Electroplating diamond grinding block and its production

A technology of electroplating diamond and diamond, which is applied in the manufacture of tools, metal processing equipment, abrasives, etc., can solve the problems of many processes, low output, and long time, and achieve the effects of increasing output, saving processes, and shortening working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

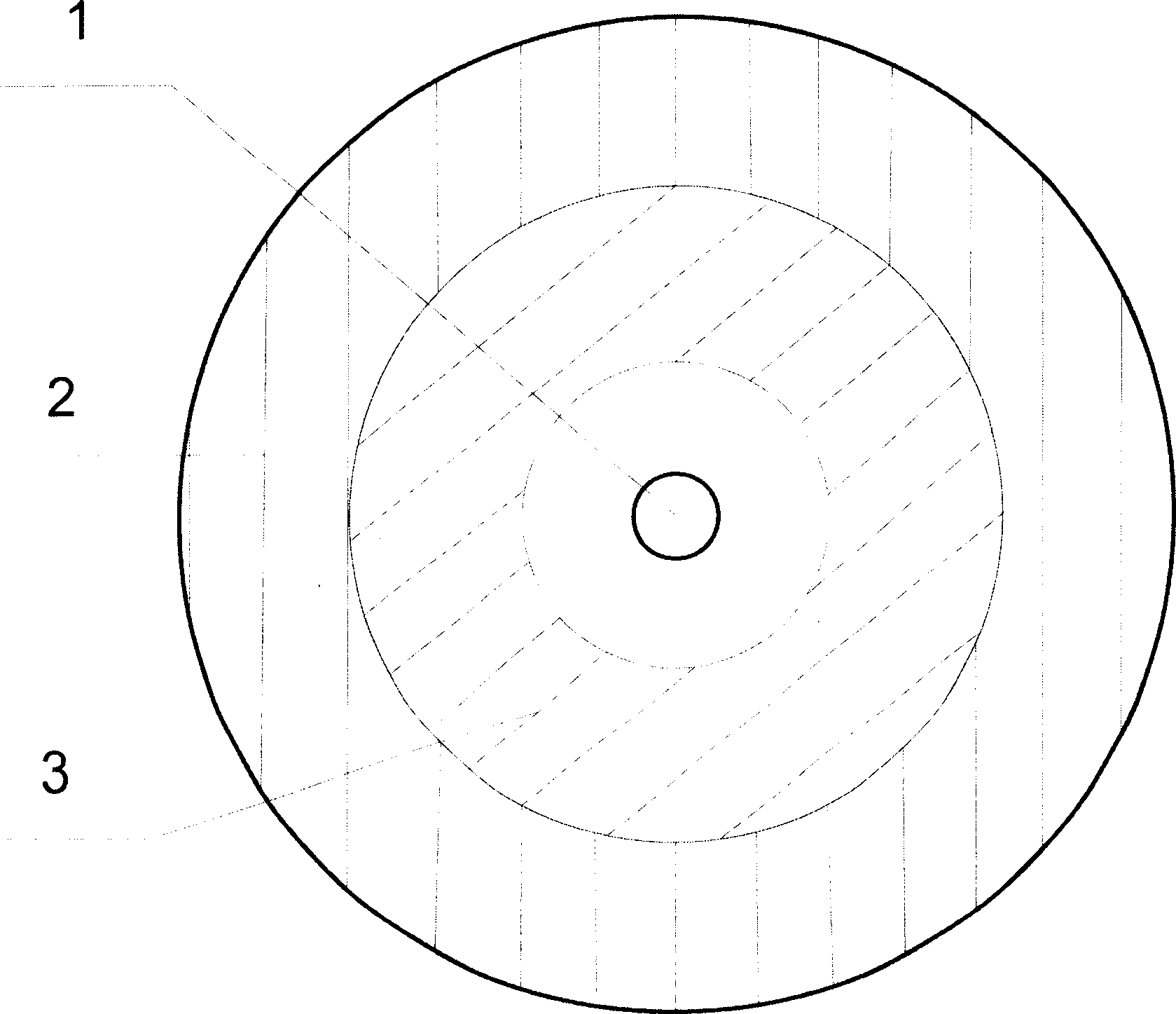

[0011] The embodiment is an electroplated diamond grinding disc whose outer ring surface is a coarse-grained diamond abrasive layer and whose inner ring surface is a fine-grained diamond abrasive layer.

[0012] In order to manufacture the above-mentioned electroplated diamond grinding disc, the process includes bottom nickel plating, diamond abrasive layer, cleaning and other processes, which is characterized in that the process of upper diamond abrasive layer adopts partial covering and partial electroplating, that is, the fine-grained diamond abrasive is first covered On the first part, coarse-grained diamond abrasives are applied; then the cover is removed, and fine-grained diamond abrasives are applied; two diamond abrasive layers of different particle sizes are plated on the base of the grinding disc steel sheet. This process not only ensures that the coarse-grained diamond will not be mixed into the fine-grained diamond abrasive layer, but also ensures that the working s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com