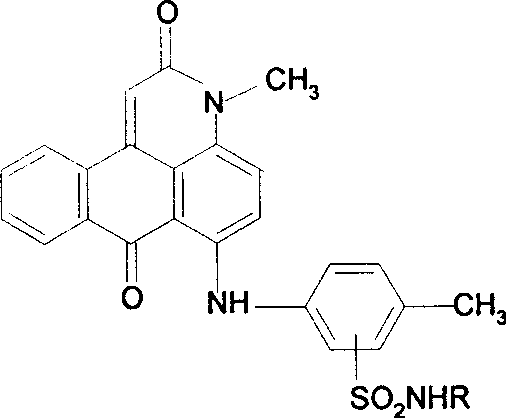

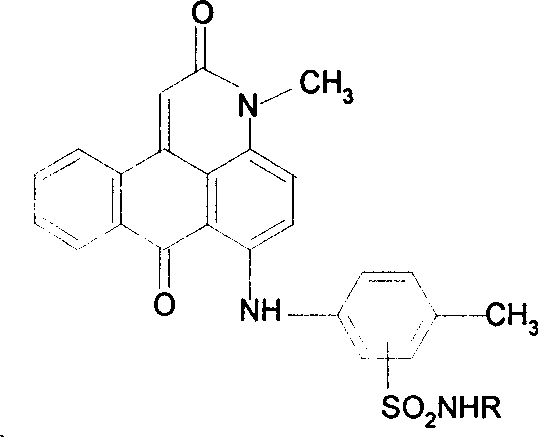

Anthrapyridone solvent dye and synthetic method thereof

A solvent dye and anthrapyridone technology, which is applied in the synthesis field of anthrapyridone solvent dyes, can solve the problems such as heat resistance and migration resistance to be improved, and achieves wide application range, improved heat resistance and migration resistance, The effect of high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

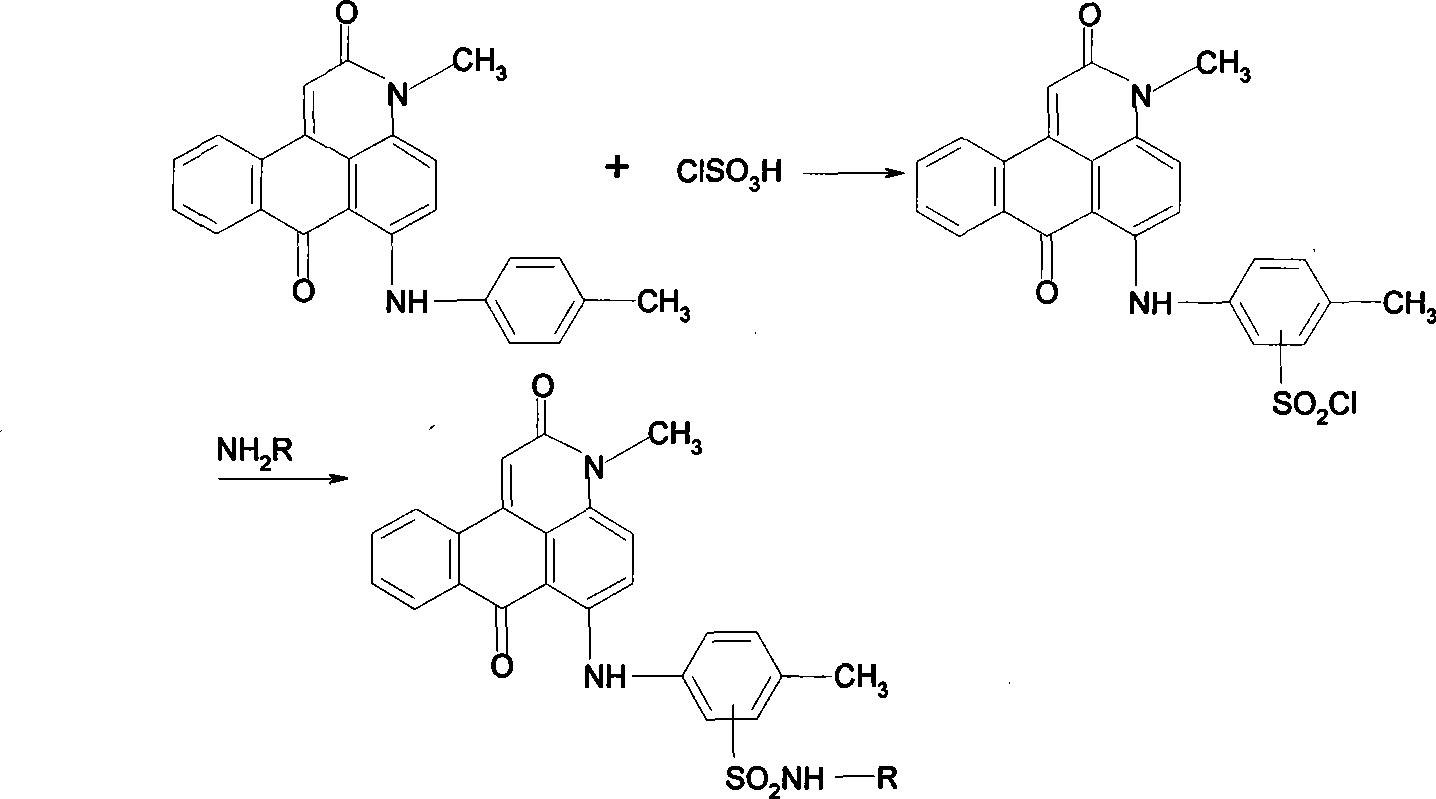

Method used

Image

Examples

Embodiment 1

[0018] In a 250ml three-necked flask, add 160g of chlorosulfonic acid, start stirring, and slowly add 20g of solvent red 52, the temperature does not exceed 25°C. After the addition, the temperature was carefully raised to 35°C and kept at 35°C for 1 hour. Dilute the material into 1000 g of crushed ice, filter with suction, and wash the filter cake with ice water until slightly acidic. The chlorosulfonated filter cake is beaten with 500 grams of ice water, adjusted to pH 6.5-7.0 with 10% sodium carbonate solution, and 15 grams of cyclohexylamine is added dropwise to control the temperature below 10°C. After the dropwise addition, start to add 20 grams of 10% sodium carbonate solution dropwise, finish dropping in 1 hour, control the pH between 9.5 and 11.5, keep it below 10°C for 4 hours, then warm up to room temperature, and continue the reaction for 3 hours. Finally, raise the temperature to 60-70°C, keep it for 30 minutes, filter, and wash the filter cake with water at abou...

Embodiment 2

[0020] In a 250ml three-necked flask, add 120g of chlorosulfonic acid, start stirring, and slowly add 20g of solvent red 52, the temperature does not exceed 15°C. After the addition, the temperature was carefully raised to 35°C and kept at 35°C for 1 hour. Then 20 grams of thionyl chloride was added dropwise and stirred for 30 minutes. Dilute the material into 1000 g of crushed ice, filter with suction, and wash the filter cake with ice water until slightly acidic. Slurry the chlorosulfonated filter cake with 200 grams of ice and 300 grams of water, adjust the pH to 6.5-7.0 with 10% sodium carbonate solution, add a solution of 12.5 grams of aniline and 15 grams of methanol dropwise, keep the temperature at 10°C, and start to add 20 grams of 10% sodium carbonate solution, pH between 9.5 and 11.5, dripped in about 2 hours. Stirred at 10°C for 4 hours, then warmed to room temperature, and continued the reaction for 3 hours. Finally, raise the temperature to 60-70°C, keep it fo...

Embodiment 3

[0022] In a 250ml three-neck flask, add 150g of chlorosulfonic acid, start stirring, slowly add 20g of solvent red 52, the temperature does not exceed 25°C, after the addition, stir at room temperature for 2 hours. Dilute the material into 1000 grams of crushed ice, filter with suction, and wash the filter cake with ice water until it is nearly neutral. The filter cake is beaten with a solution of about 200 grams of ice and 200 grams of ethanol, the temperature is controlled at 3 ° C, and the pH is adjusted to 6.5 to 7 with 10% sodium carbonate solution, and a solution of 20.5 grams of p-toluidine dissolved in 35 grams of ethanol is started to be added dropwise. At the same time, 22 grams of 10% sodium carbonate solution was added dropwise, the temperature was controlled below 15° C., and the pH was between 9.5 and 11.5. After the dropwise addition, continue to stir for 5 hours, then raise the temperature in a water bath to 50°C, stir for 30 minutes, filter, wash the filter ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com