Microbead latex ink and preparation method thereof

A technology of ink and emulsion, applied in the direction of ink, household utensils, applications, etc., to achieve the effect of uniform particle size distribution and good dispersion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

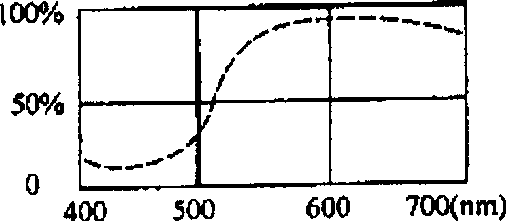

[0063] Preparation of magenta ink

[0064] Formulation composition (weight percent)

[0065] Red solvent dye raw material (C.I. solvent red 49) 0.5%, toluene 15%, polyoxyethylene ether nonionic surfactant ET-135 10%, glycerol 1%, AMP-95 0.1%, n-propanol 35% , preservatives such as phenol 0.1%, deionized water 38.3%.

[0066] Preparation:

[0067] Mix the red solvent dye and toluene at room temperature, and disperse for 10 minutes on a high-speed dispersing homogenizer (Shanghai Beierte Electromechanical Equipment Technology Co., Ltd.) to obtain a mixed solution;

[0068] Mix ET-135, glycerol, AMP-95, n-propanol, preservatives, and deionized water at room temperature, and stir at high speed for 1 hour to obtain a mixed solution;

[0069] The above two mixed solutions were mixed and stirred at high speed for 1.5 hours, homogenized for 10 minutes, and filtered with a 0.2 micron filter membrane to remove impurities to obtain the final product.

Embodiment 2

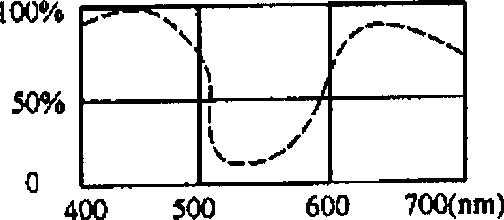

[0071] Preparation of yellow ink

[0072] Formulation composition (weight percent)

[0073] Yellow solvent dye raw material (C.I. Solvent Yellow 88) 1%, xylene 5%, surfactant (ET-135) 5%, propylene glycol 6%, AMP-955%, n-propanol 16%, preservative benzoic acid 2% , 60% deionized water.

[0074] The preparation method is the same as in Example 1.

[0075] The specific structure includes long-chain fatty alcohol polyoxyethylene ether, alkylphenol polyoxyethylene ether, fatty acid polyoxyethylene ester, fatty amine polyoxyethylene ether, fatty acyl alkanolamine, fatty acyl alkanolamine polyoxyethylene ether, castor Sesame oil ethylene oxide adduct, etc.

Embodiment 3

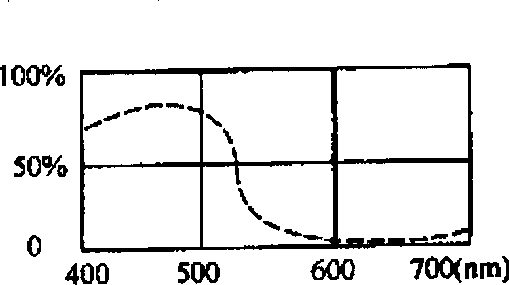

[0077] Preparation of cyan ink

[0078] Formulation composition (weight percent)

[0079] Cyan solvent dye raw material (C.I. solvent blue 70) 3%, cyclohexanone 31%, surfactant (ET-135) 1%, ethylene glycol 10%, diethanolamine 2%, n-propanol 20%, isopropanol 7%, preservative sodium benzoate 1%, deionized water 25%.

[0080] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com