Machine for riveting heating series movable connection pipe seat and inlet and outlet pipes

A technology of flexible connection and inlet and outlet pipes, which is applied in the field of automobile heaters, can solve the problems of inconvenient operation and huge equipment, and achieve the effects of simple structure, improved production efficiency and quality, and expanded general performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

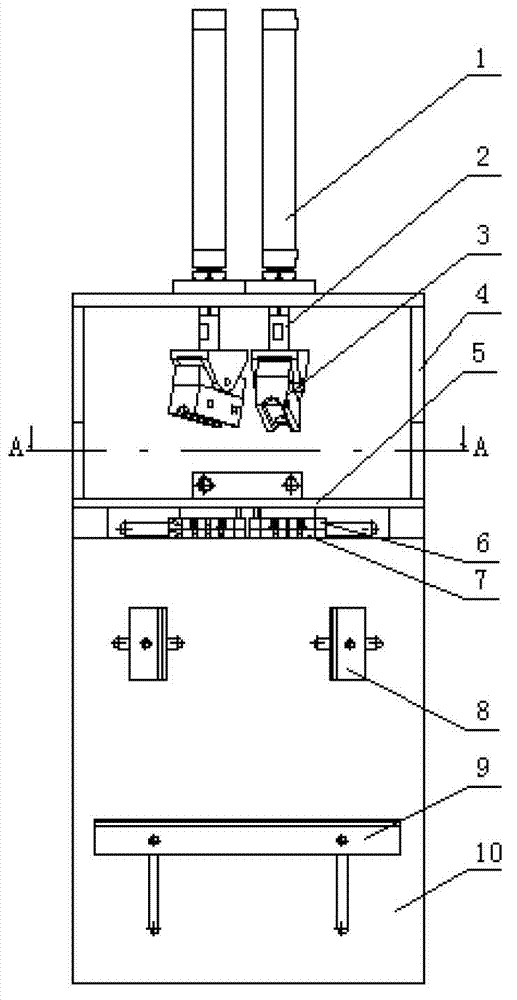

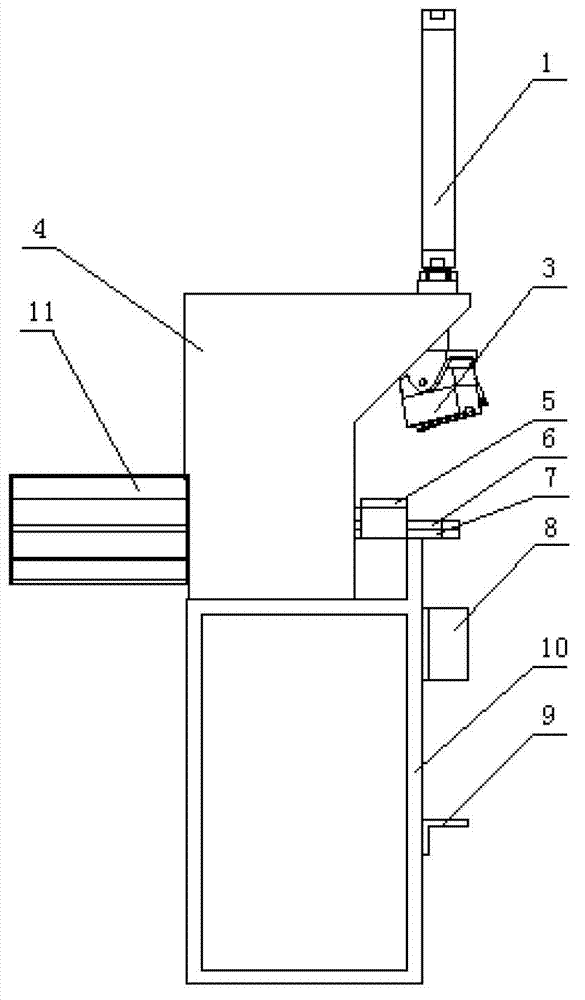

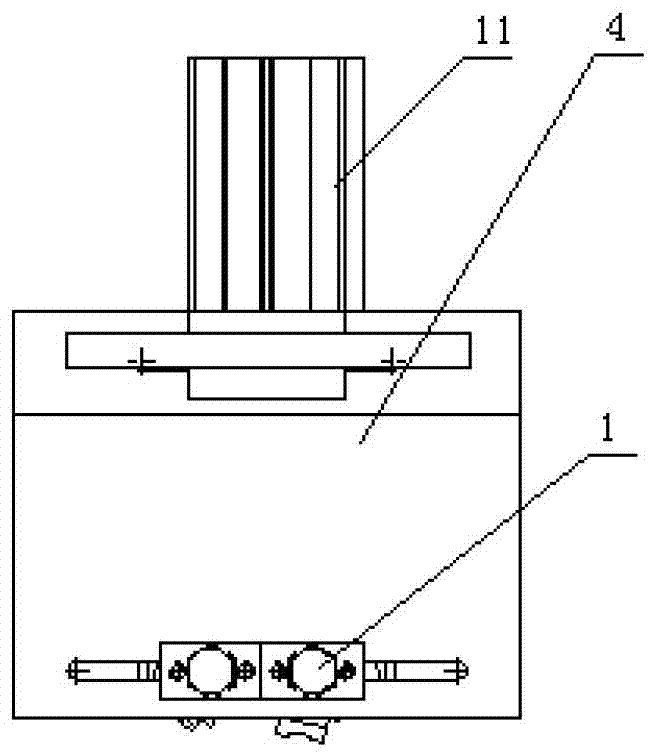

[0023] A riveting machine for warm air series live-joint pipe sockets and inlet and outlet pipes, including an upper bracket 4, a lower bracket 10, an upper pressure cylinder 1, a side push cylinder 11, a pipe holder 3, a riveter, a side mounting seat 8, and a lower bracket Frame 9, the upper bracket and the lower bracket are fixedly installed up and down, two side mounts and a lower bracket are respectively fixed on the front of the lower bracket, the heater is placed on the lower bracket, and the heater is adjusted and positioned by the two side mounts; The upper plane of the lower bracket in the upper bracket is fixed with a riveting device, and the side pushing cylinder is fixed at the rear of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com