Dedicated machine tool for compound grinding of shaft washer raceway and flange of thrust aligning roller bearing

A technology of thrust self-aligning rollers and special machine tools, which is applied in the direction of grinding machines, grinding/polishing equipment, metal processing equipment, etc., and can solve the problems of low grinding line speed, low grinding efficiency, and poor grinding surface accuracy. Achieve the effect of improving efficiency, high feeding accuracy, and improving the quality of grinding surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

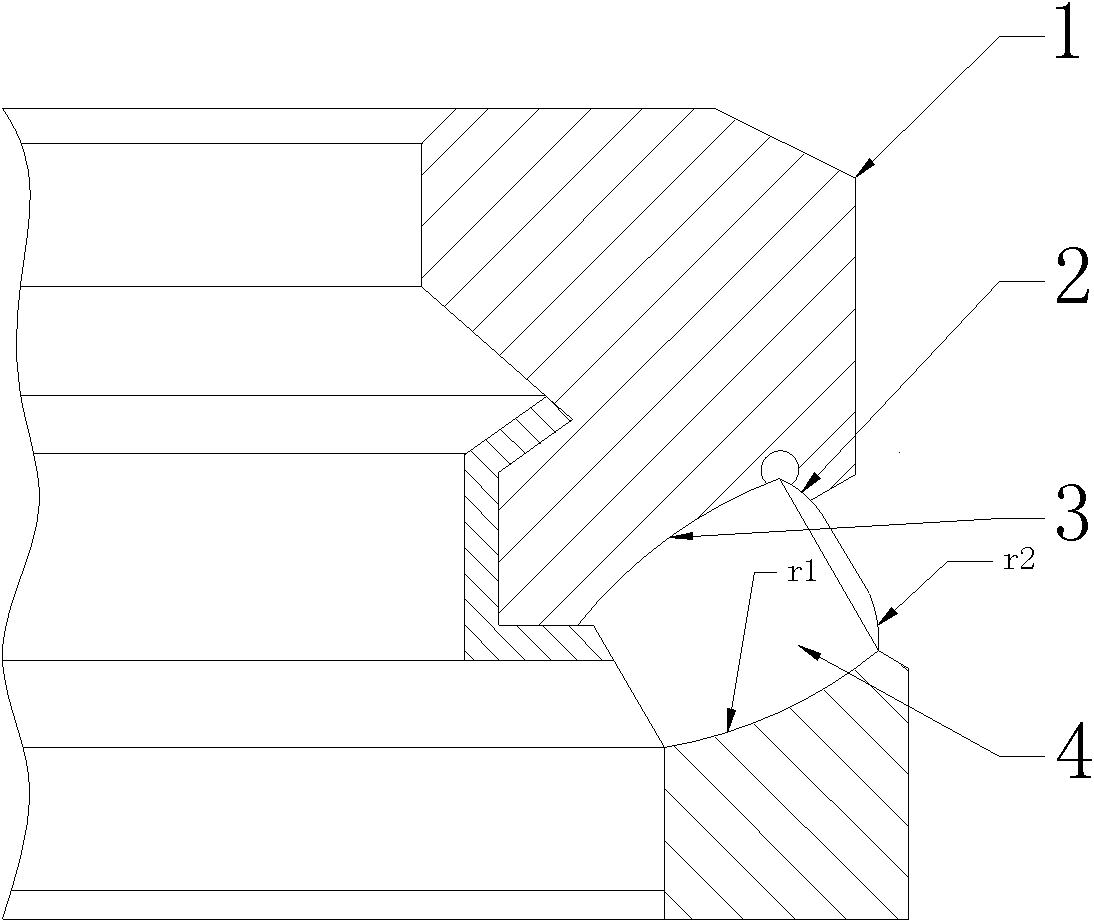

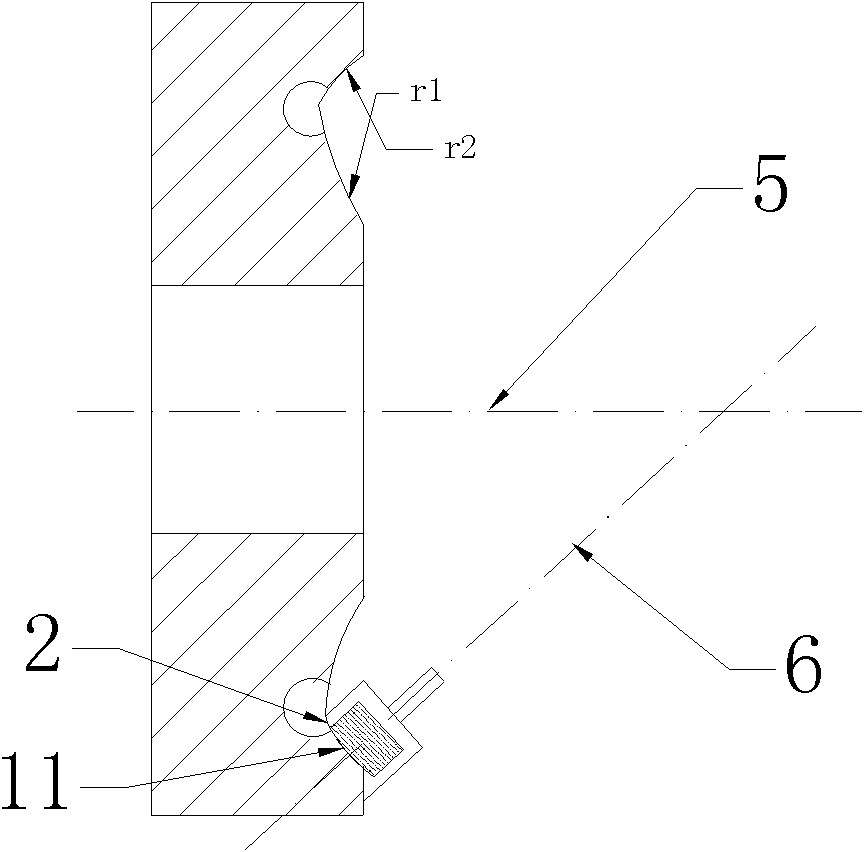

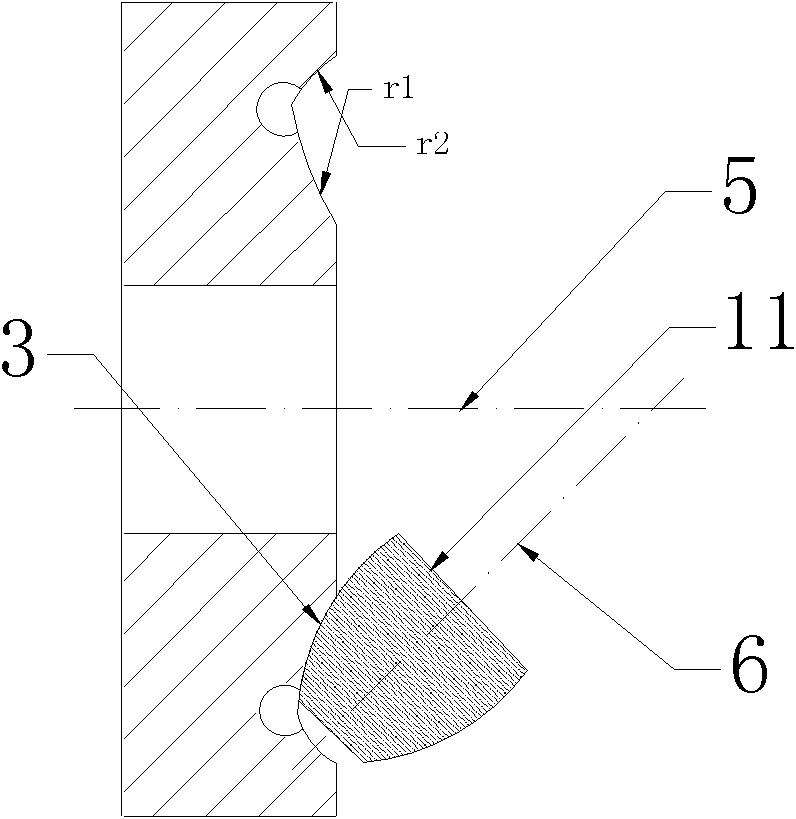

[0025] Depend on Figure 4 , 5 As shown, a workpiece device and a grinding wheel device are arranged on the bed surface of the special machine tool body (14) for thrust self-aligning roller bearing shaft ring raceway and rib compound grinding. Axlebox slideway 8, bedside axlebox 7 is placed on the bedside axlebox slideway 8, can slide forward and backward to adapt to the size of workpiece 15, and make the bedside axlebox 7 and the actual grinding feed by adjusting knob 17 Work piece 15 can have the position adjustment of ± 5 °; The grinding wheel device includes the following parts: the grinding wheel axle box 10 is fixed on the supporting plate 13, the supporting plate 13 is placed on the supporting plate slideway 16, and can slide left and right to adapt to the thickness and feed rate of the workpiece 15; the two sides of the grinding wheel axle box 10 The bed head axle box 7 can be set respectively to form a double-head grinding machine; the grinding wheel 11 is fixed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com