Anode tank, crude foil engine and method for producing electrolytic copper foil through electrolyte flowing

An anode cell and electrolyte technology, applied in electrolytic components, electrolytic process, electroforming, etc., can solve the problems of uneven thickness of copper foil, excessive Reynolds number of liquid inlet, and no research, so as to reduce copper foil non-uniformity. Uniformity, the uniformity of copper foil thickness, and the effect of ensuring the deposition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

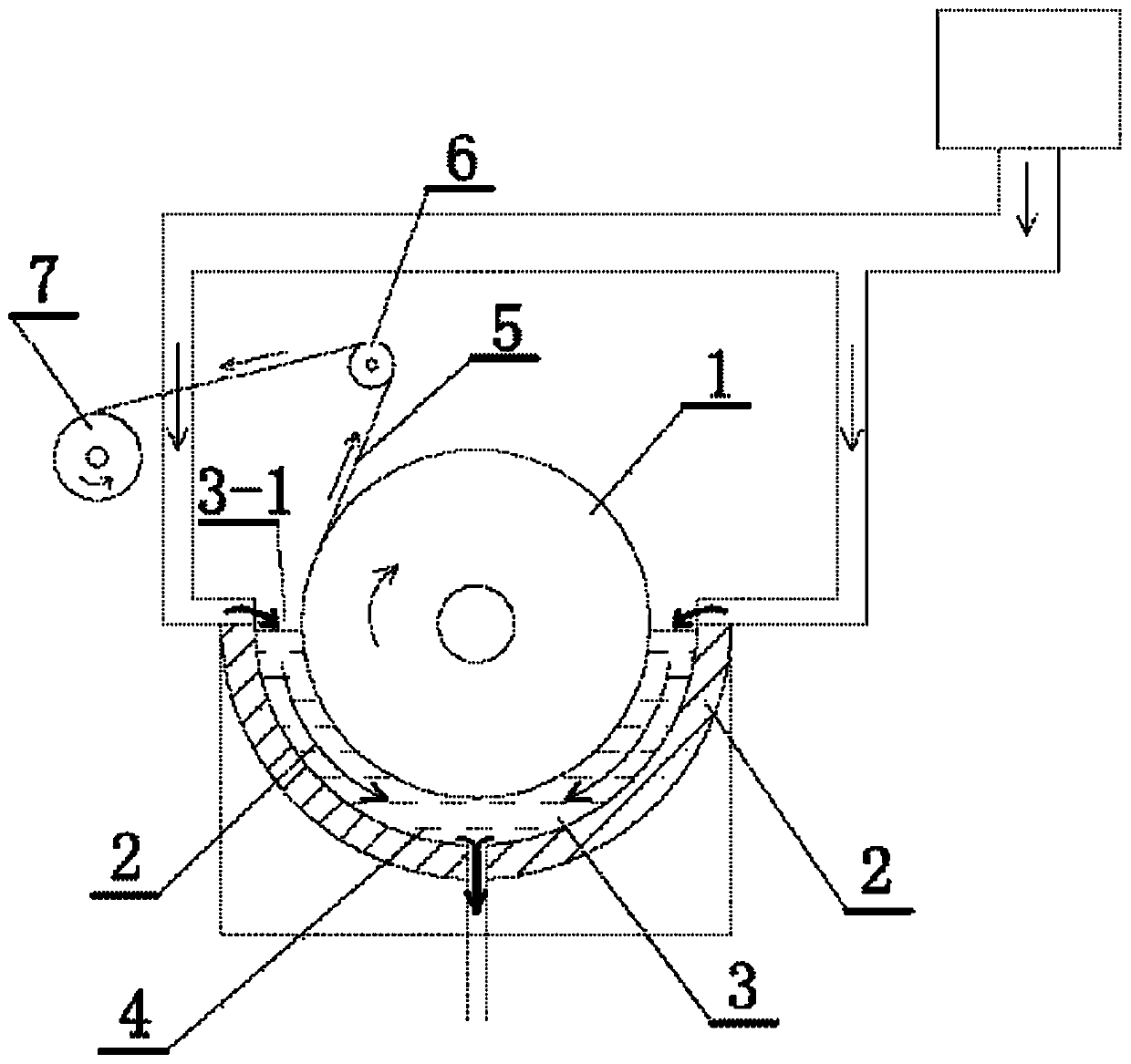

[0101] Example 1, such as Figure 5-7 Shown:

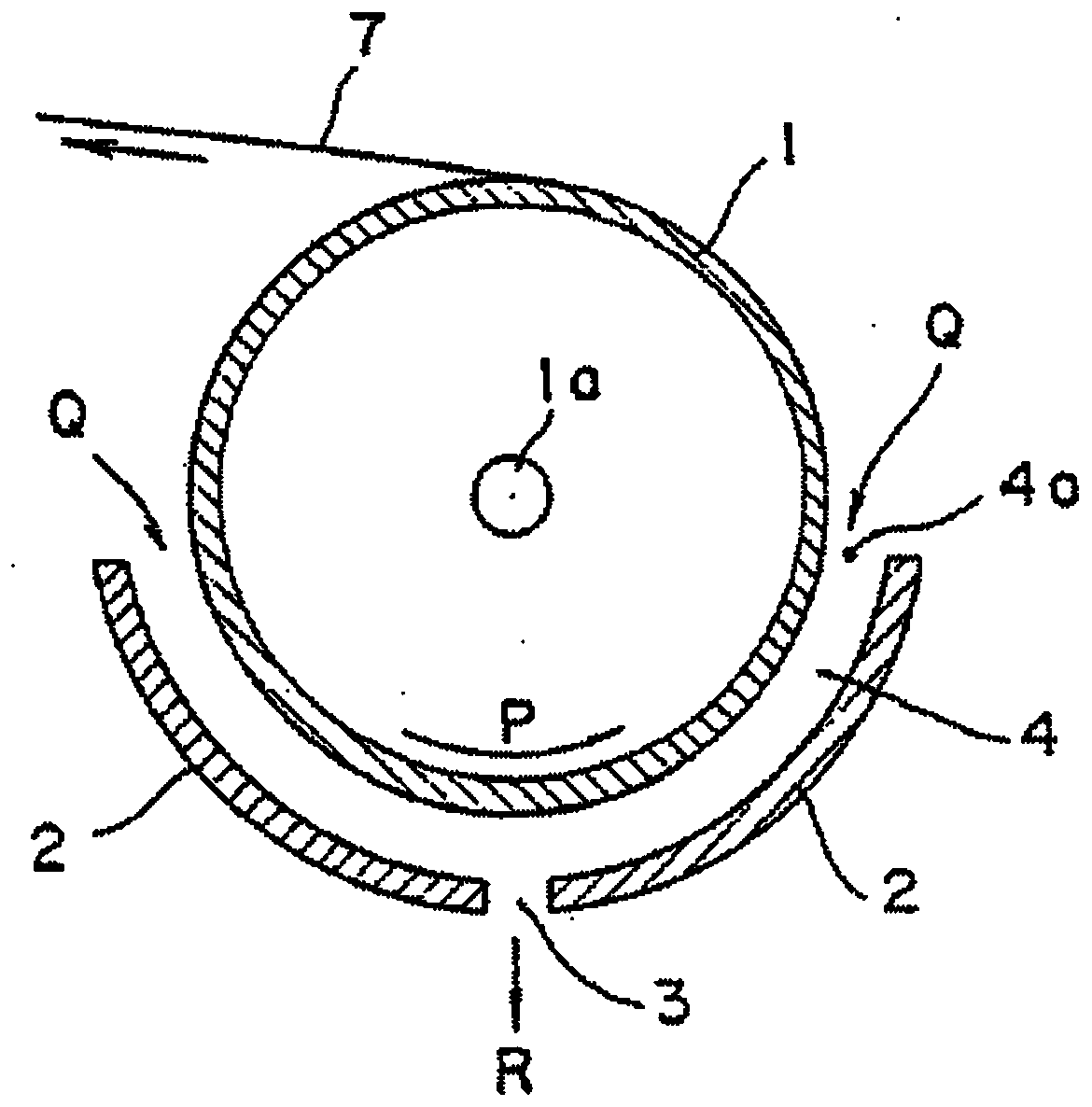

[0102] A foil production machine, comprising: an anode tank 1, a cathode roller 2, and an electrolyte adding pipeline 3;

[0103] The anode tank 1 is a hollow structure, and the anode tank 1 includes: an anode plate 1-1 on one side of the cathode roller, a fixing plate 1-2 on the side away from the cathode roller, and a lateral fixing plate;

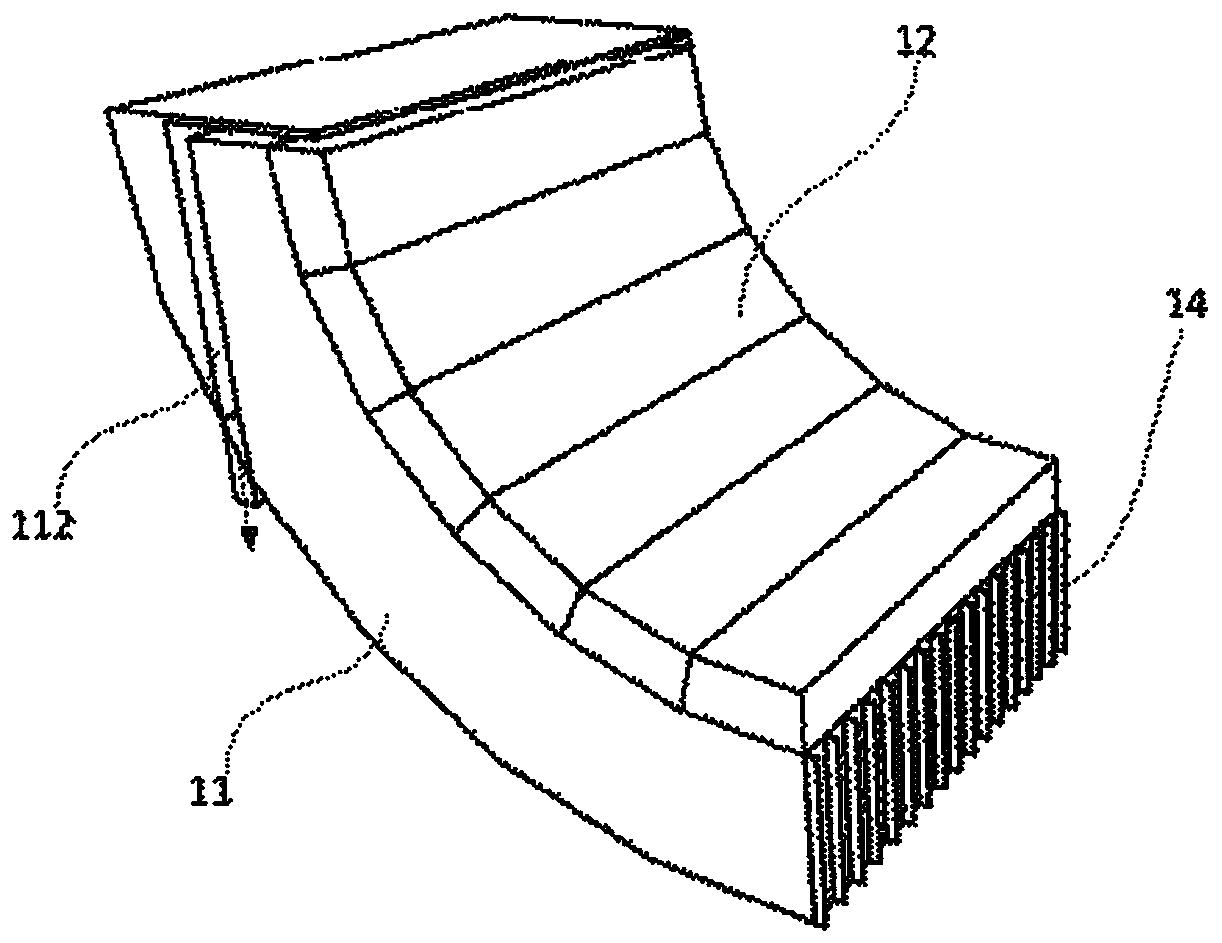

[0104] The anode plate 1-1 is composed of a plurality of anode veneers 1-1-1, and the plurality of anode veneers form an arc-shaped anode plate;

[0105] Wherein, two adjacent anode veneers are provided with corresponding recesses 1-1-2 on their respective adjacent edges;

[0106] The recess of the anode veneer and the corresponding recess of the adjacent anode veneer form an opening;

[0107] The electrolyte pipeline 3 includes: a main pipeline and a plurality of branch pipelines, the main pipeline is connected with the branch pipelines, the main pipeline of the electrolyte pipeline 3 pe...

Embodiment 1

[0110] The advantage of Embodiment 1 is: the branch pipeline protrudes from the surface of the anode plate of the anode tank, and several branch pipes are evenly distributed on the entire surface of the anode tank, and the liquid inlet of the electrolyte is a branch pipe; it makes the copper ions flow along the cathode The concentration in the direction of rotation of the roller remains basically unchanged (the supplement of copper ions does not need to go through a long path, but directly reaches the vicinity of the cathode roller), which ensures the deposition effect of the copper foil and reduces the occurrence of uneven copper foil (this application It is not through additives to improve the unevenness of copper foil).

Embodiment 2

[0111] Embodiment 2: as Figure 5 The design (embodiment 1) is also the upper liquid return port, and the upper liquid return port will face the problem of rising acid gas.

[0112] To this end, the improvements are as follows:

[0113] Such as Figure 8 Shown: Non-immersed anode cell:

[0114] A sealing roller 4 (height lower than the height of the peeling roller) is arranged at the upper port of the foil outlet side of the anode tank;

[0115] It also includes: an upper plate 5-1, a lower plate 5-2, and two side plates; the sealing roller 4 is arranged above the anode tank and is in contact with the cathode roller 2, and the length of the sealing roller 4 is the same as that of the cathode The length of the roller 2 is adapted; the sealing roller 4 is hinged on the upper plate 5-1;

[0116] The lower plate 5-2 is arranged outside the upper port of the anode tank;

[0117] The upper plate 5-1, the lower plate 5-2, and two side plates form an electrolyte pipeline (for ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com