Red naphtocyclinon solvent dye and preparation method thereof

A technology of solvent dyes and naphthyrone, applied in dyeing methods, azo dyes, organic dyes, etc., can solve the problems of transparency and lack of toxic and harmful substances, and achieve the effects of easy operation, excellent heat resistance, and high yield

Inactive Publication Date: 2008-10-29

海宁市现代化工有限公司

View PDF0 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The current red solvent dyes are still insufficient in fastness, transparency and control indicators of toxic and harmful substances

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

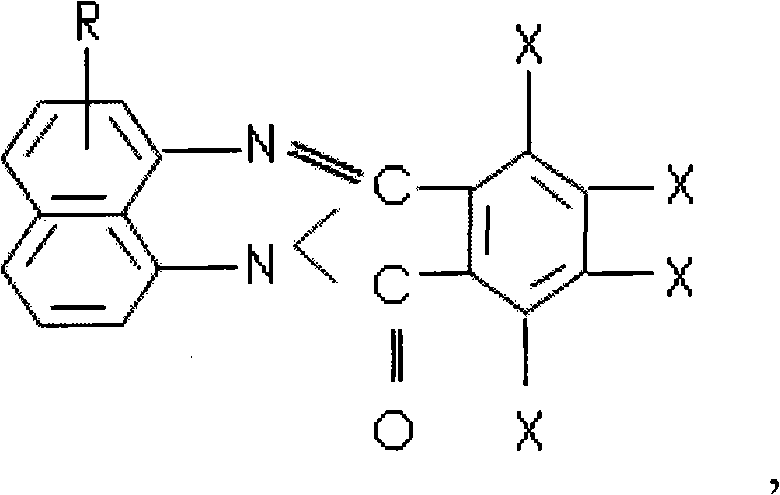

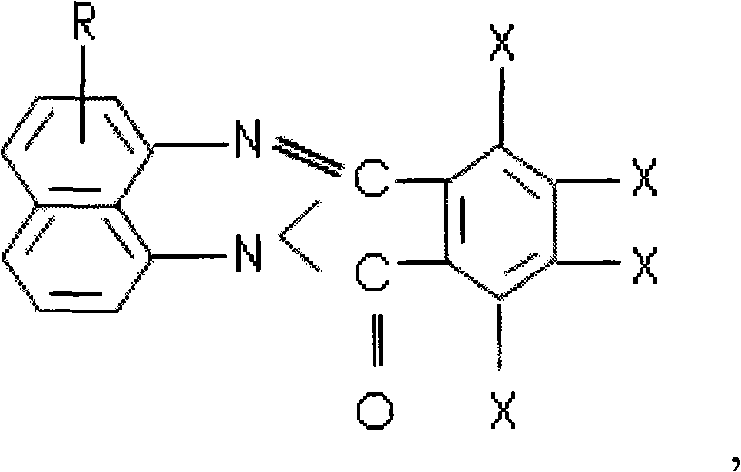

Login to View More Abstract

The invention relates to a red naphtocyclinon solvent dye and a preparation method thereof. The red high-purified solvent dye has a general formula shown in the figure, wherein R is H or CH3 and X is Br or Cl. The solvent dye is prepared by the following steps: condensation reaction of substituted 1,8-diaminonaphthalene and tetrahalogenated benzene at a high temperate in the presence of organic solvents and catalysts, cooling, filtration, refining of the filter cake and drying. The red solvent dye has single component and high purity, is dedicated to dyeing engineering plastics and dyeing polyester fibers before spinning, and has the advantages of good heat resistance, light fastness and acid and alkali resistance, bright color and high transparency. The solvents used in the preparation process are recoverable. The red solvent dye is environment-friendly.

Description

A kind of red naphthyrone solvent dye and preparation method thereof technical field The invention relates to a solvent dye and a preparation method thereof, in particular to a red naphthylcyclone solvent dye used for engineering plastic coloring and polyester fiber pre-spinning coloring and a preparation method thereof. Background technique Solvent dyes are special dyes for polystyrene, ABS, polycarbonate, polyester and other engineering plastics. They have the advantages of bright color, high transparency and good application performance. Some solvent dyes are also important varieties used for pre-spinning coloring of polyester fibers. With the rapid development of engineering plastics, there are higher and higher requirements for heat resistance, light fastness, color brightness, transparency and other indicators. The concept makes the pre-spinning coloring of polyester fibers more and more important. The current red solvent dyes are still insufficient in fastness, t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09B57/00C08J3/20D06P3/52

Inventor 徐斌

Owner 海宁市现代化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com