Thin-film LED substrate for printing, printed thin-film LED device, and preparation method thereof

An LED device and printing technology are applied in the field of printing thin-film LED substrates, printing thin-film LED devices and their preparation fields, and can solve the problems of cumbersome preparation process, unfavorable LED functional layer ink printing, complex groove substrate structure, etc. , to achieve the effect of high design flexibility, simplified process complexity and high resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

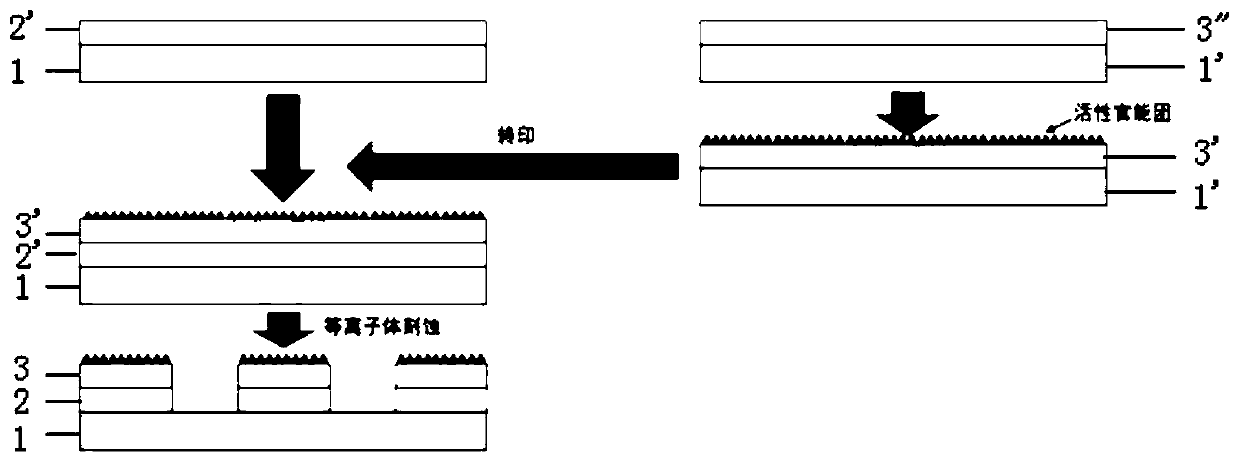

[0033] Correspondingly, combine figure 1 , as an implementation situation, an embodiment of the present invention provides a method for preparing a thin film LED substrate for printing, including the following steps:

[0034] S01. provide first substrate 1 and second substrate 1 ', deposit first graphene layer 2 ', second graphene layer 3 " on described first substrate 1, second substrate 1 ' respectively;

[0035] S02. After the second graphene layer 3 "is subjected to surface modification treatment, it is transferred to the surface of the first graphene layer 2' to form a composite graphene layer;

[0036] S03. According to the preset pixel array of the printed thin-film LED device, the composite graphene layer is patterned to form a patterned composite layer to obtain a thin-film LED substrate for printing.

[0037] Specifically, in the above step S01, the selection of the first substrate 1 and the second substrate 1' is not strictly selected. For details, refer to the abo...

Embodiment 1

[0072] A method for preparing a printed QLED device, comprising the following steps:

[0073] E11. Prepare QLED substrate for printing, including

[0074] E111. Depositing a first graphene layer on the first substrate by CVD, and depositing a second graphene layer on the second substrate;

[0075] E112. Utilizing concentrated sulfuric acid to carry out surface modification treatment on the second graphene layer, introducing active functional groups; transferring the second graphene layer after the surface modification treatment to the surface of the first graphene layer to form composite graphite vinyl layer;

[0076] E113. Plasma etching the composite graphene layer to form a patterned composite layer to obtain a QLED substrate for printing.

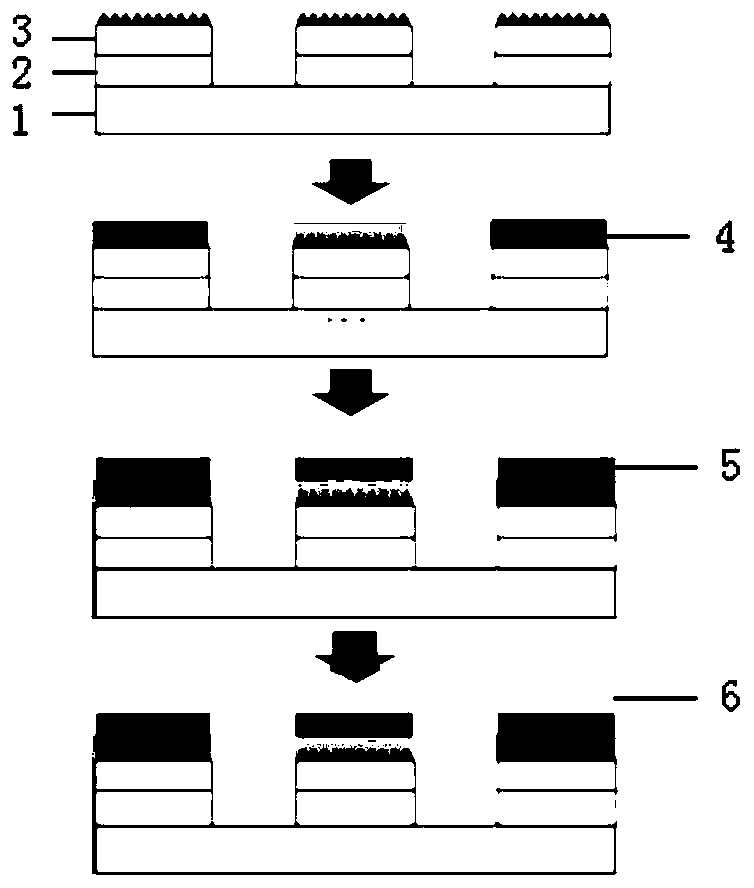

[0077] E12. Printing a CdSe / ZnS quantum dot light-emitting layer and a ZnO electron transport layer sequentially on the patterned composite layer in the QLED substrate for printing, and depositing an Al cathode to obtain a printed QLE...

Embodiment 2

[0079] A method for preparing a printed OLED device, comprising the following steps:

[0080] E21. Preparation of OLED substrate for printing, including

[0081] E211. Depositing a first graphene layer on the first substrate by CVD method, and depositing a second graphene layer on the second substrate;

[0082] E212. Using concentrated sulfuric acid to carry out surface modification treatment on the second graphene layer to introduce active functional groups; transfer the surface modification treatment of the second graphene layer to the surface of the first graphene layer to form composite graphite vinyl layer;

[0083] E213. Plasma etching the composite graphene layer to form a patterned composite layer to obtain an OLED substrate for printing.

[0084] E22. Printing the light-emitting layer / electron transport layer sequentially in the groove area of the OLED substrate for printing, and depositing the Al cathode to obtain a printed OLED device.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron work function | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com