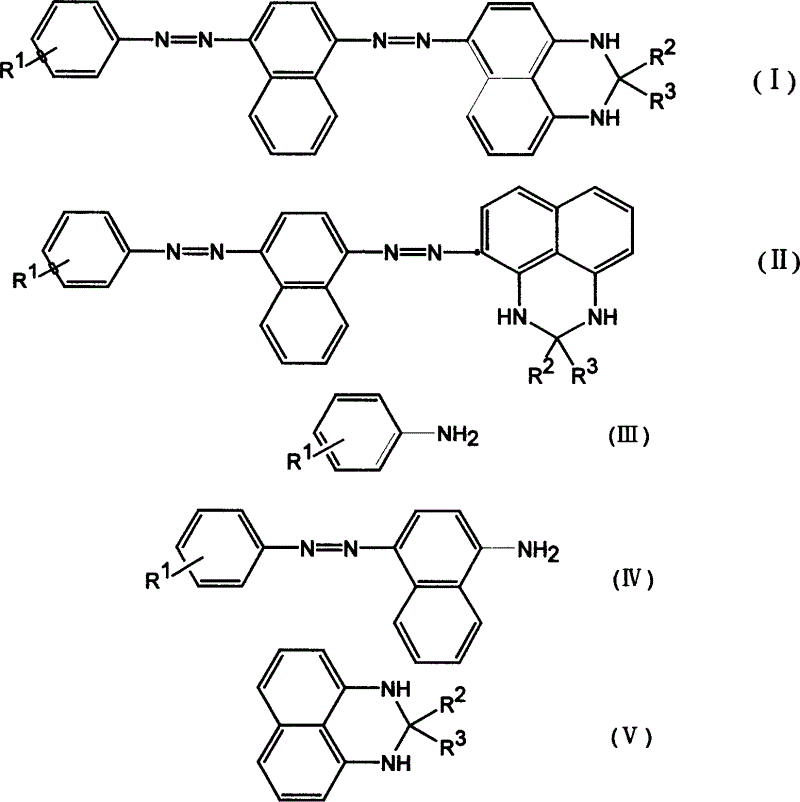

Bisazo solvent dye preparation method and uses

A solvent dye and disazo technology, which is applied in the field of preparation of disazo solvent dyes, can solve the problem of not being able to meet the requirements of inkjet applications, and achieve the effect of good stable solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

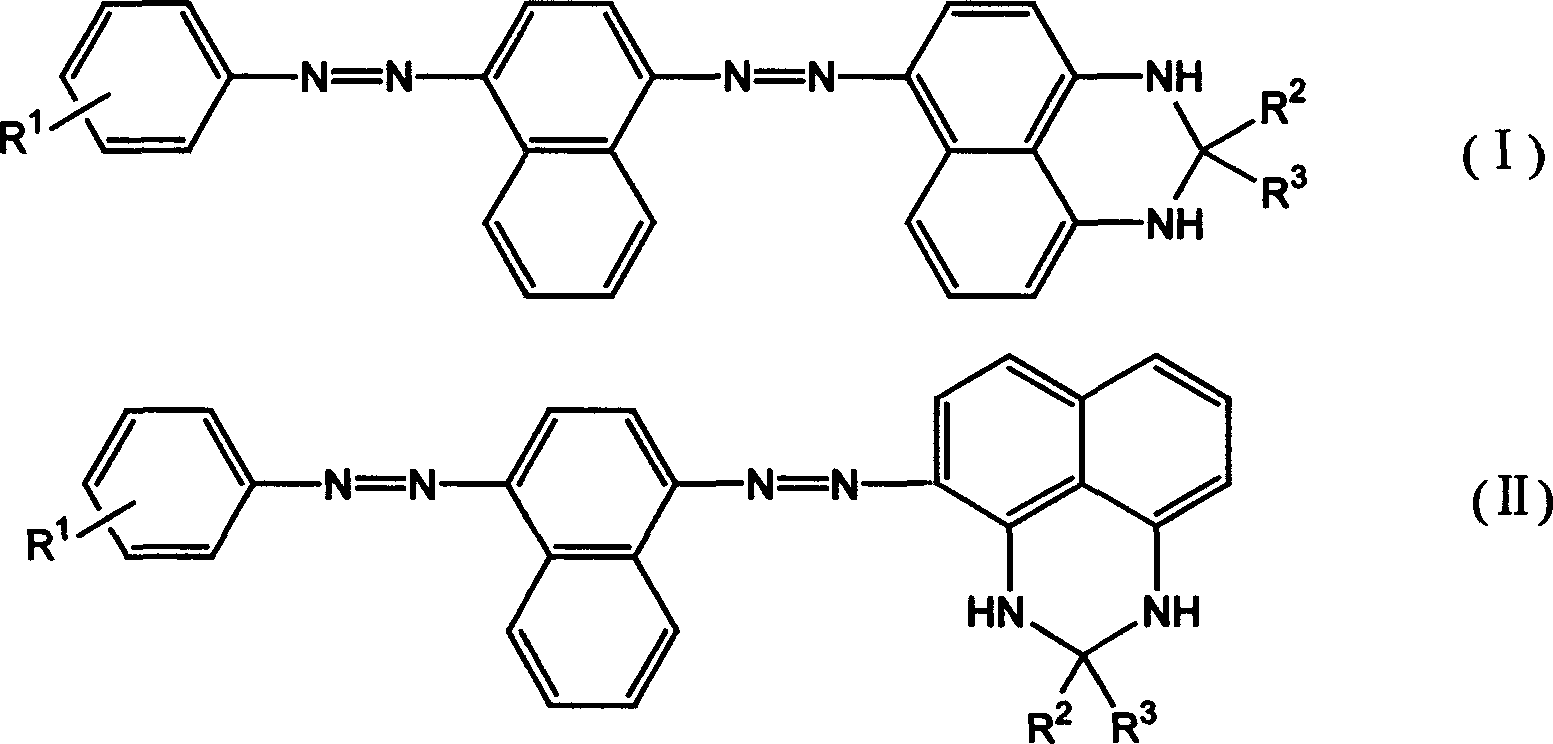

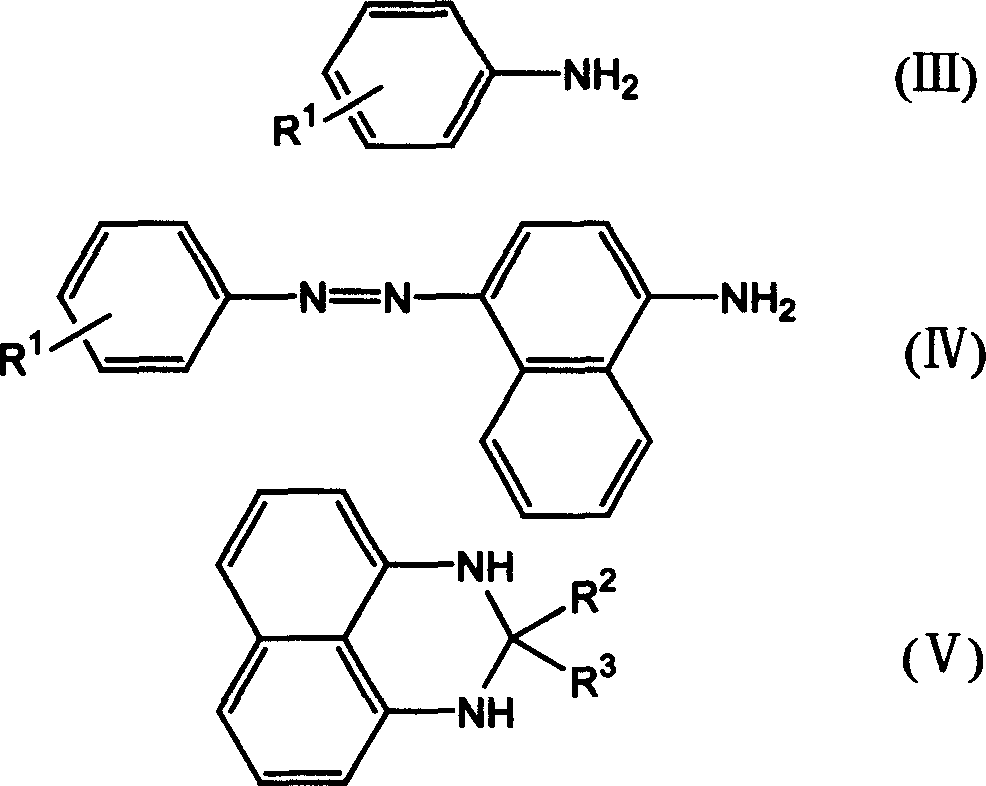

[0021] 9.35 parts III(R 1 =H) Mix with 130 parts of water and 25 parts of concentrated hydrochloric acid, cool to 0°C with ice, add an aqueous solution containing 7.2 parts of sodium nitrite, and stir at 0-5°C for 1 hour.

[0022] Stir the mixture containing 15 parts of 1-naphthylamine, 300 parts of water and 12 parts of hydrochloric acid to 70-80°C until all the materials are dissolved. Then add ice and cool down to 20-30°C. Then add 21 parts of sodium acetate. Then add the diazonium reaction solution of III prepared above, and stir at about 10°C until the coupling reaction is completed. Then add 20-25% NaOH solution to adjust the reaction solution to make the phenolphthalein test paper change color. Filter and wash with water until neutral. A red IV wet cake was obtained. Purity by HPLC analysis was 85%.

[0023] After drying the wet cake of IV, add 120 parts of ethanol, stir at reflux temperature for 1 hour, cool down to 20-25°C, and filter. Add 400 parts of water to...

Embodiment 2

[0030] According to the method of embodiment 1, use R in the preparation of V 2 -CO-R 3 (R 2 =CH 3 , R 3 =CH 2 CH 3 ) is condensed with 1,8-diaminonaphthalene. The diazonium solution of IV and the acidic solution of V were mixed and stirred at 20°C for 0.5 hours until the reaction was complete. Preparation of I and II (R 1 = H, R 2 =CH 3 , R 3 =CH 2 CH 3 ) 43.8 parts of mixed solvent dyes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com