Sedan tubular V-shaped torsion beam stamping process

A torsion beam and tubular technology, which is applied in the production of tubular V-shaped torsion beams for cars, can solve the problems of reducing the strength and service life of tubular V-shaped torsion beams, and easily producing convex hulls, etc., achieving low production costs, simple processes, and guaranteed rigidity and the effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

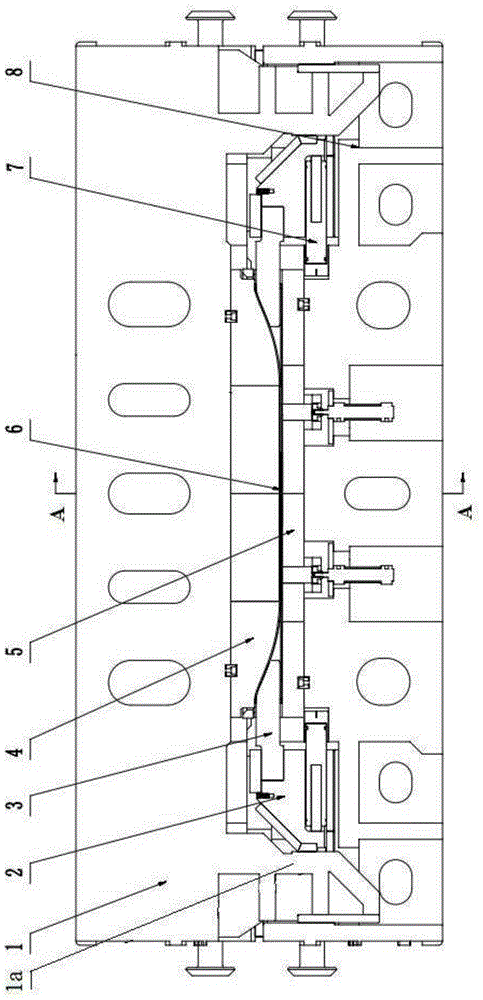

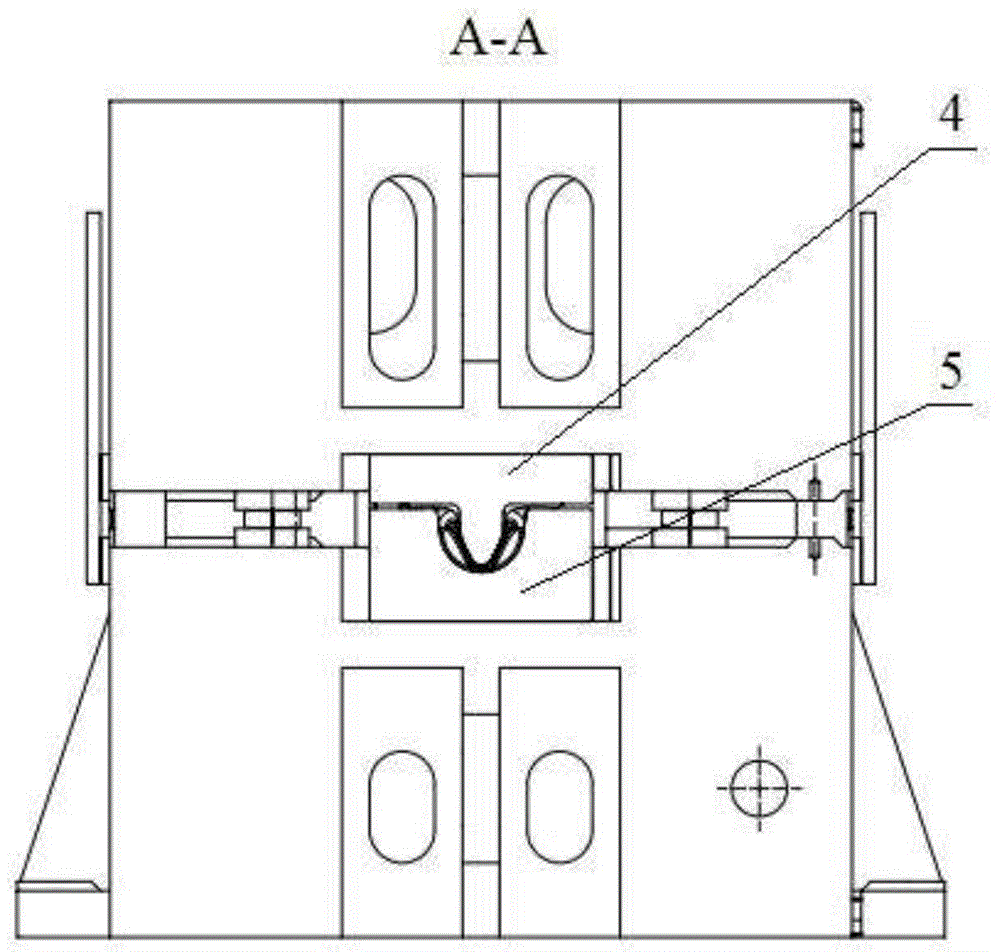

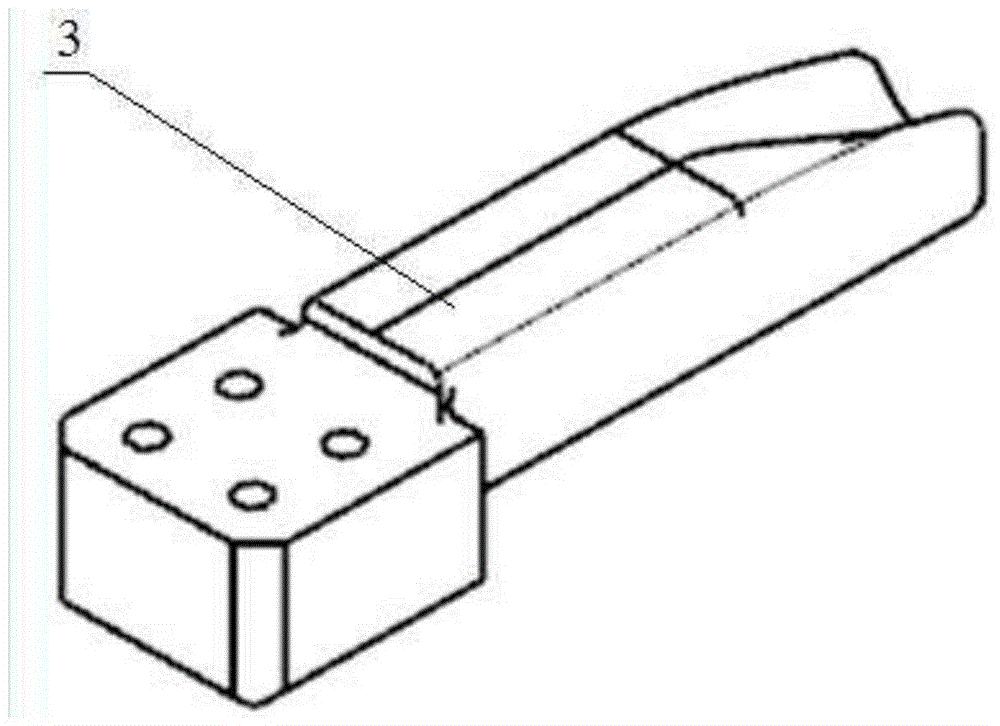

[0030] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 As shown, the present invention includes an inner V-shaped forming mold, an outer V-shaped forming port expansion mold, a port expansion mold, a first mandrel 3 , a second mandrel 12 and a third mandrel 24 . Car tubular V-shaped torsion beam stamping process of the present invention comprises the following steps:

[0031] The first step is to cut a circular tubular blank with a length of D=d+d', wherein d is the length of the tubular V-shaped torsion beam of a car to be produced, and said d'≥8mm. In this embodiment, preferably, d'=10mm, and the outer diameter of the blank is 89.7mm.

[0032] The second step is forming the inner V shape, inserting the first mandrel 3 at both ends of the blank, and putting the blank in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com