Anthraquinone type solvent dye and preparation and application thereof

A solvent dye, anthraquinone technology, applied in the field of dyes, can solve problems such as harming the environment, corroding equipment, wasting resources, etc., and achieving the effects of reducing air pollution, low cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

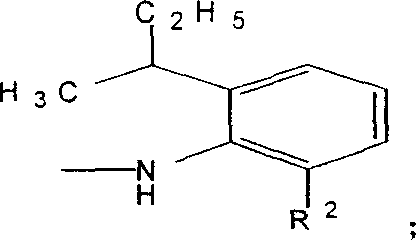

[0039] Example 1: Separation and purification of 2-ethyl-6-sec-butylaniline

[0040]Distillation: Add 600g of industrial waste oil produced in the production of DEA into a 1000ml three-necked flask, add zeolite, and pass nitrogen through the bottom pipe. Distillation conditions: rectification tower diameter 30mm, stainless steel triangular packing, packing height 1100mm, vacuum degree 10mmHg, reflux ratio 5:1. When the liquid phase temperature reaches 137°C, reflux occurs, and the fractions at 141-144°C are collected to obtain 300 g of the main fraction, which is 2-ethyl-6-sec-butylaniline, with a content of 95%.

example 2

[0041] Example 2: Separation and purification of 2-methyl-6-sec-butylaniline

[0042] Distillation: Add 600g of industrial waste oil produced in the production of MEA into a 1000ml three-necked flask, add zeolite, and introduce nitrogen through a bottom pipe. Distillation conditions: rectification tower diameter 30mm, stainless steel triangular packing, packing height 1100mm, vacuum degree 10mmHg, reflux ratio 5:1. When the liquidus temperature reaches 127°C, reflux occurs, and the 130-133°C fractions are collected to obtain 268g of the main fraction, which is 2-methyl-6-sec-butylaniline with a content of 93.5%.

example 3

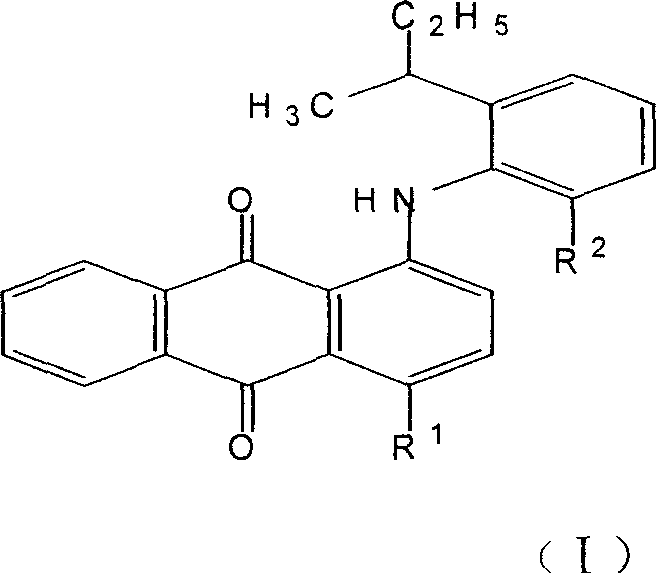

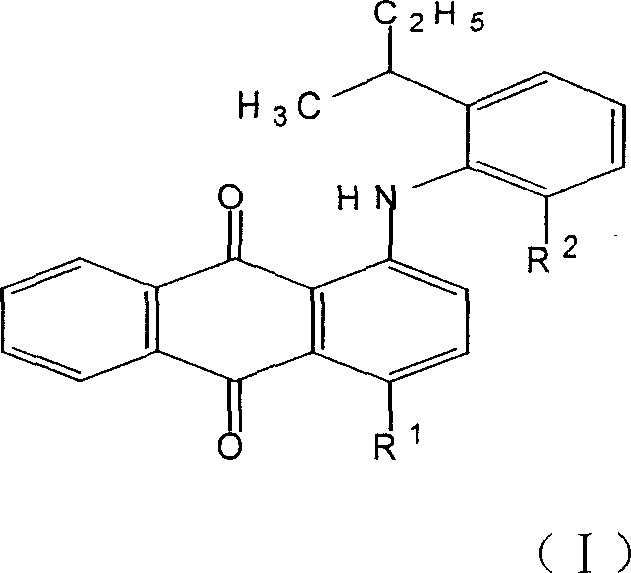

[0043] Example 3: Synthesis of Compound I

[0044] Add 7.0g 1,4-dihydroxyanthraquinone, 3.0g 1,4-dihydroxyanthraquinone leuco, 1.2g boric acid, 32g 2-ethyl-6-sec-butylaniline in a 100ml four-necked flask, Stir and raise the temperature to 150°C while removing the water brought in by the raw materials and the reaction generated. The reaction is controlled by thin-layer chromatography: when the yellow and orange raw material spots basically disappear, the reaction is considered to have reached the end point, the reaction is stopped, the temperature is reduced to 90°C, potassium hydroxide 5g is added, and air is oxidized until the purple disappears. , Which is the end point of oxidation, the reaction solution was slowly precipitated into 100 ml of hot ethanol, then cooled, filtered, and washed to obtain 16.1 g of compound I with a yield of 69.4%.

[0045] NMR data:

[0046] 1 H NMR(DCCI 3 ,300MHz)δ0.77-0.83(m, 3H, CH 3 ), 1.01-1.17(m, 6H, CH 3 ), 1.48-1.1.54(m, 2H, CH 2 ), 2.44-2.59(...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com