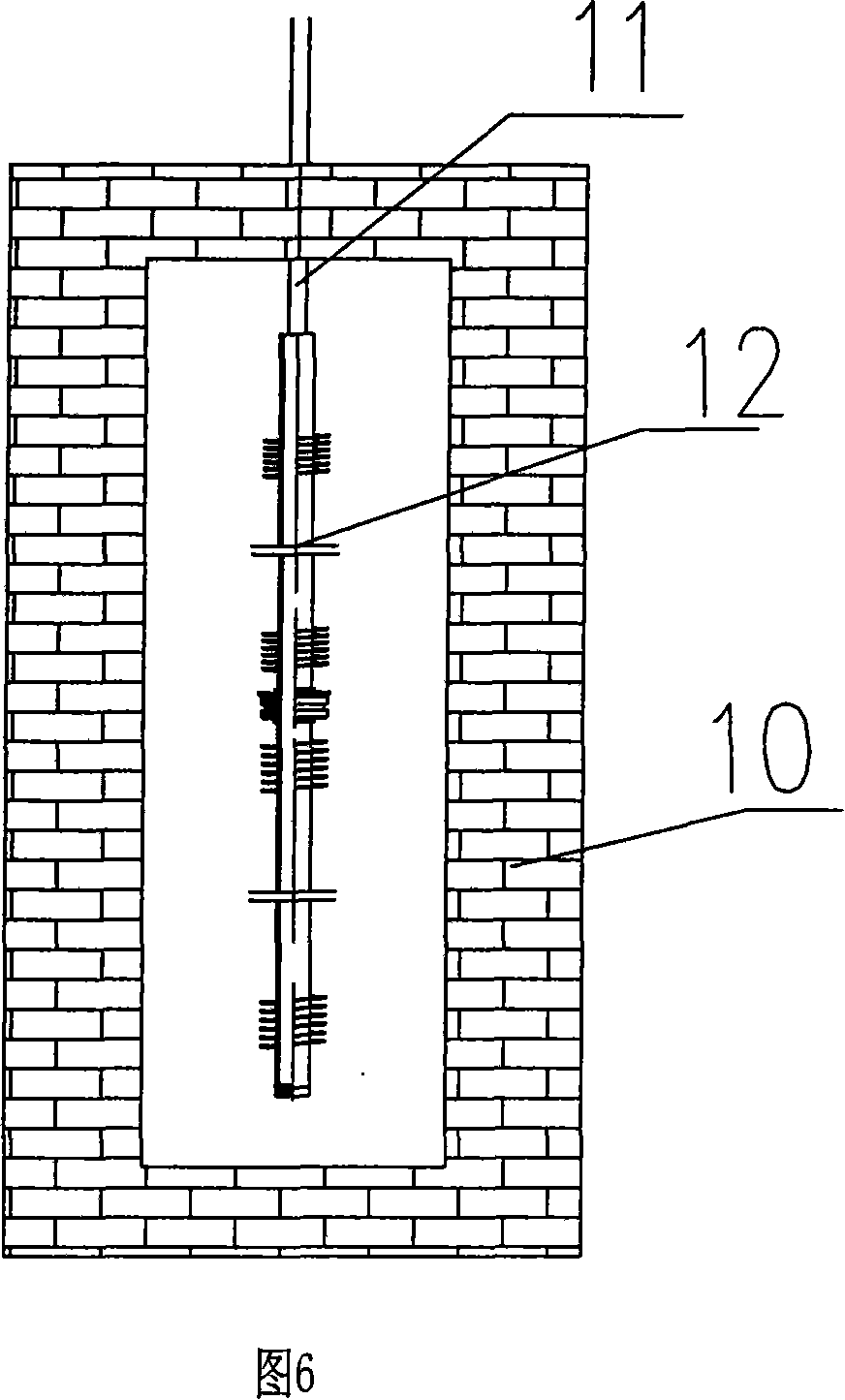

[0028] As shown in Figures 1, 4, 5, and 6.

[0029] A corrosion-resistant enamel heat pipe, which mainly includes a carbon steel base pipe composed of a cooling section 3 and a heating section 5, and fins 6 are connected to the outer surfaces of the cooling section 3 and the heating section 5, and the edges of the fins are arc-shaped Structure (shown in Figure 4 or Figure 5), the heating section 5 and the cooling section 3 are connected through the sealing installation body 4, the other end of the cooling section 3 is equipped with an upper head 2, and the upper head 2 is equipped with a protective cap 1 Inner enamel layer 9 with a thickness of 0.05-0.3 mm is enamelled on the inner surface of cooling section 3 and heating section 5, and the outer surface of cooling section 3 and heating section 5 and the outer surface of fin 6 are enamelled An outer enamel layer 8 with a thickness of 0.05-0.3 mm is fired, as shown in FIG. 1 .

[0030] During specific manufacturing, at first, ...

Embodiment 2

[0034] As shown in Figures 2, 4, 5, and 6.

[0035] A corrosion-resistant enamel heat pipe, which mainly includes a cooling section 3 made of carbon steel and a heating section 5 also made of carbon steel. A loop structure is formed between the cooling section 3 and the heating section 5 through connecting pipes 401 and 402. Cooling The upper end of the section 3 is equipped with an upper head 2, the upper head 2 is equipped with a protective cap 1, the lower end of the cooling section 3 is installed with a lower head 7, and the lower end of the cooling section 3 is connected with the lower end of the heating section 5 through a connecting pipe 401 , the upper end of the heating section 5 is connected to the upper end of the cooling section 3 through a connecting pipe 402, and fins 6 are connected to the outer surfaces of the cooling section 3 and the heating section 5, and the edges of the fins 6 on the heating section 5 are arc-shaped (see Figure 4 or Figure 5, the edge of t...

Embodiment 3

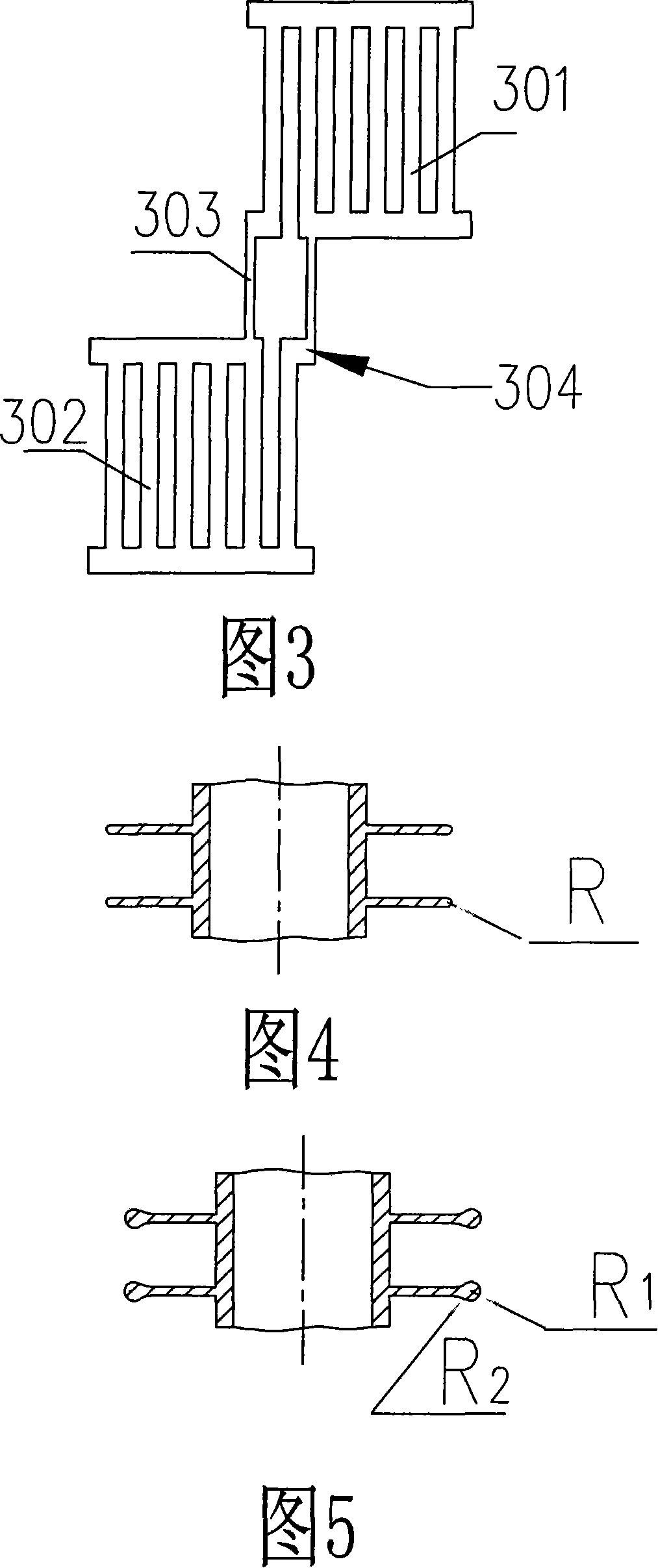

[0041] As shown in Figures 3, 4, 5, and 6.

[0042] A corrosion-resistant enamel heat pipe, which mainly includes a cooling section tube row 301 made of carbon steel and a heating section tube row 302 also made of carbon steel. The cooling section tube row 301 and the heating section tube row 302 are connected by connecting pipes 303 and 304 Form a ring structure, the lower end of each cooling section in the cooling section pipe row 301 is connected with the lower end of each cooling section in the heating section pipe row 302 through the connecting pipe 303, and the upper end of each cooling section in the cooling section pipe row 301 is connected with the connecting pipe 304. The upper ends of the cooling sections in the tube row 302 of the heating section are connected, and the inner and outer surfaces of the outer heating sections in the tube row 302 of the heating section are all enamelled with a thickness of 0.05-0.3 mm, as shown in FIG. 3 .

[0043] During the specific ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com