Dyeing technology of poly(butylene succinate) fibers

A polybutylene succinate and fiber technology, which is applied in the field of polymer dyeing and finishing, can solve problems such as poor heat resistance and thermal stability, and achieve the effect of improving use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

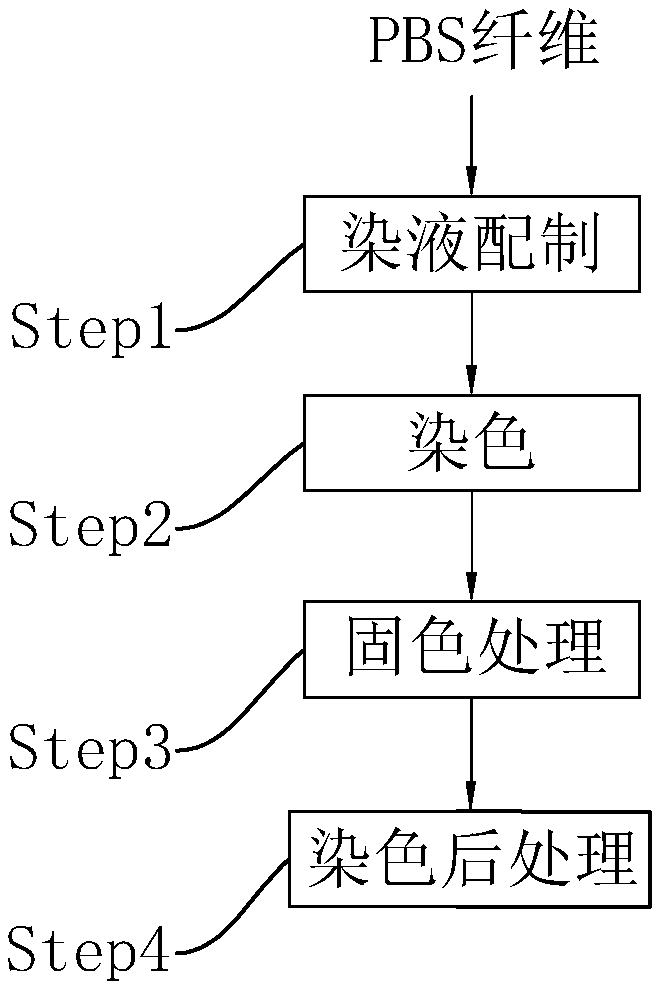

[0039] refer to figure 1 , a kind of dyeing process of polybutylene succinate fiber, PBS fiber is carried out following steps processing;

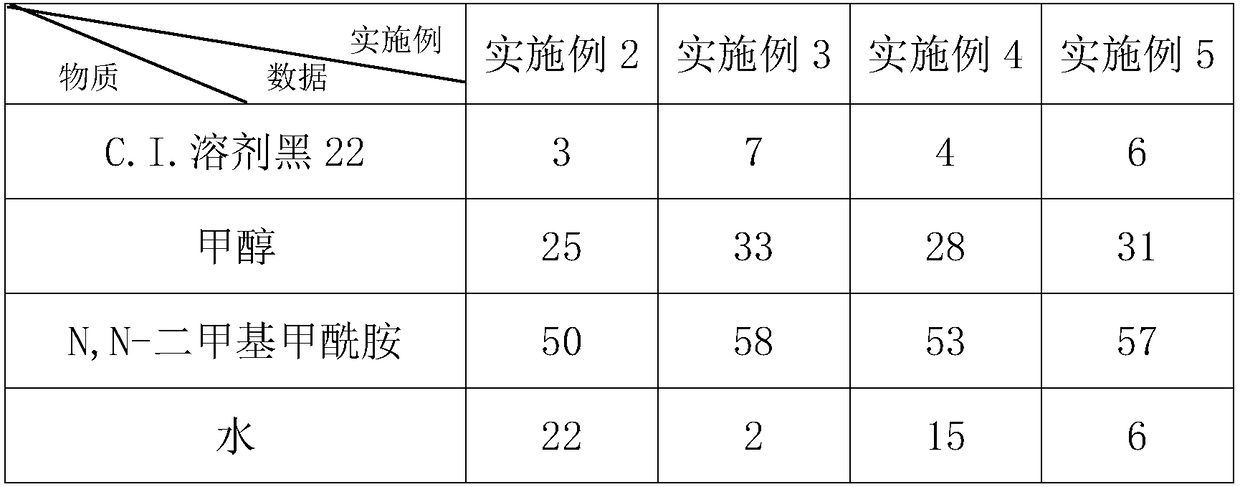

[0040] Step1: Dye liquor preparation; each substance in the dye liquor is calculated by mass percentage: solvent dyestuff is 5%, methanol 30%, N,N-dimethylformamide 55%, and water 10%; Wherein the purity of methanol is 100%, the purity of N,N-dimethylformamide is 100%, and the solvent dye used is C.I. Solvent Black 22. Simultaneously, the preparation of the dye solution comprises the following steps;

[0041] a. First add methanol with a mass fraction of 30% in the container, then slowly add C.I. Solvent Black 22 with a mass fraction of 5% to the container containing methanol, and keep stirring during the addition of C.I. Solvent Black 22 until completely dissolved.

[0042]b. After the C.I. solvent black is completely dissolved in methanol, slowly add 55% N,N-dimethylformamide to the container, and keep stirring during the addition unt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com