Design method of single-vane stamping type non-clogging impeller

A design method, stamping technology, applied in mechanical equipment, non-variable-capacity pumps, components of pumping devices for elastic fluids, etc., to achieve good non-clogging performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

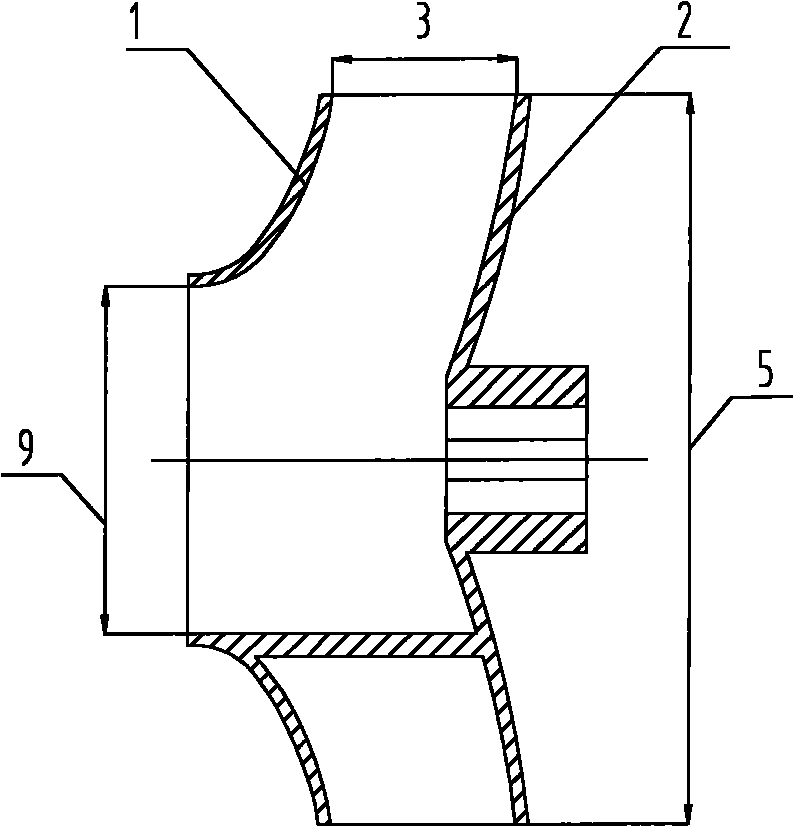

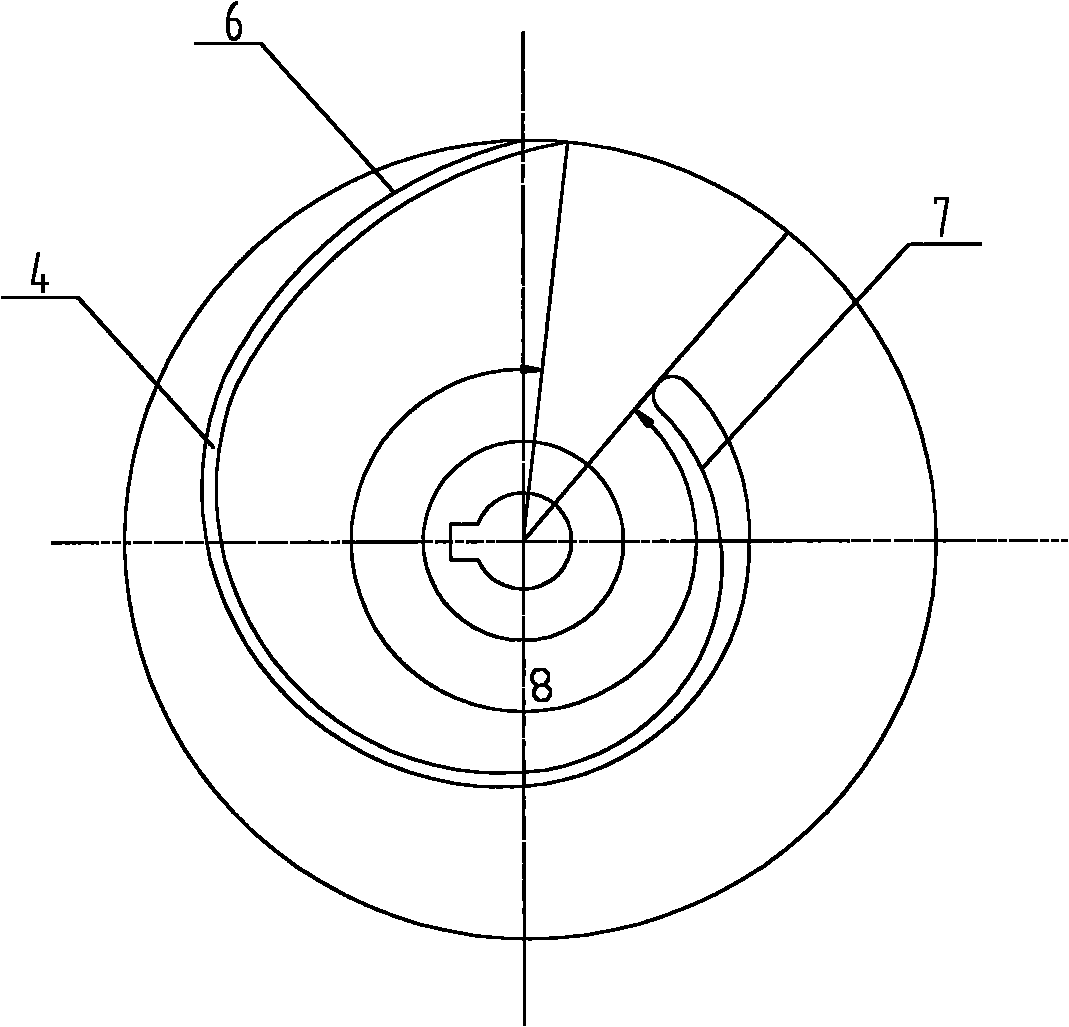

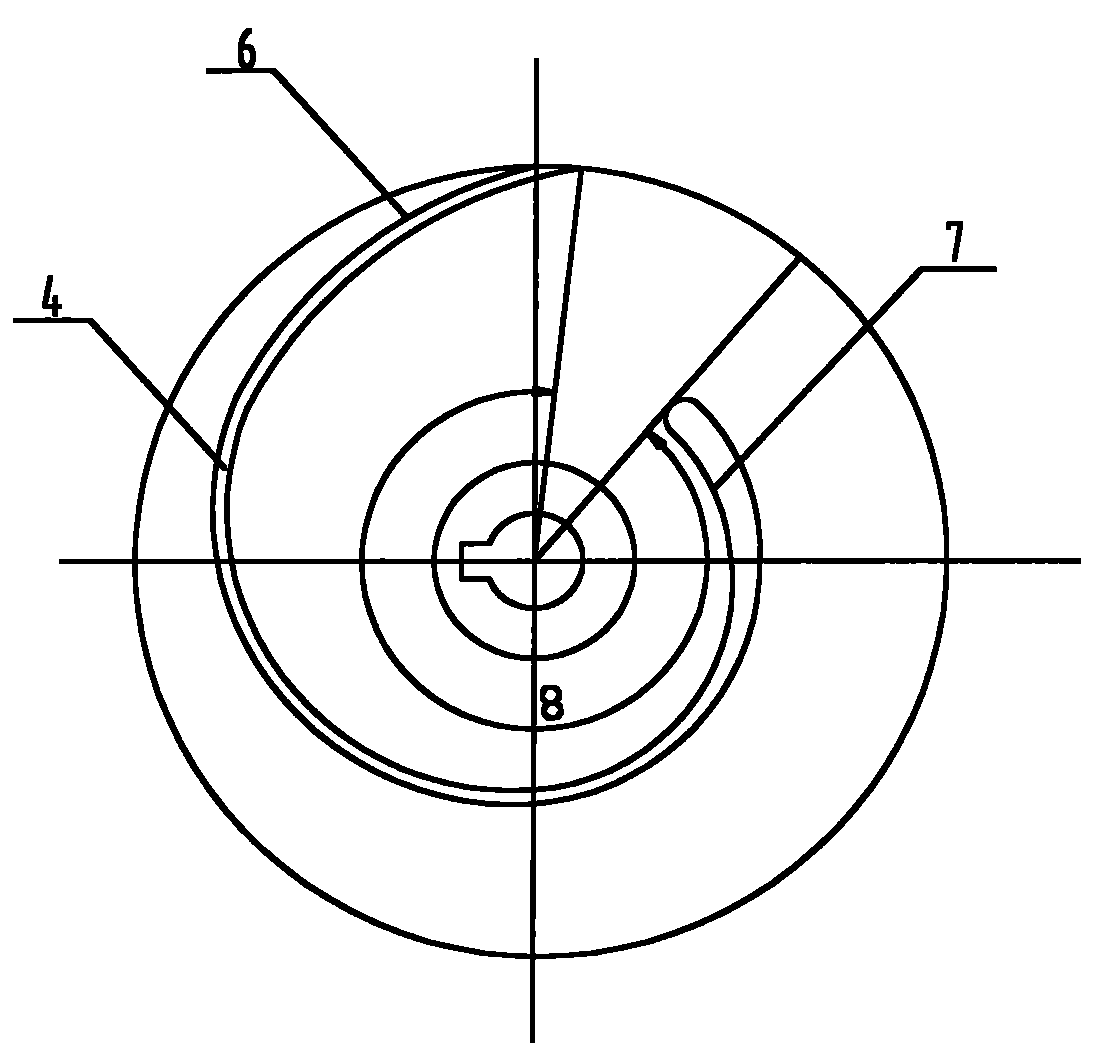

[0030] figure 1 and figure 2 Together determine the impeller shape for this embodiment. Like most single-blade non-clogging impellers, it has an impeller front cover (1) and an impeller rear cover (2), which is a closed impeller. If there is no impeller front cover plate and impeller rear cover plate very little, promptly make semi-open impeller and open impeller, also do not influence enforcement of the present invention. In the figure, the convex surface of the blade (4) is the blade working surface (6), the concave surface of the blade (4) is the blade back (7), the impeller inlet diameter (9) in the present embodiment, the impeller outlet width (3), The outer diameter of the impeller (5) is obtained according to the following relational formula.

[0031] Impeller inlet diameter D 0 The calculation formula is: D 0 = K 0 (Q / n) 1 / 3 K 0 =3.5~4.0

[0032] Impeller outer diameter D 2 The calculation formula is: D 2 = ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com