Feeding and discharging mechanical arm and device for stamping process

A technology of manipulator and mechanical arm, applied in the direction of program control manipulator, manipulator, feeding device, etc., can solve the problems of not being able to realize mechanized production, relying on manual loading and unloading, etc., to improve efficiency, flexibility and safety, to overcome the application of single Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

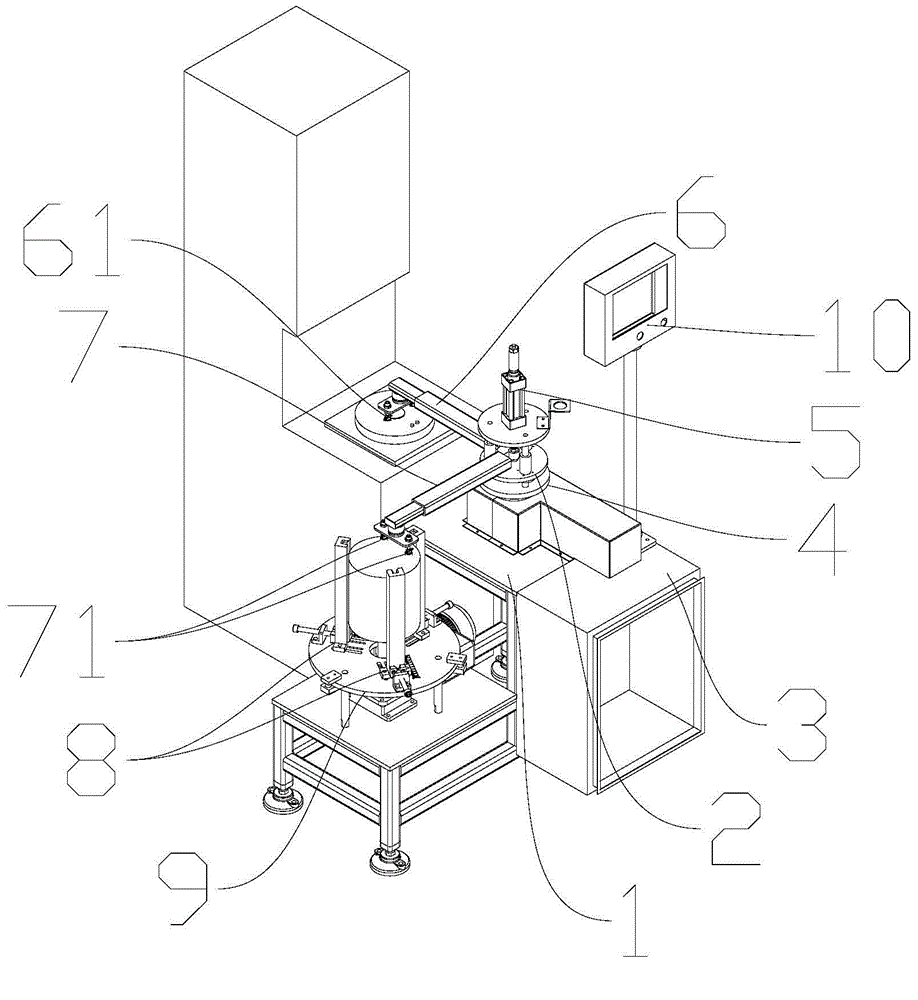

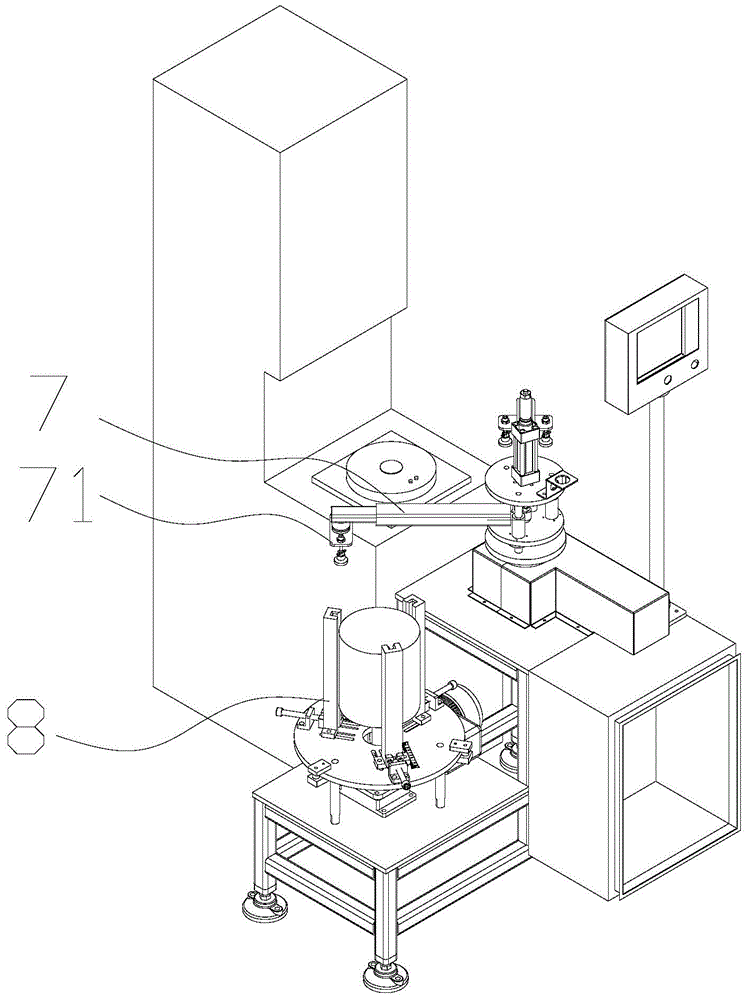

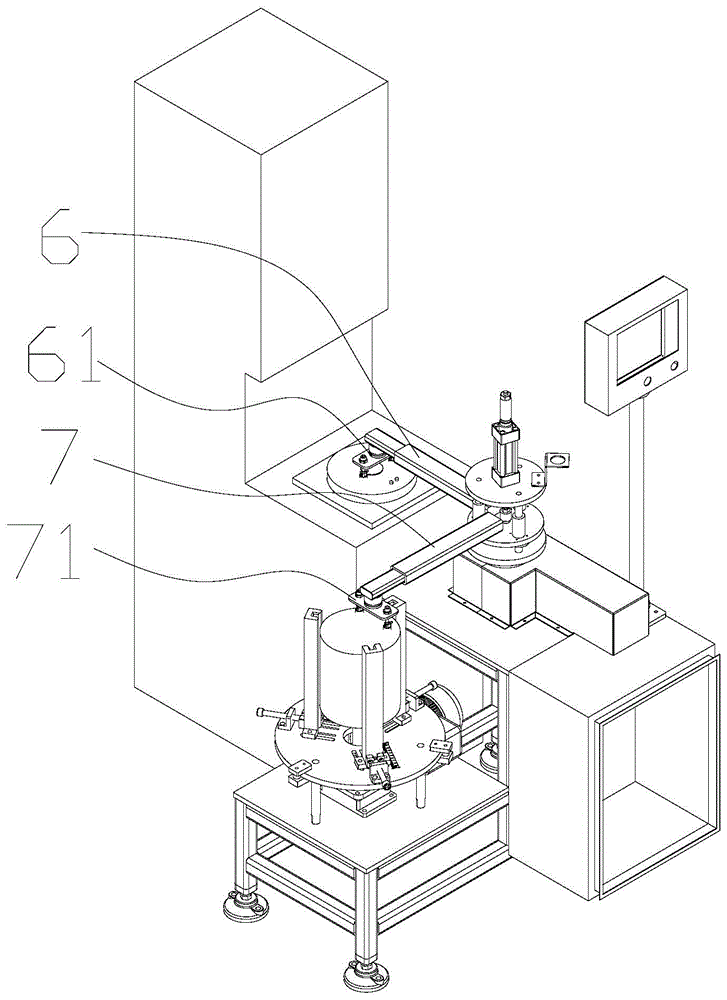

[0024] A loading and unloading manipulator used in the stamping process provided by the present invention, such as figure 1 As shown, the loading and unloading manipulator used in the stamping process is arranged between the loading platform and the stamping equipment, and its structure includes:

[0025] Electric control box 3, frame 1, main rotating shaft 4, fixed seat 2, vertical shaft 5, first mechanical arm 7, second mechanical arm 6, first mechanical claw 71 and second mechanical claw 61;

[0026] The first mechanical claw 71 is fixed on one end of the first mechanical arm 7, and the second mechanical claw 61 is fixed on one end of the second mechanical arm 6; the other end of the first mechanical arm 7 and the other end of the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com