Transfer inkjet printer device

An inkjet printing device and transfer printing technology, which is applied to inking devices, ink transfer from original manuscripts, printing, etc., can solve the problems of inability to form printed images, and achieve the effect of less uneven depth and excellent durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

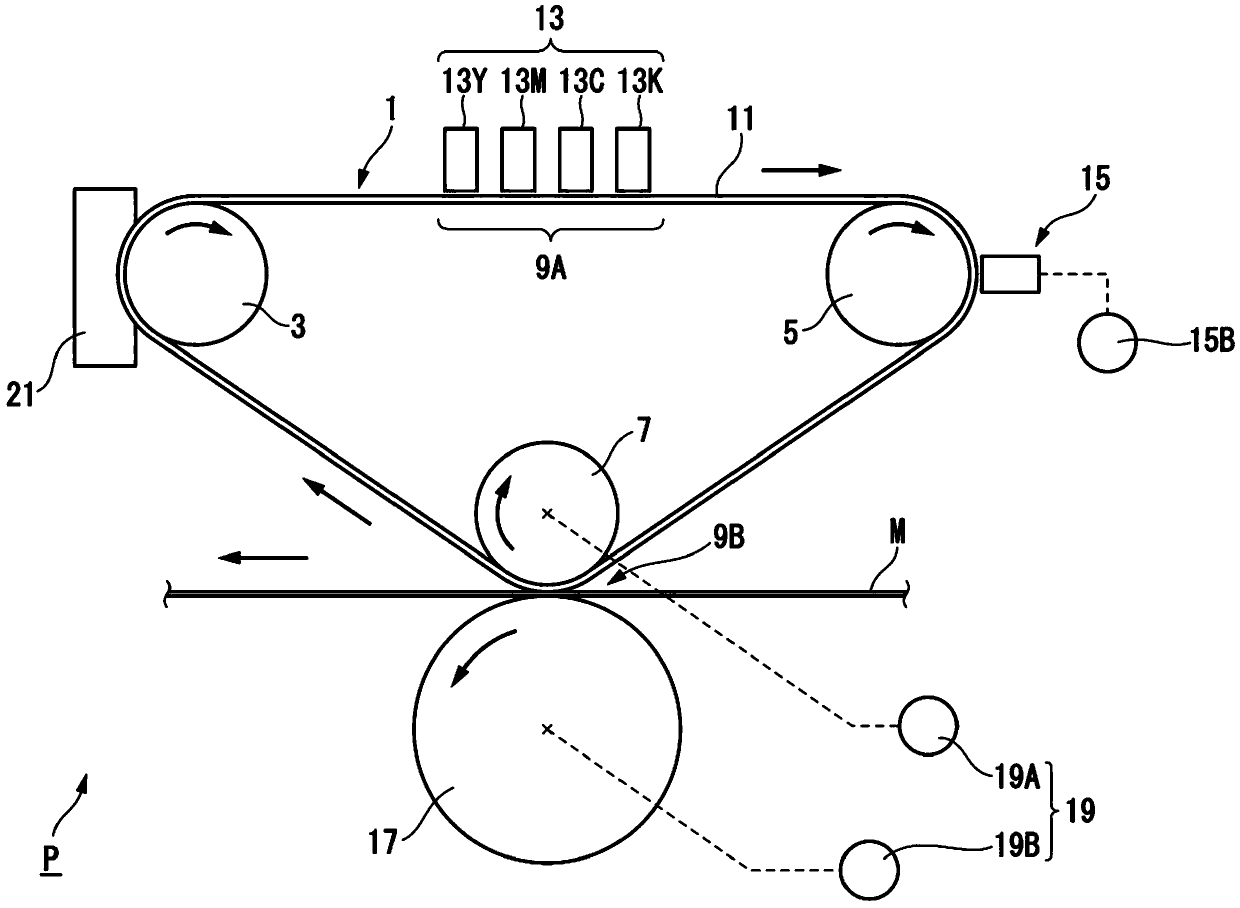

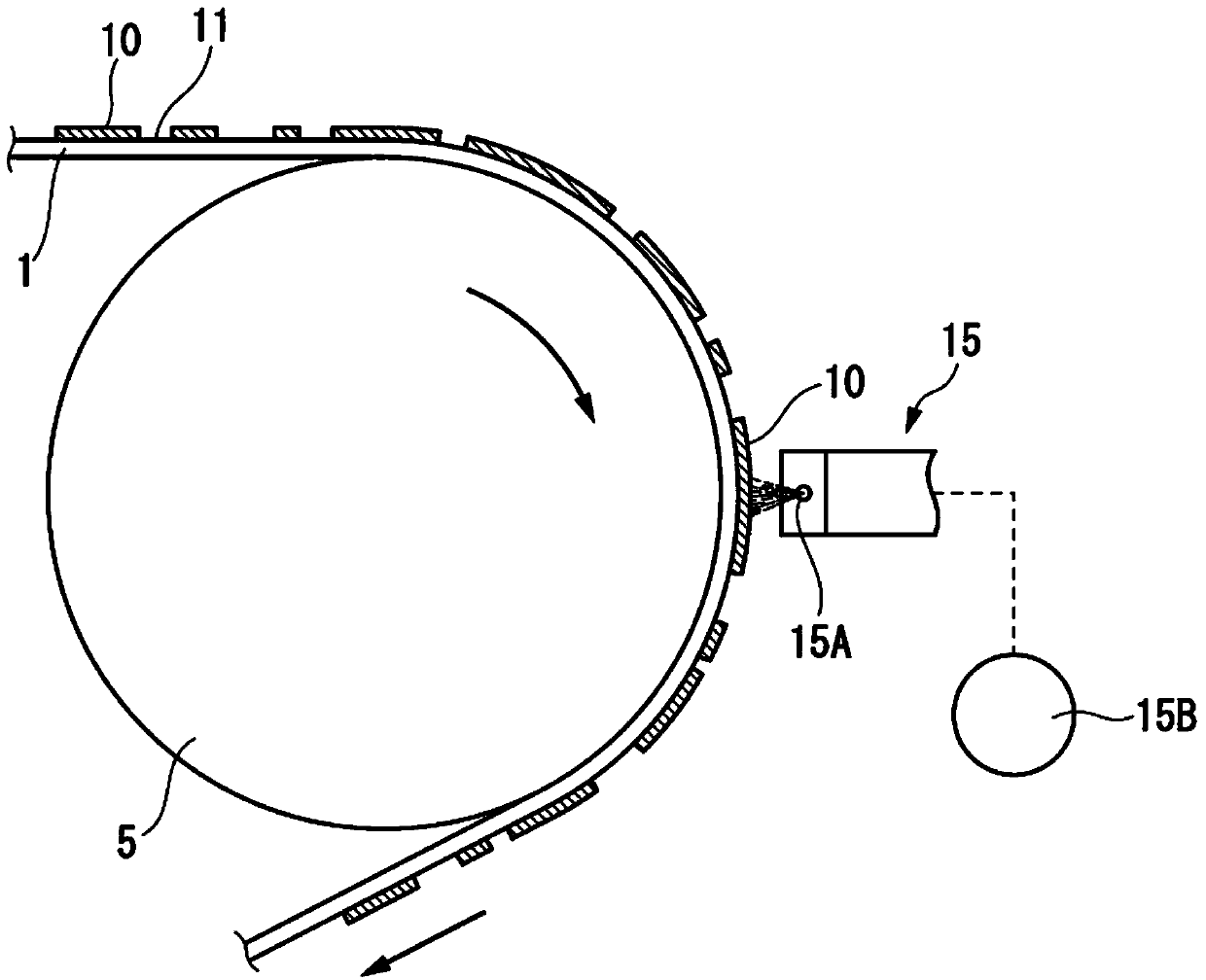

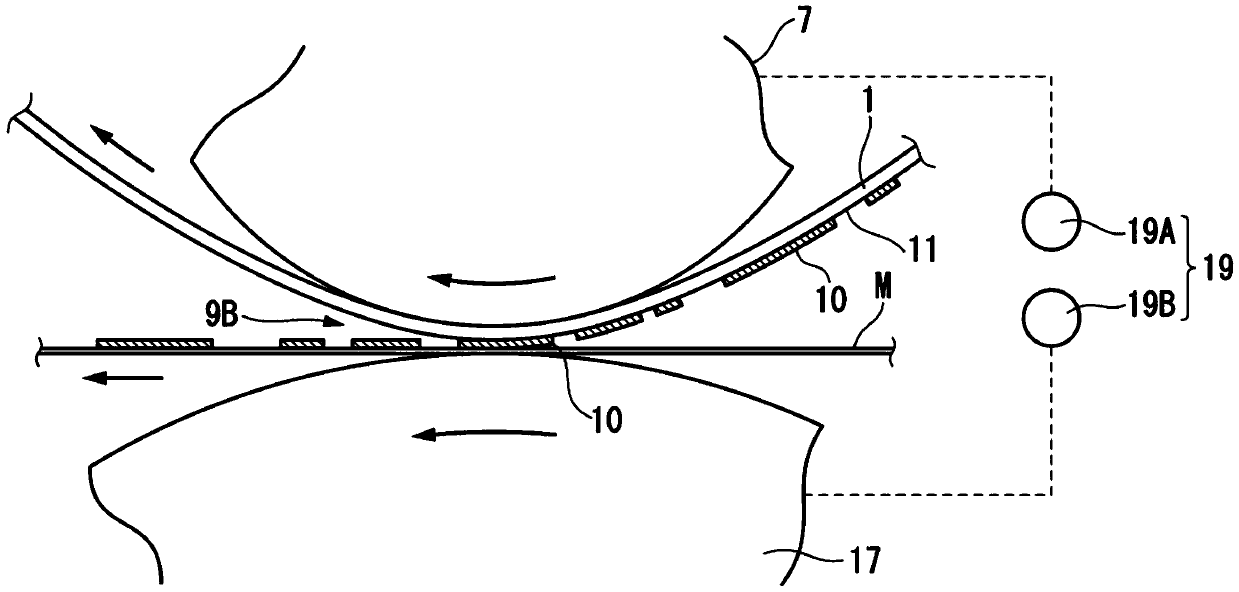

[0021] Hereinafter, the transfer type inkjet printing device of the present invention will be described in detail with reference to the accompanying drawings.

[0022] Figure 1 to Figure 3 A transfer type inkjet printing apparatus P according to the first embodiment of the present invention is shown, which utilizes a transfer belt 1 as an intermediate transfer body, and prints on a recording medium M such as cardboard, cardboard, resin sheet, or cloth as an object to be printed. Printed images such as images and text are formed on the surface. Figure 1 to Figure 3 The up and down direction on the paper is the same as the vertical direction of the device.

[0023] The transfer type inkjet printing device P includes: a transfer belt 1 (intermediate transfer body); a first guide roller 3; a second guide roller 5; a backup roller 7 (pressurizing mechanism); an inkjet head 13; ; Pressing roller 17 (pressing mechanism); Electric field applying mechanism 19 ; Cleaning device 21 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com