Straddle type monorail PC track girder construction method inside circular cross section tunnel

A straddle-type monorail and construction method technology, which is applied in the direction of tracks, roads, buildings, etc., can solve the problems that the beam erecting machine and the beam transporter cannot walk on the arc surface, the track has a large manpower and material cost, and an additional process is added. , to achieve the effect of convenient and flexible horizontal adjustment, improving construction efficiency and reducing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

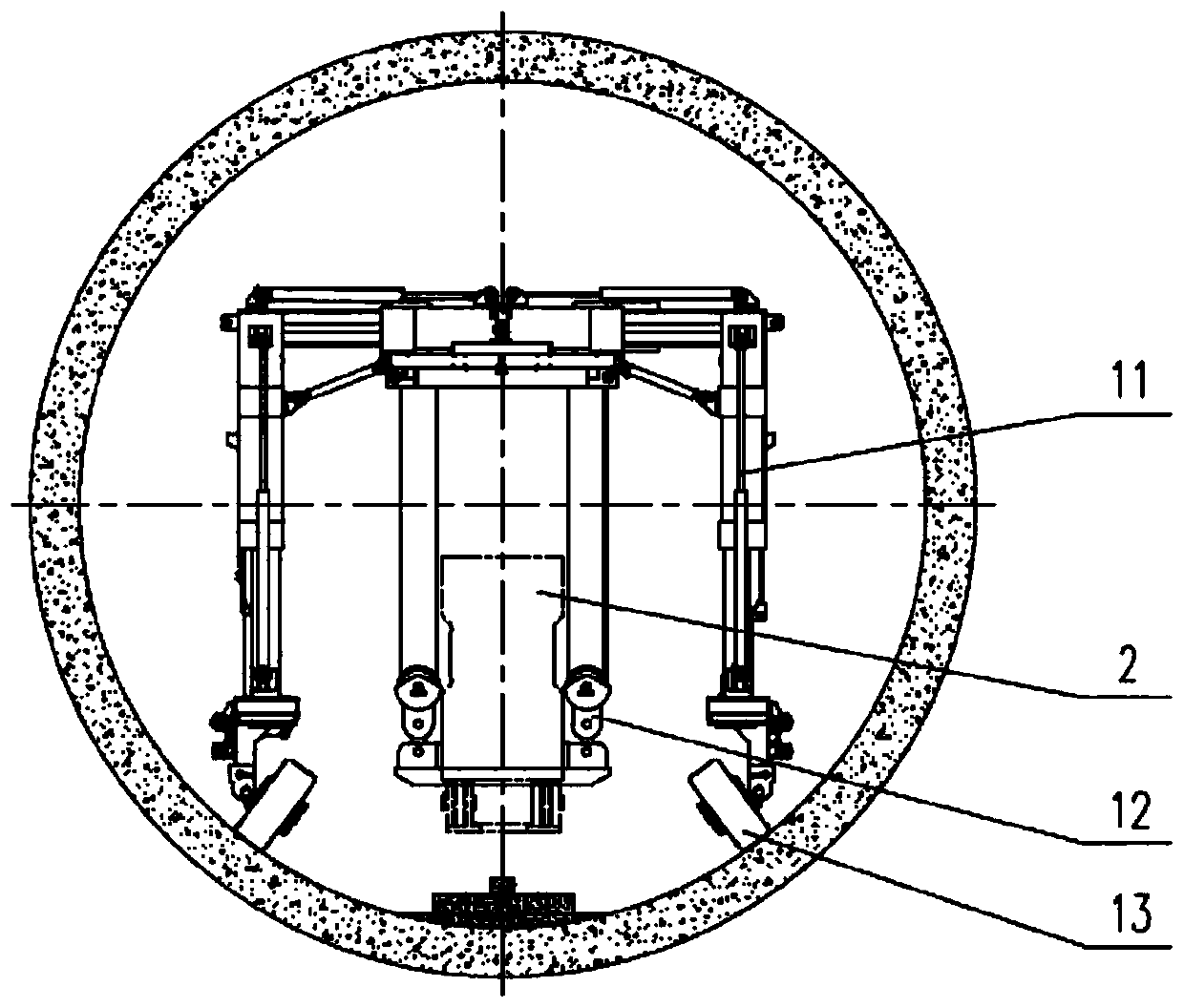

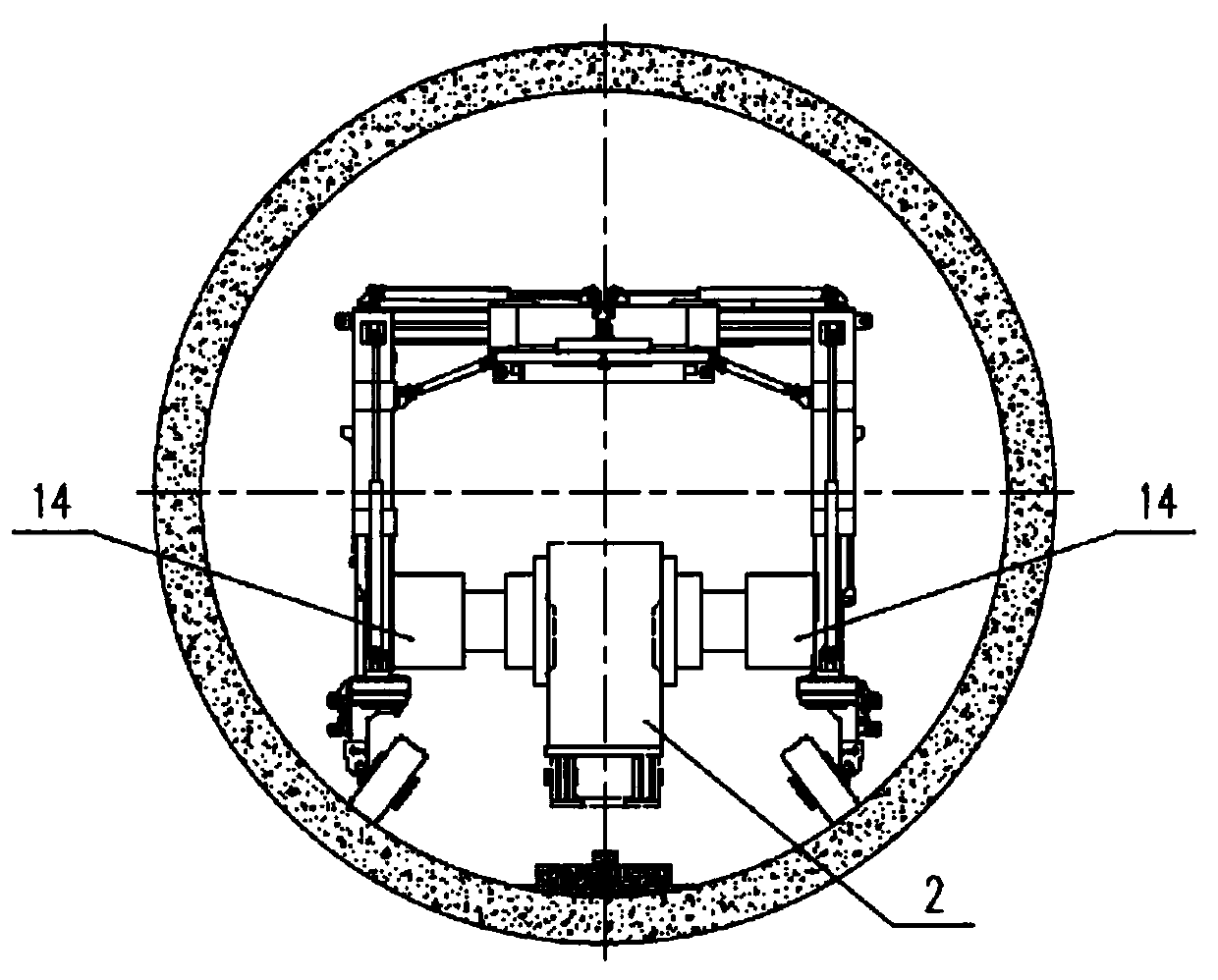

[0034] like Figure 5 A construction method for a straddle-type monorail PC track beam in a tunnel with a circular section as shown, comprising the following steps:

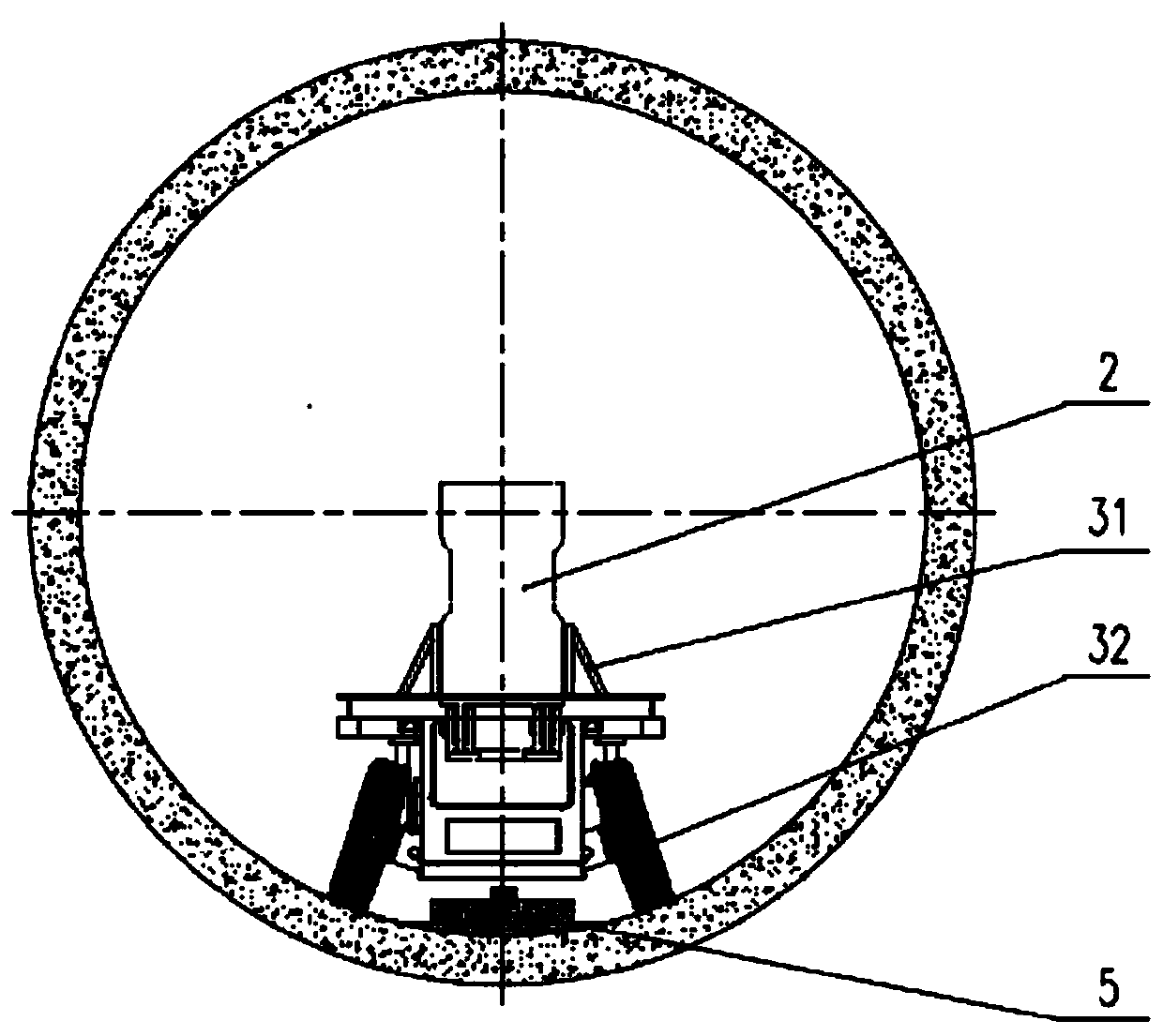

[0035] Step 1. Provide a self-deformable tire-type beam erecting machine 1 and a self-deformable tire-type beam transport vehicle 3 that can walk on curved surfaces;

[0036] Step 2: Install and fix the PC track beam 2 on the self-deformable tire-type beam transport vehicle 3, and drive the self-deformable tire-type beam erecting machine 1 into the circular cross-section tunnel 4 to be in place;

[0037] Step 3: The self-deformable tire-type beam transport vehicle 3 transports the PC track beam 2 into the self-deformable tire-type beam erecting machine 1. At this time, the self-deformable tire-type beam transport vehicle 3 is l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com