Solvent green 5 isomer based solvent dye

A solvent-based, organic solvent technology, applied in the field of dyes, can solve the problems of poor high temperature resistance and limited application range, and achieve the effect of simple components and good high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

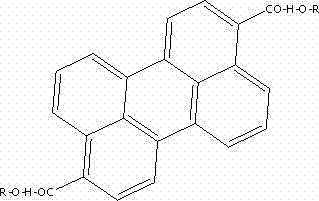

[0043] A solvent-based dye composition, consisting of the following components in mass percentage: 85% of 3,9-diisobutyl perylenedicarboxylate, 15% of 3,10-diisobutyl perylenedicarboxylate, wherein , The molecular formulas of 3,9-diisobutyl perylenedicarboxylate and 3,10-diisobutyl perylenedicarboxylate are shown in formulas (I) and (II):

[0044]

[0045] (I)

[0046]

[0047] (II),

[0048] Among them, R=C 4 h 8 ,

[0049] The preparation method of this solvent type dye composition is:

[0050] (1) Preparation of 3,9-perylenedicarboxylic acid and 3,10-perylenedicarboxylic acid

[0051] Dissolve 3,4,9,10-perylenetetracarboxylic anhydride in KOH solution first, then raise the temperature to 198°C, keep it under the condition of 2MPa for 36 hours, then lower the temperature and lower the pressure, wait until the pressure drops to normal pressure, the temperature drops After reaching 85°C, perform hot filtration, and finally adjust the pH of the filtrate to 4 with h...

Embodiment 2

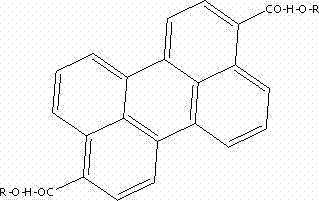

[0061] A solvent-based dye composition, consisting of the following components in mass percentage: 87% of 3,9-diisobutyl perylenedicarboxylate, 13% of 3,10-diisobutyl perylenedicarboxylate, wherein , The molecular formulas of 3,9-diisobutyl perylenedicarboxylate and 3,10-diisobutyl perylenedicarboxylate are shown in formulas (I) and (II):

[0062]

[0063] (I)

[0064]

[0065] (II),

[0066] Among them, R=C 4 h 8 ,

[0067] The preparation method of this solvent type dye composition is:

[0068] (1) Preparation of 3,9-perylenedicarboxylic acid and 3,10-perylenedicarboxylic acid

[0069] First, dissolve 3,4,9,10-perylenetetracarboxylic anhydride in KOH solution, then raise the temperature to 200°C, keep the temperature at 2.05MPa for 38 hours, then lower the temperature and pressure, and wait until the pressure drops to normal pressure. After cooling down to 88°C, perform hot filtration, and finally adjust the pH of the filtrate to 4.2 with hydrochloric acid and t...

Embodiment 3

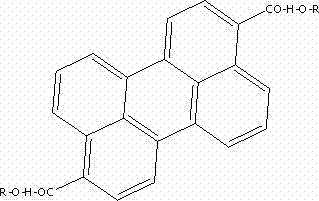

[0079] A solvent-based dye composition, consisting of the following components in mass percentage: 88% 3,9-diisobutyl perylenedicarboxylate, 12% 3,10-diisobutyl perylenedicarboxylate, wherein , The molecular formulas of 3,9-diisobutyl perylenedicarboxylate and 3,10-diisobutyl perylenedicarboxylate are shown in formulas (I) and (II):

[0080]

[0081] (I)

[0082]

[0083] (II),

[0084] Among them, R=C 4 h 8 ,

[0085] The preparation method of this solvent type dye composition is:

[0086] (1) Preparation of 3,9-perylenedicarboxylic acid and 3,10-perylenedicarboxylic acid

[0087] First, dissolve 3,4,9,10-perylenetetracarboxylic anhydride in KOH solution, then raise the temperature to 203°C, keep it under the pressure of 2~2.1MPa for 36~40h, then lower the temperature and pressure, and wait until the pressure drops to Atmospheric pressure, after the temperature drops to 90°C, perform hot filtration, and finally adjust the pH of the filtrate to 4.5 with hydrochlor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com