Preparation method of pyrene ketone solvent dye

A solvent dye, renone type technology, applied in the green preparation field of renone type solvent dye, can solve the problems of large amount of waste water, equipment corrosion, not belonging to green process, etc., and achieves the effect of high cost performance and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

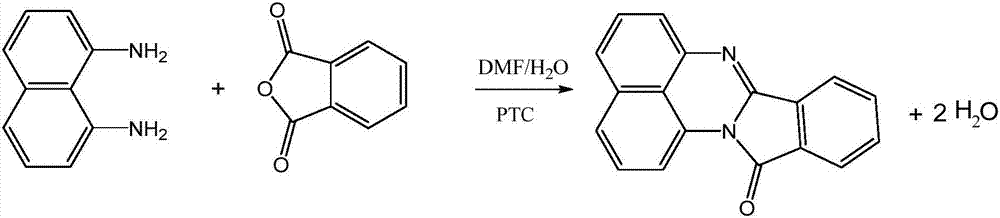

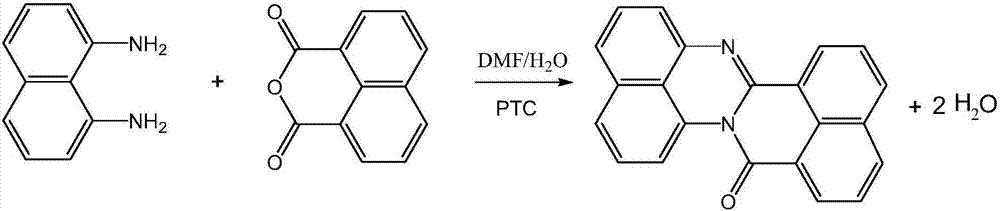

Method used

Image

Examples

Embodiment 1

[0035] In a 250ml four-neck flask, nitrogen gas was introduced, 230g of 80% DMF aqueous solution was added, and 0.8g of sodium sulfite, 15.8g (0.1mol) of 1,8-diaminonaphthalene, and 15.1g (0.102 mol), 0.6g PEG-400. Raise the temperature to micro-reflux (about 108-115°C) and keep it warm for 10 hours. Take a sample to detect the end point. After the end point is reached, cool down to room temperature and filter. The filter cake is soaked twice with 50g 30% DMF, drained, and then washed with 25g 60% DMF. Soak in hot water at about ℃ and drain, and combine the filtrates for recovery. The filter cake is washed with hot water at about 60°C until the color does not fade, and then dried at 105°C. 25.9 g of bright orange solvent orange 60 crystals were obtained (yield 95.9%), and the shade and intensity were ΔC 0.14, ΔE 0.42, and intensity 99.8% compared with the standard product.

[0036]Recovery of DMF: In a 500ml four-neck flask equipped with a thermometer, packed column, condens...

Embodiment 2

[0038] Replace "PEG-400" with "PEG-600", and the rest are the same as in Example 1. 25.7 g of bright orange solvent orange 60 crystals were obtained (yield 95.2%), compared with the standard product, ΔC 0.24, ΔE 0.46, and intensity 100.9%.

[0039] The DMF recovery process is the same as in Example 1, and the DMF recovery rate is 92.1%.

Embodiment 3

[0041] In a 500ml four-neck flask, blow nitrogen gas, add 270g of 70% DMF aqueous solution, add 0.65g of sodium dithionite, 15.8g (0.1mol) of 1,8-diaminonaphthalene, and 15.1g of phthalic anhydride under stirring (0.102 mol), 0.8 g PEG-400. Raise the temperature to micro-reflux (about 105-112°C) and keep it warm for 12 hours, take a sample to detect the end point, after the end point is reached, cool down to room temperature, filter, soak the filter cake twice with 50g of 20% DMF, and then heat it with 25g of 60°C or so Wash once with water, drain, and combine the filtrates for recovery. The filter cake is washed with hot water at about 60°C until the color does not fade, and then dried at 103°C. 25.4 g of bright orange solvent orange 60 crystals were obtained (yield 94.1%), compared with the standard product, ΔC 0.12, ΔE 0.35, and strength 99.6%.

[0042] Reclaim DMF: in 500ml flask, add DMF filtrate to be recovered, distill, collect 100~115 ℃ fraction 100g (DMF aqueous sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com