Hot stamping and superplastic gas-bulging combined forming process

A technology of superplastic forming and hot stamping, which is applied in transportation, packaging, and vehicle parts, etc., can solve the problems of delay in the weight reduction of aluminum alloy automobile bodies, inability to quench near-thirst in distant water, etc., to avoid cracking and Large springback, reduced material cost, less process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] From a commercial 5000 series aluminum alloy sheet, an automotive front fender was formed. The specific working steps are as follows:

[0024] 1) Obtain high-temperature stress-strain data and elongation data and forming limit diagrams of specific aluminum alloy sheets at different temperatures and different strain rates.

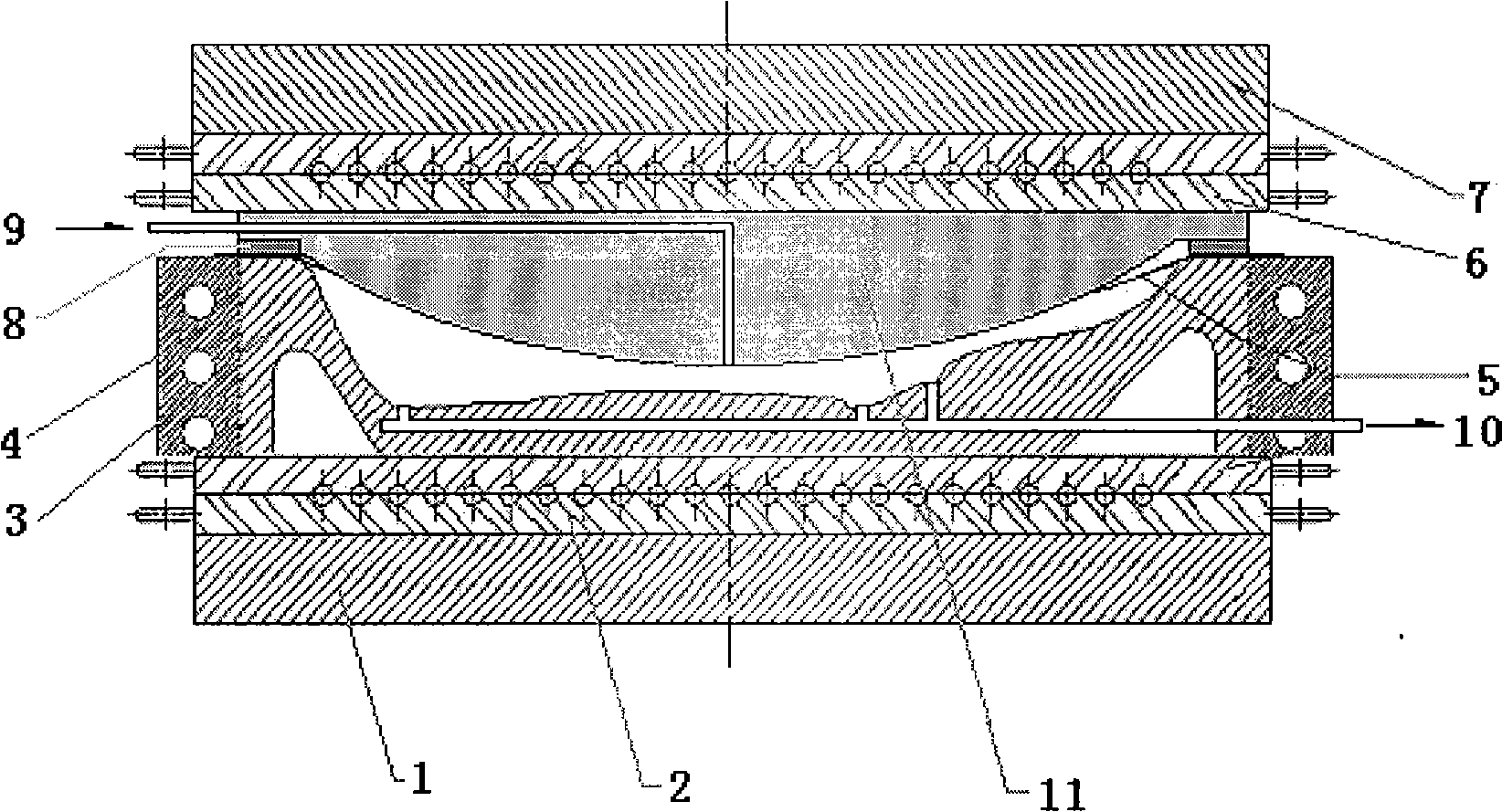

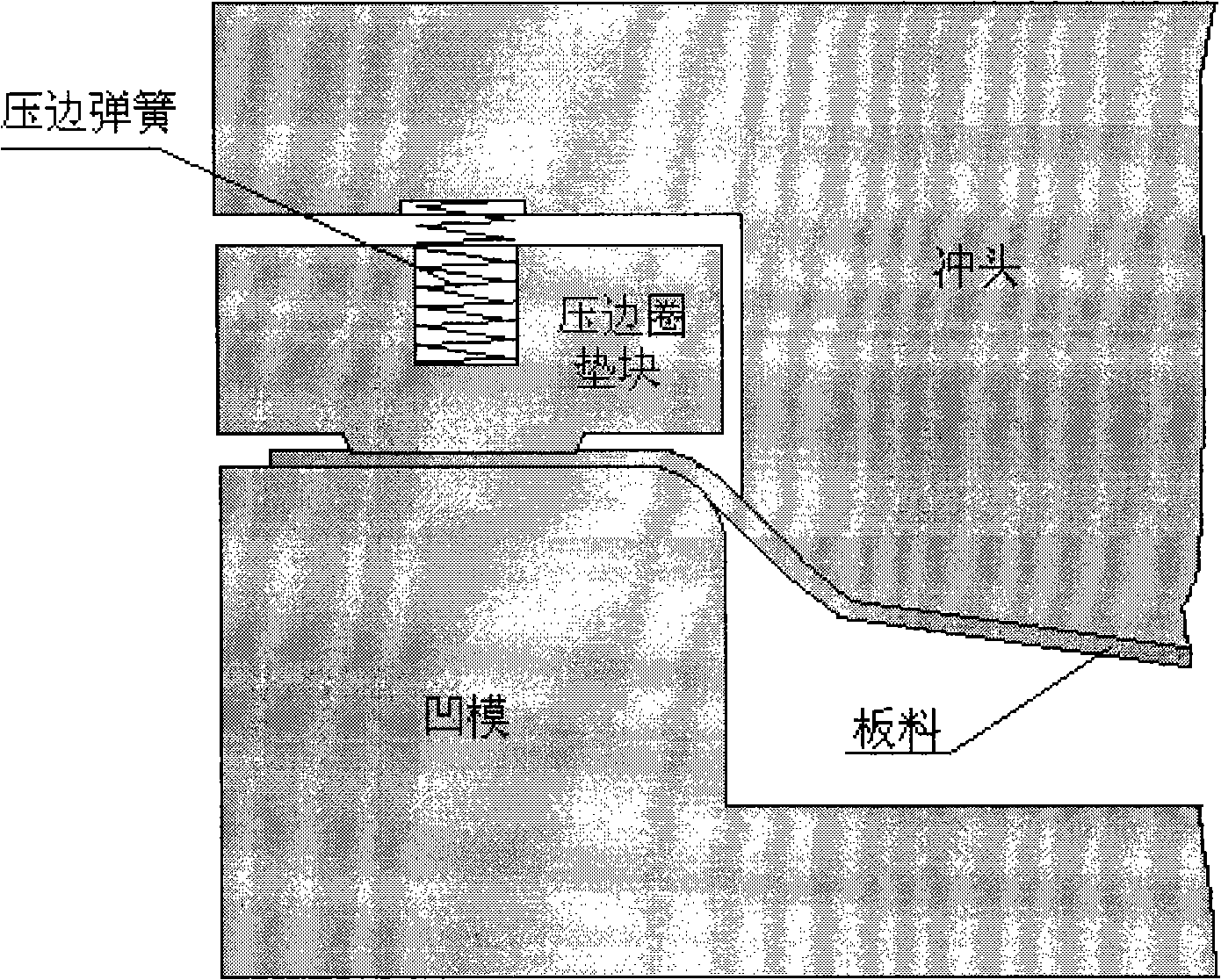

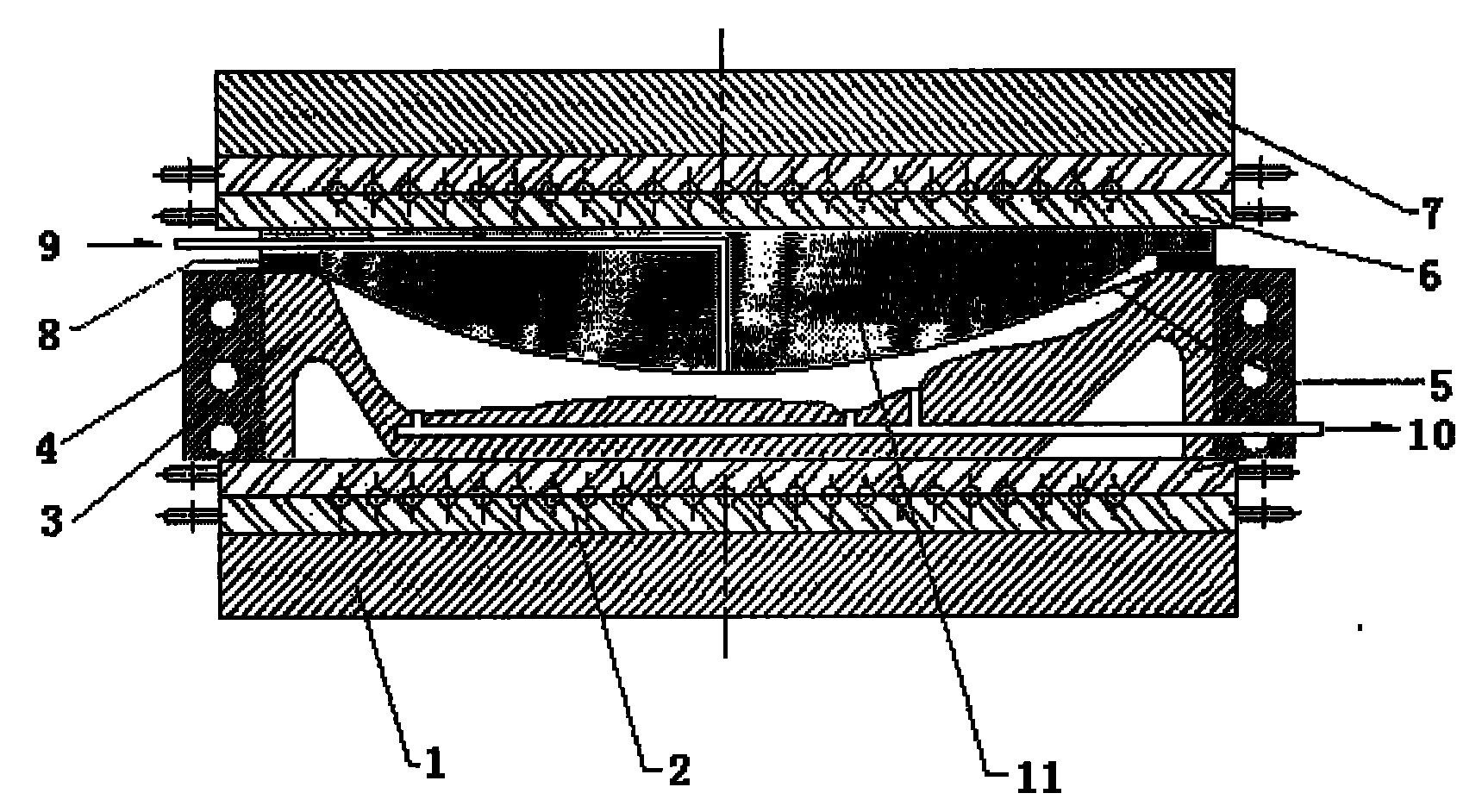

[0025] 2) Preliminary mold cavity surface design and process parameters (forming temperature, bulging gas pressure time curve) design are carried out according to the shape and size of the part to be formed.

[0026] 3) Apply numerical simulation technology to optimize the surface of the mold cavity to minimize the local strain, and optimize as much as possible to allow the maximum strain to appear in unimportant parts.

[0027] 4) Apply numerical simulation technology to optimize the forming temperature and pressure time curves to obtain the lowest cost and fastest forming speed, and accordingly select the appropriate grade of aluminum alloy sheet....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com