Boiling-resistant color master batch, preparation method and applications thereof

A water-resistant and color masterbatch technology, which is applied in the field of nylon color masterbatch, can solve the problems of large color difference, achieve more colorful, bright and uniform colors, and meet the effects of product performance and appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5 and comparative example 1-4

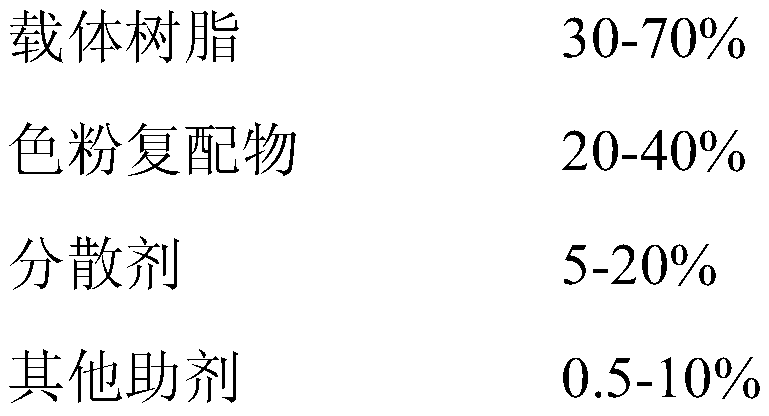

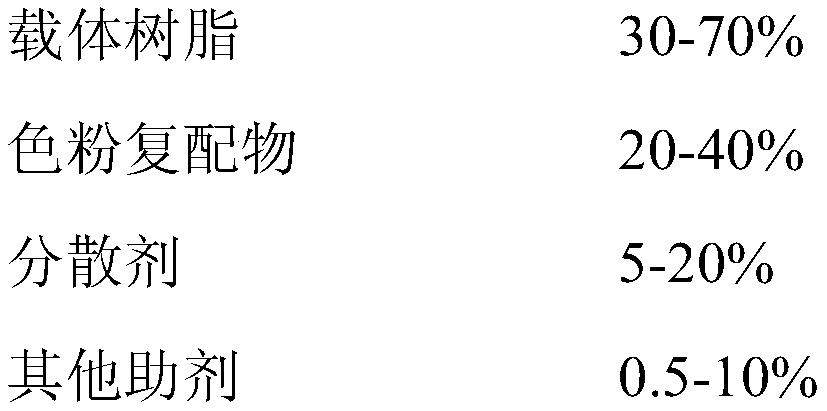

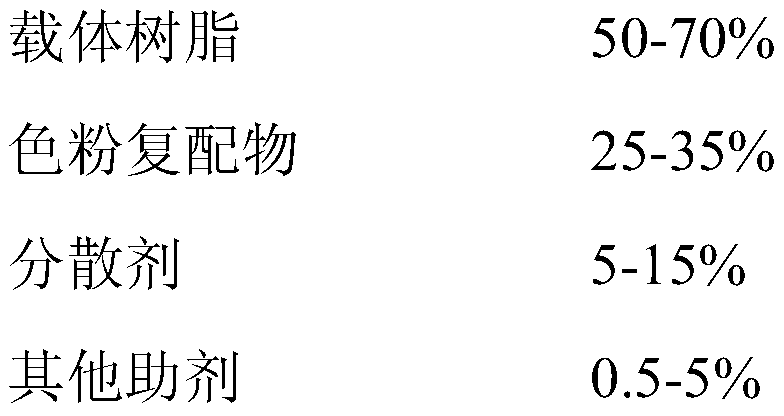

[0037] The composition of raw materials in Examples and Comparative Examples is shown in Table 1 by weight percentage.

[0038] Raw material composition in the embodiment and comparative example of table 1

[0039]

[0040]Mix the toner compound and dispersant evenly according to the composition of the above raw materials, then mix them again with the carrier resin and other additives, and then add them to the twin-screw extruder for melt blending. The extrusion temperature is 230°C. Strips, air-dried and granulated to obtain the boil-resistant color masterbatch.

[0041] Add 1wt% of the prepared water-resistant masterbatch to the nylon preparation, blend and granulate, directly inject the obtained colored particles into a color plate, measure the color difference before and after boiling, and judge the water-resistant property of the prepared water-resistant color masterbatch.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com